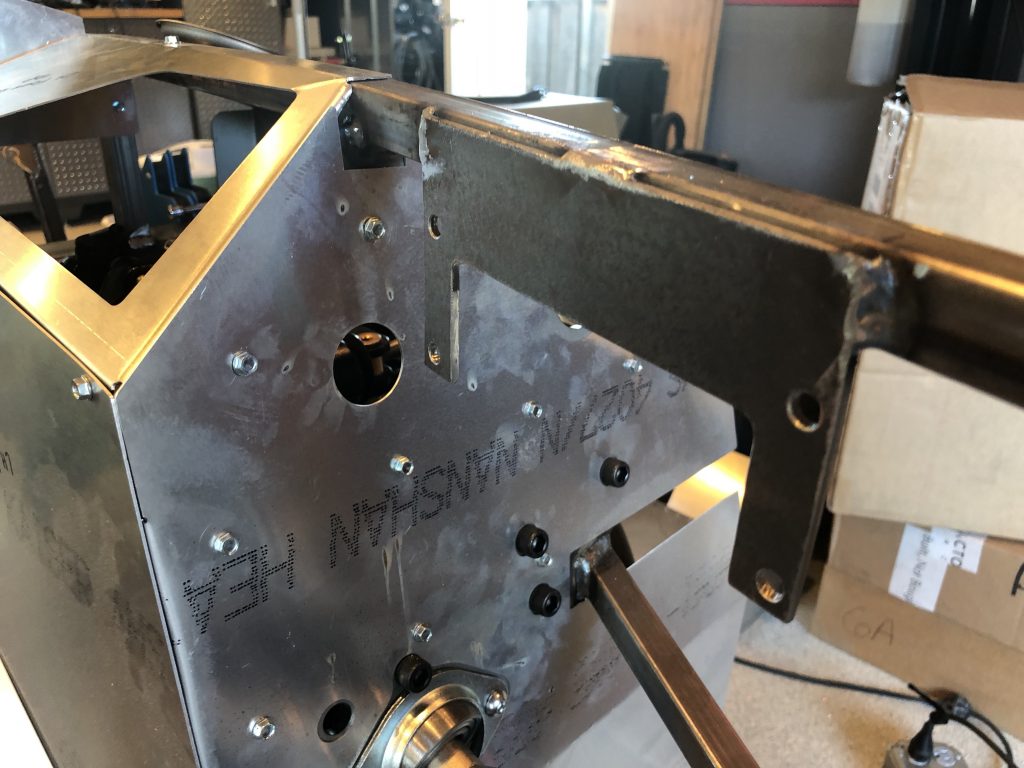

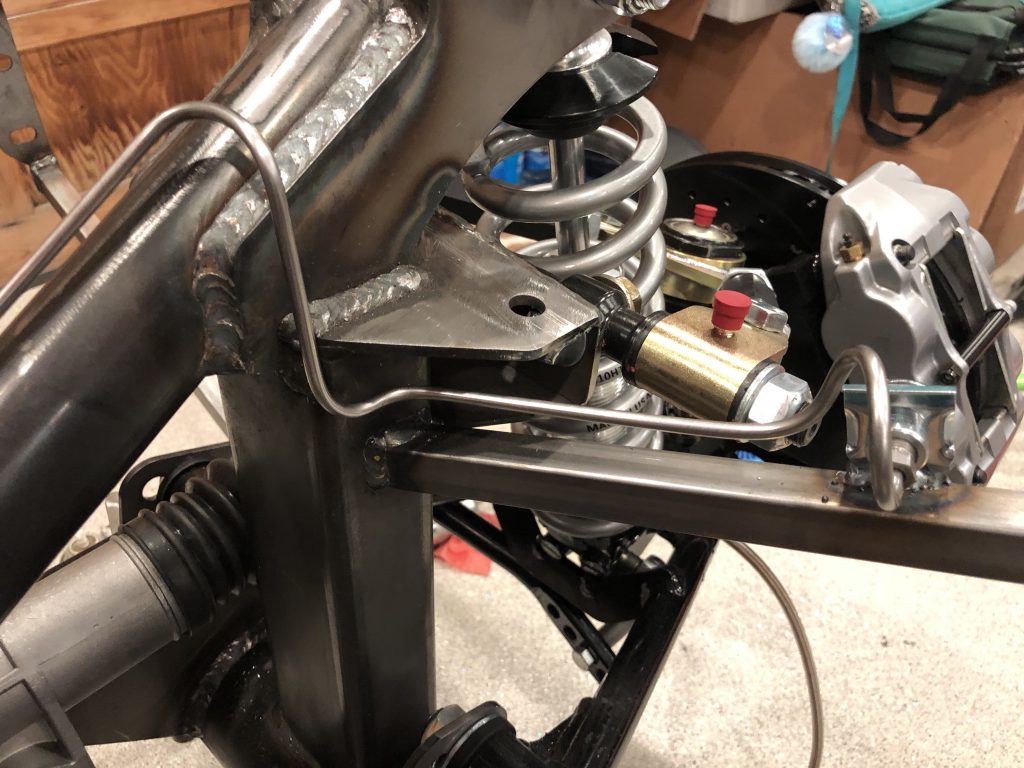

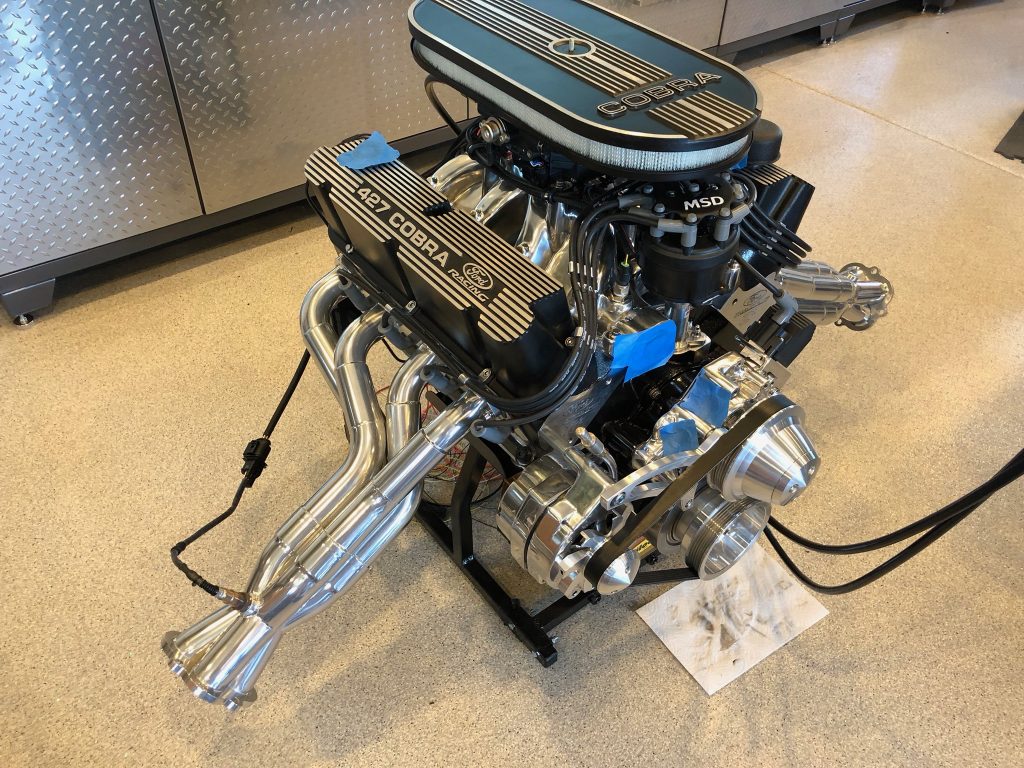

I met my dad down at Dino Fry’s racing shop this morning. Almost immediately, he suggested canceling the dyno run because he had no way to connect his exhaust tubes (the flexible stainless tubing at the bottom left of this picture) to my headers. He suggested ordering a couple of the end flanges from the exhaust manufacturer and welding some 90º elbows onto them to turn the exhaust aft. That could take weeks, so I began suggesting alternatives. He ended up agreeing to weld on the tubing if we purchased it and I could fabricate some exhaust flanges.

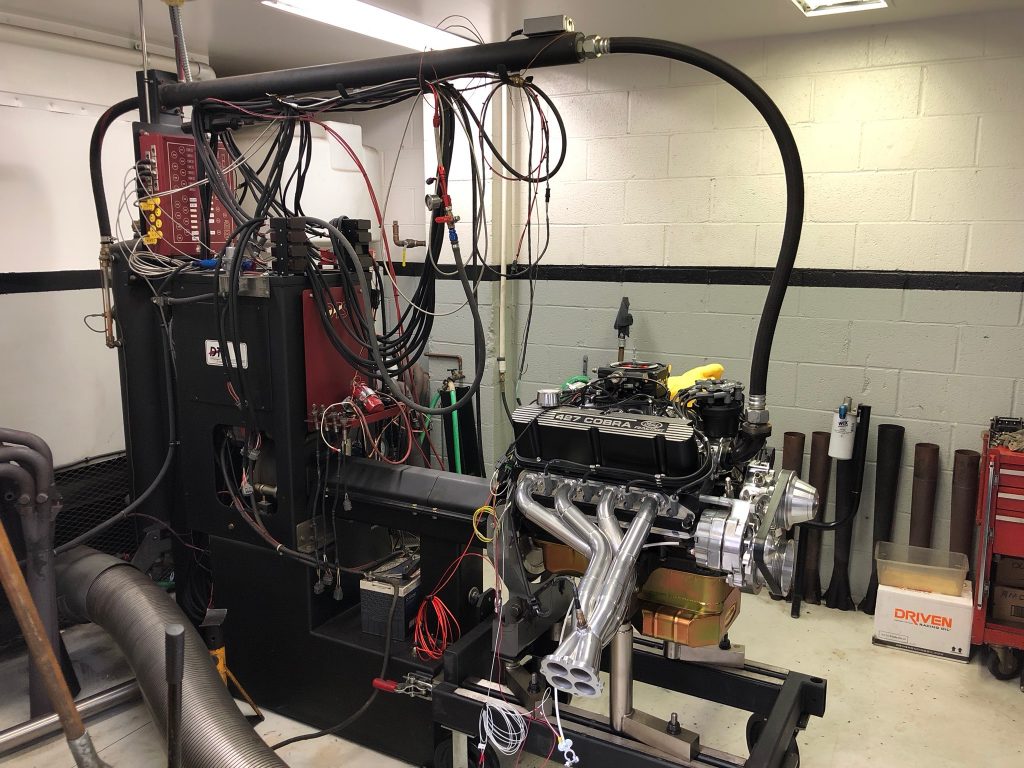

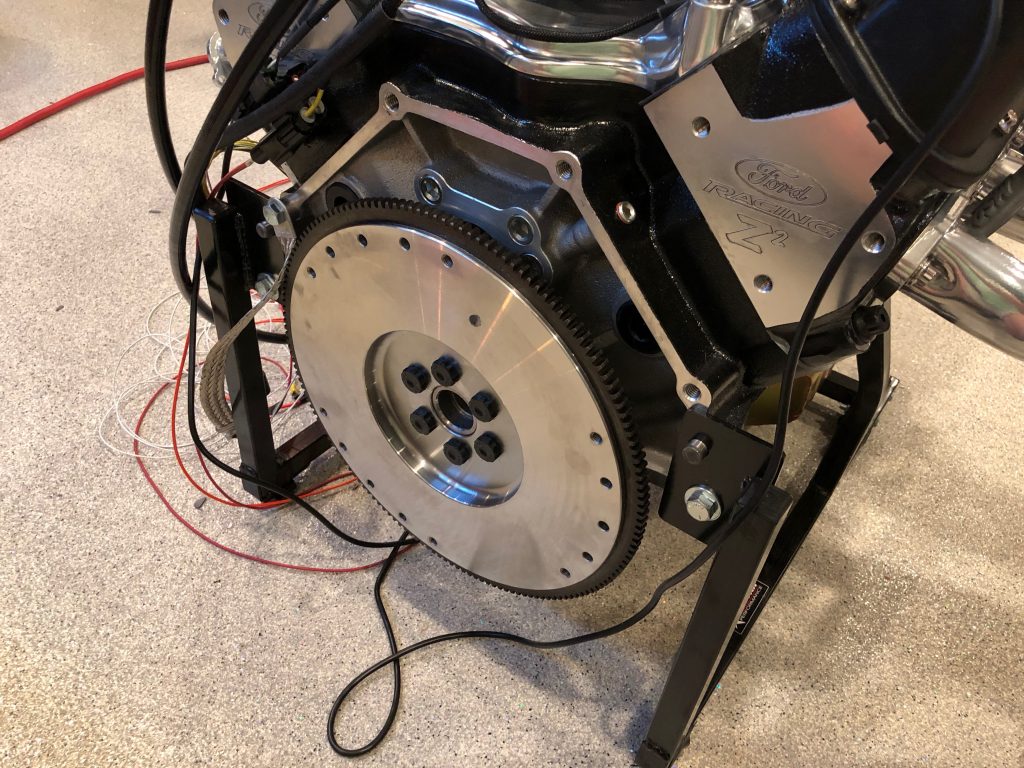

My dad headed over to a diesel semi exhaust shop that had the right tubing in stock and I headed to the TechShop to fabricate the flanges. While we were gone, Dino installed the engine on the dyno.

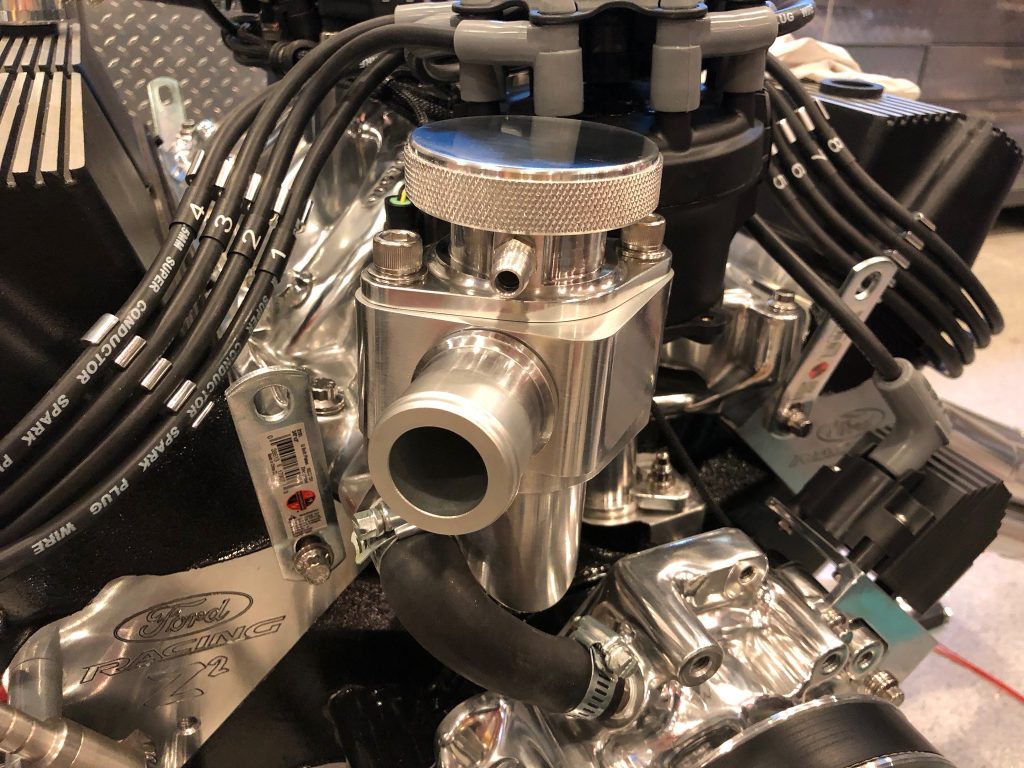

It turns out that I didn’t need to install the water neck as he needed to remove it anyway.

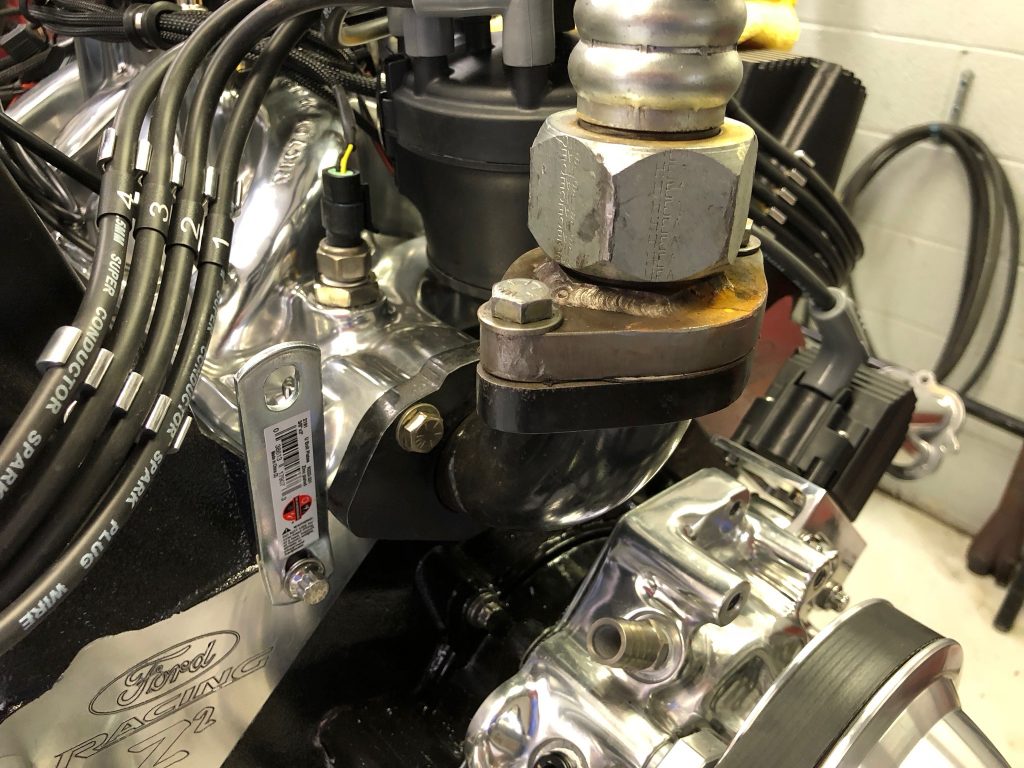

After lunch, Dino welded on the elbows and a piece of straight tubing. This is 5″ diameter tubing. The two elbows and straight pipes ran about $140. Sucks to spend this much on a one-time use part, but there were no other good options.

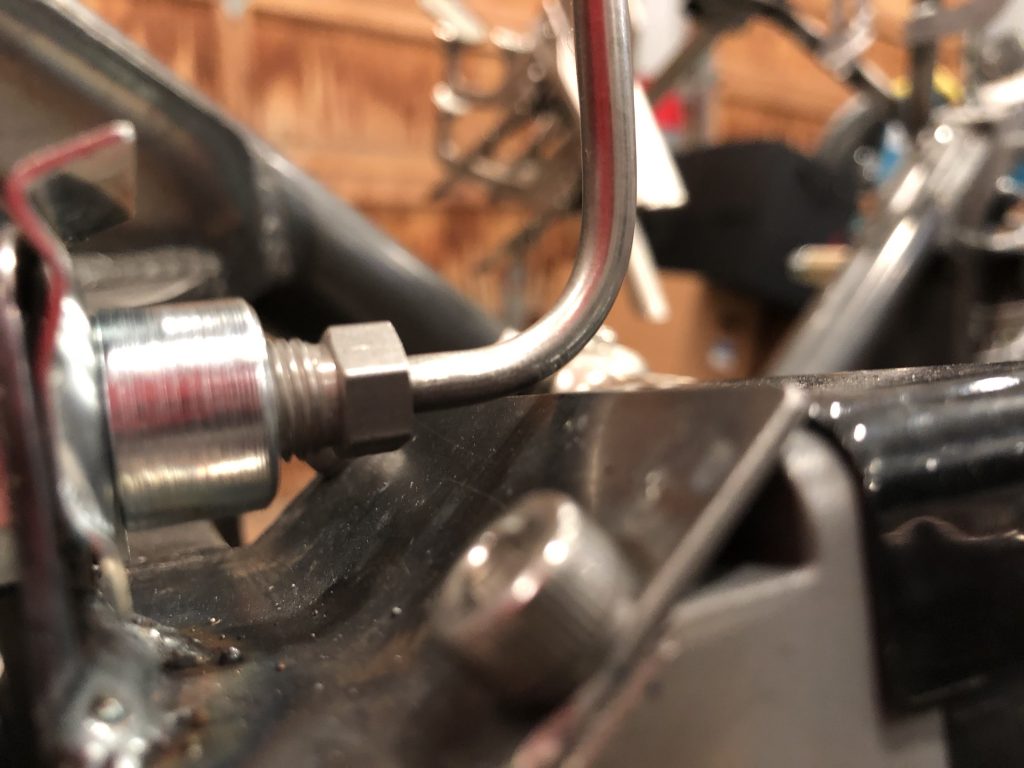

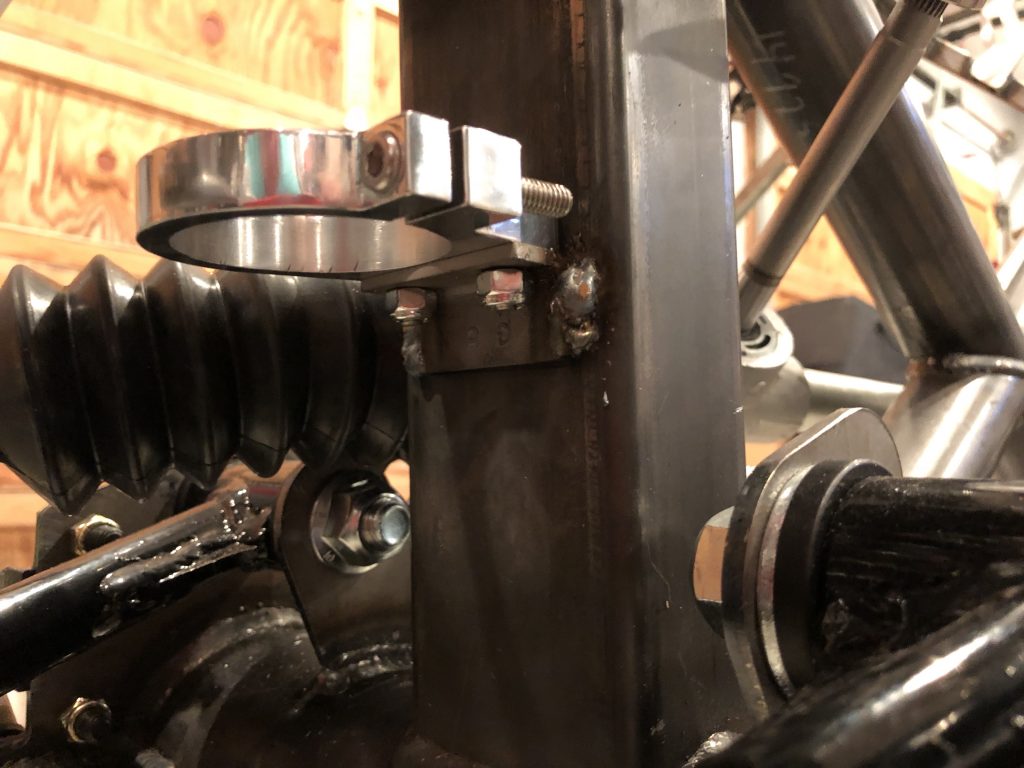

After welding the flange in place, Dino heated up the pipes and dented it in to make room for the bolts. After they cooled down, we bolted them to the exhaust headers.

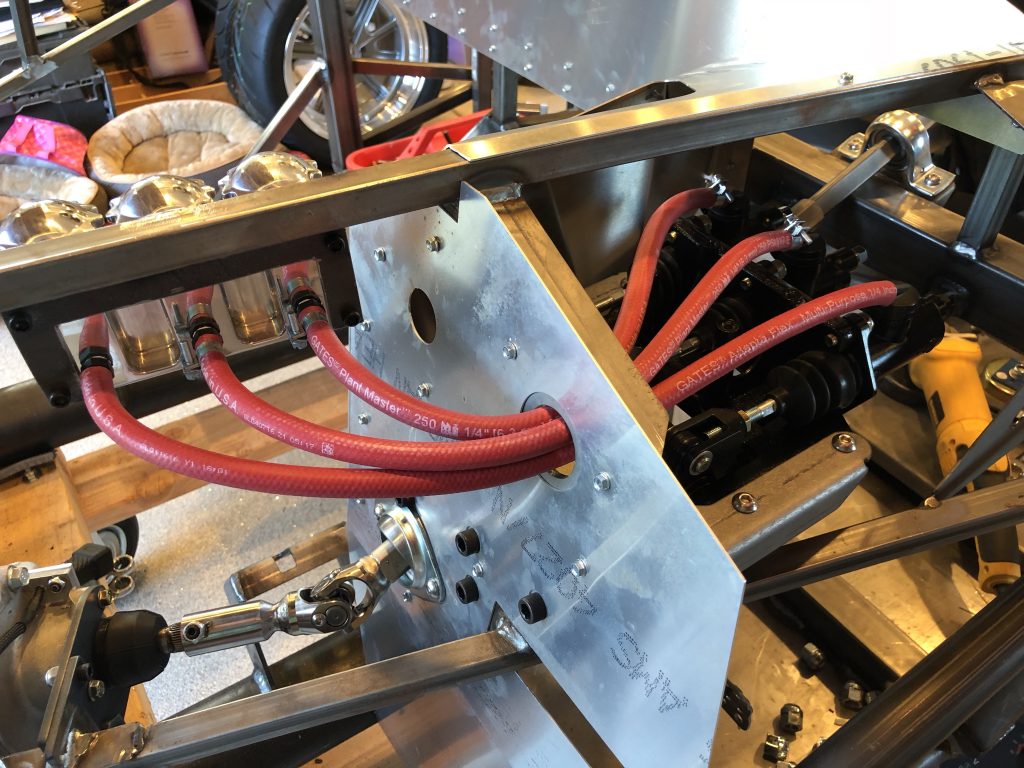

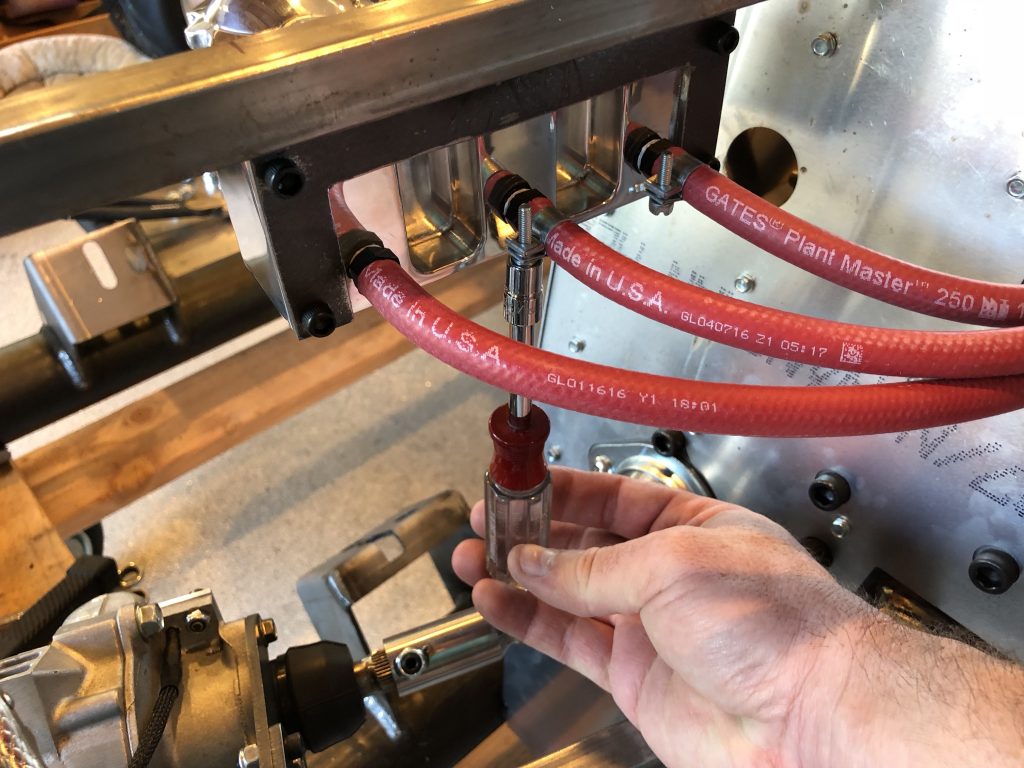

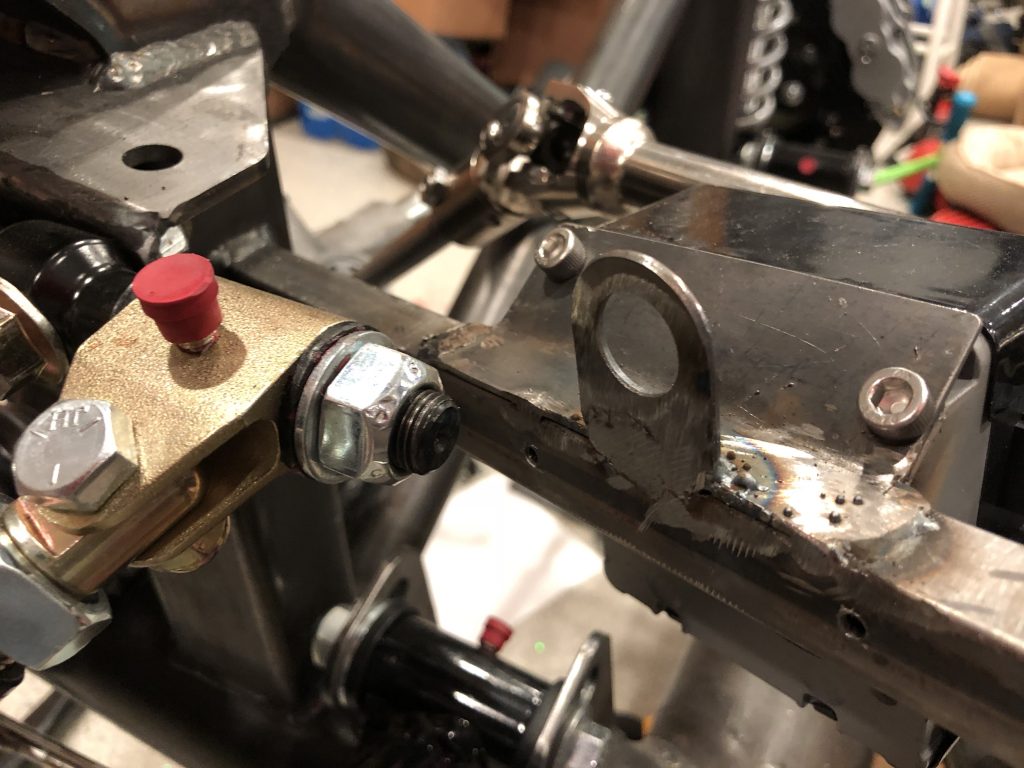

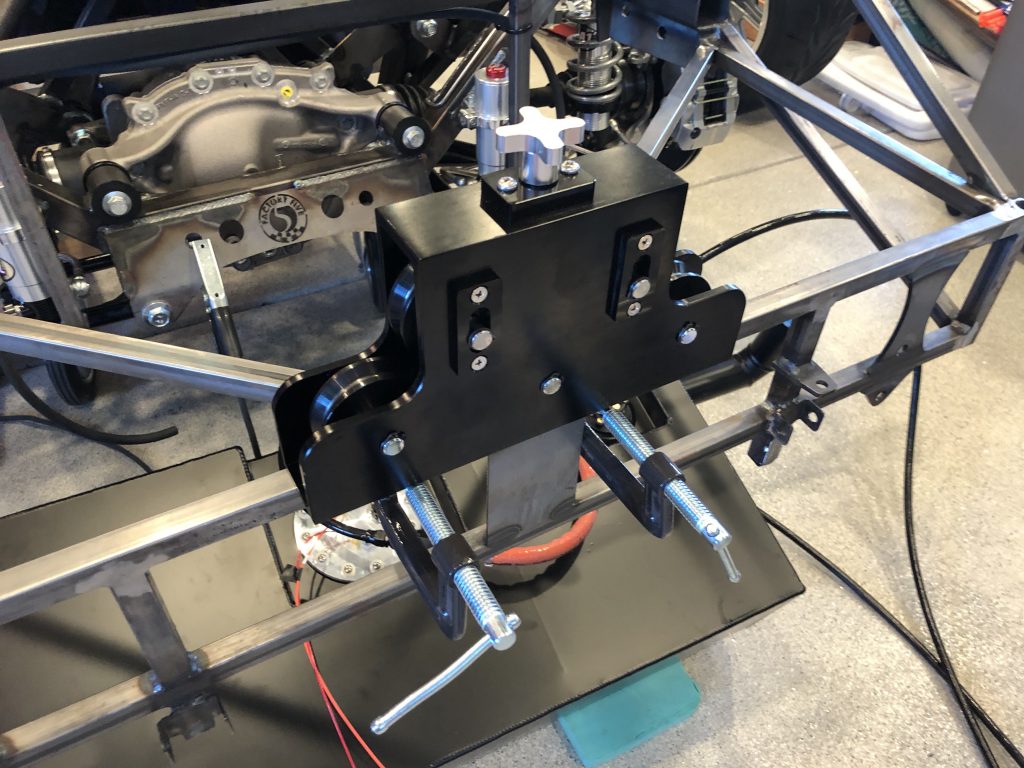

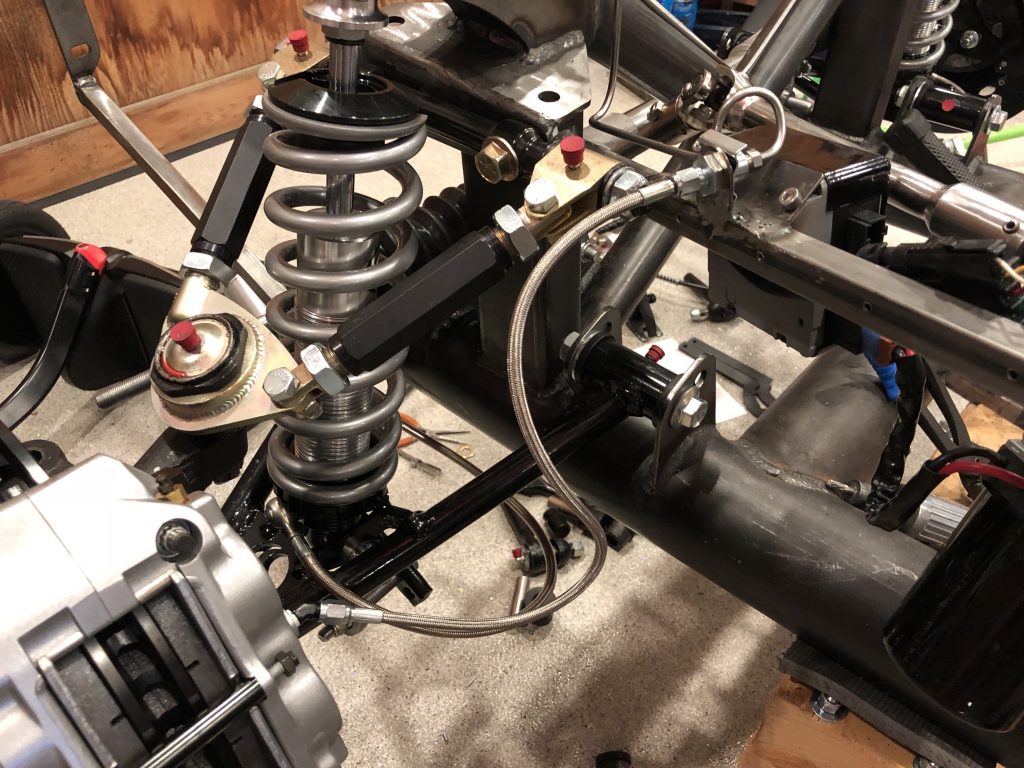

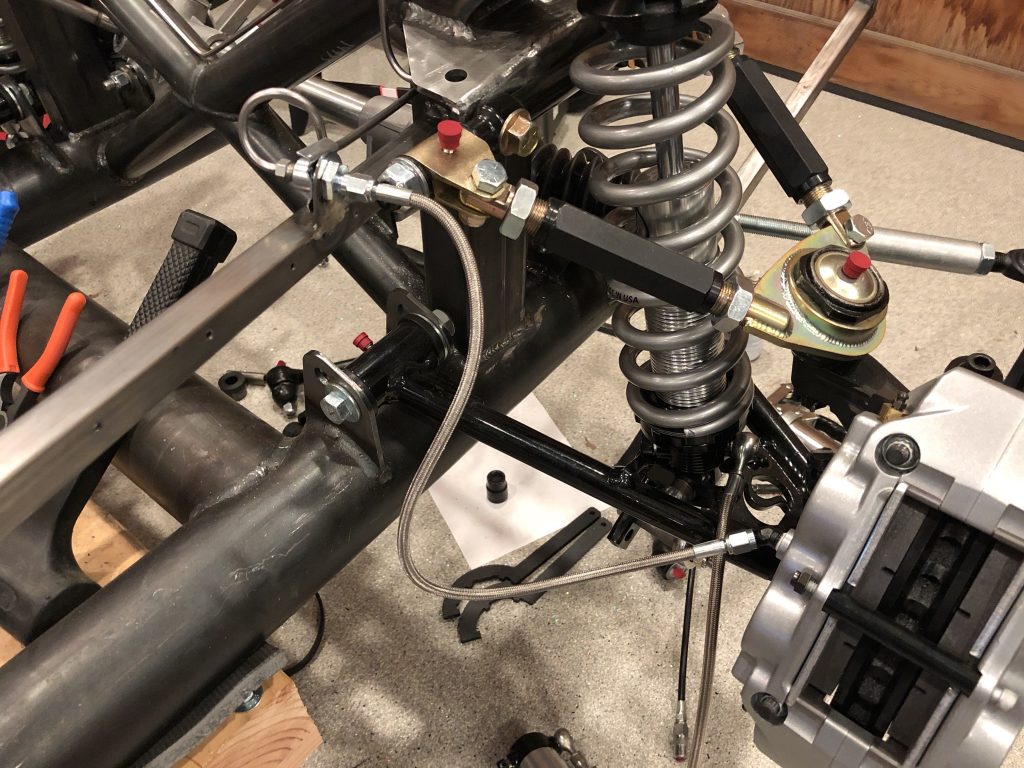

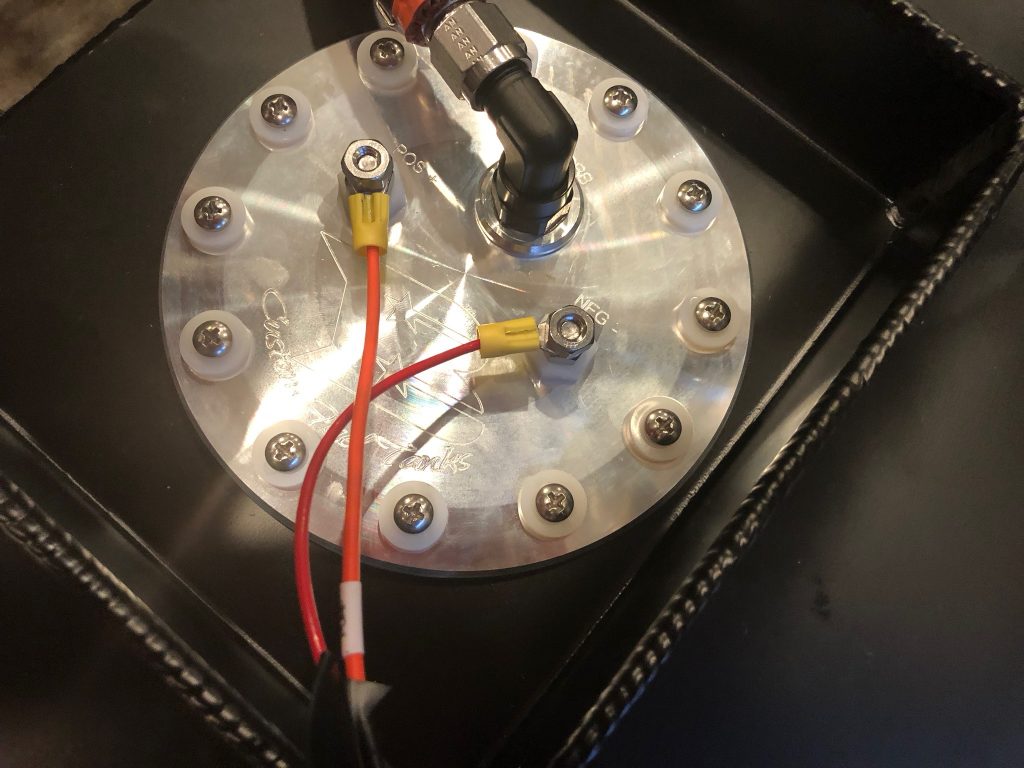

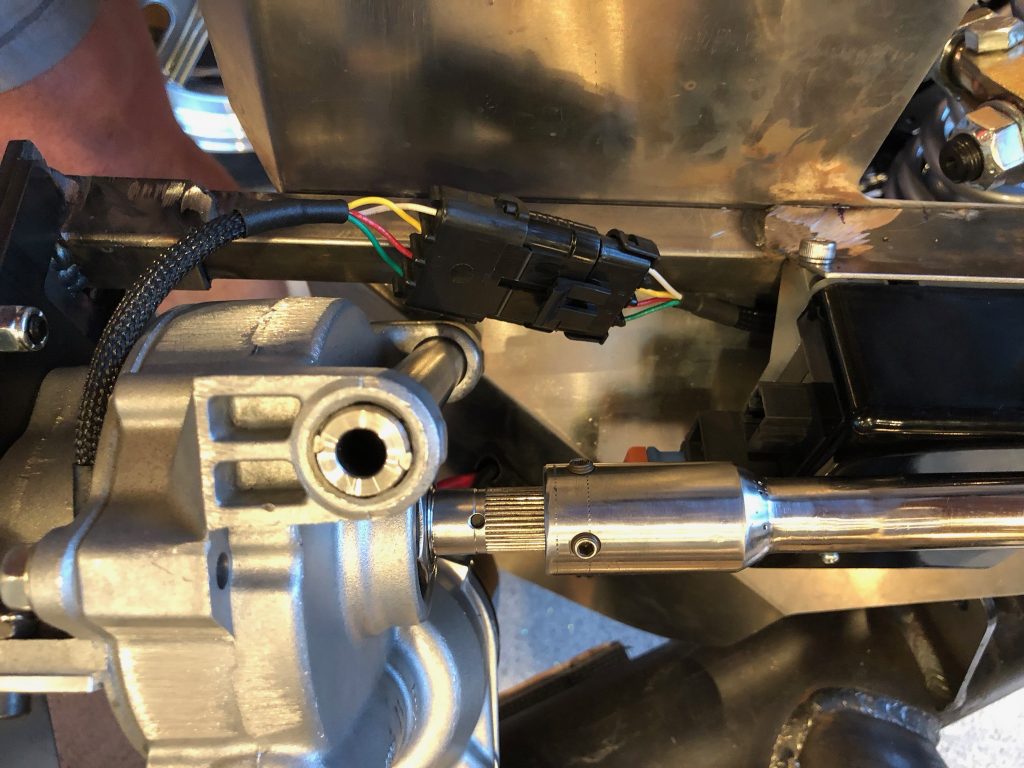

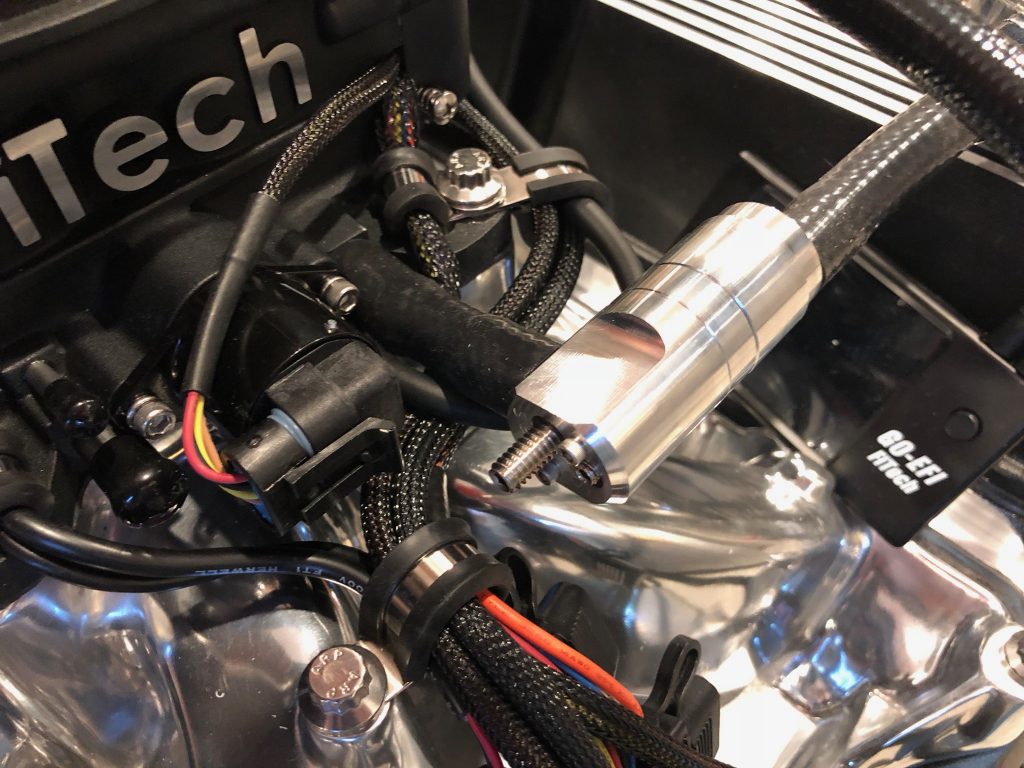

We moved my fuel tank in place and finished up the fuel, electrical and water connections. This thing is ready to run!

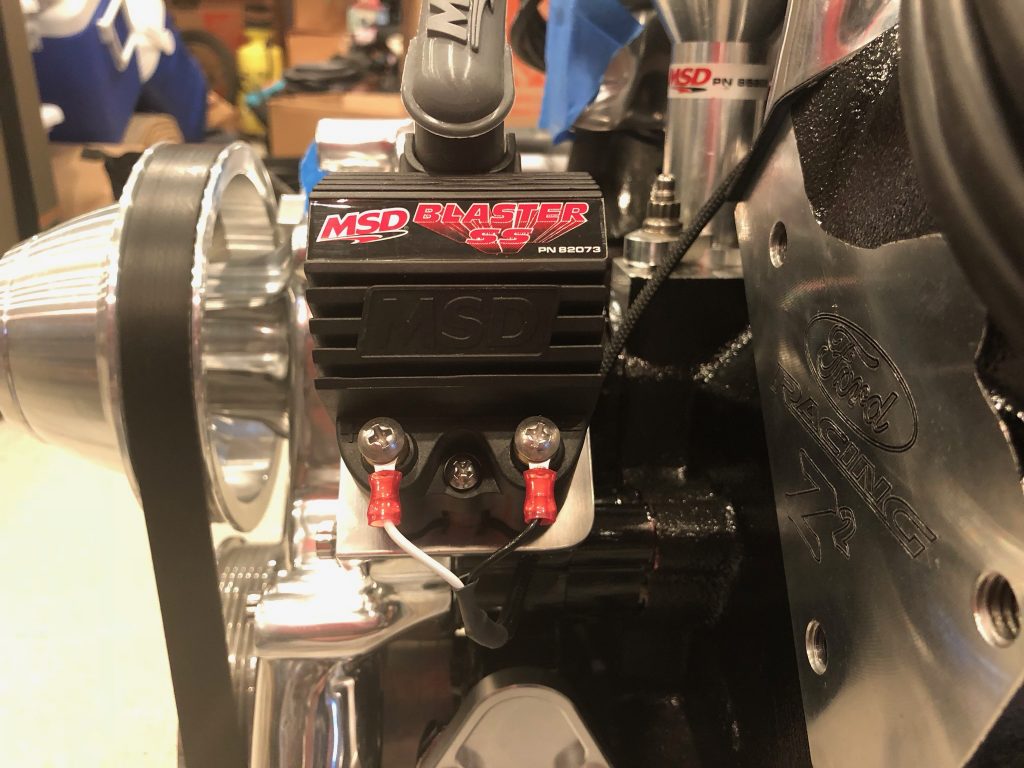

After a couple of failed start attempts, we realized that we weren’t getting spark. I quickly diagnosed that the FiTech config was wrong and I needed to let it know that we were using a two-wire distributor and external coil. Once that was done, the engine fired on the first turn of the crank!

After a 30 minute break-in at 2000rpm, we shut down and pulled all the plugs to confirm there were no problems that needed to be addressed. Everything looked good, so we reinstalled the plugs and got the engine ready for the first dyno pull. Here’s a video of the first pull. The engine had cooled off significantly since we shut down for so long, so we needed to let it warm up for over 6 minutes. In the video, you can see how quickly the engine fires and how smoothly it runs at higher rpms. You can also get a good sense of how lopey the idle is (which is exactly what we were looking for). I was a little concerned that the idle would be too smooth with a 114º lobe separation, but it sounds fantastic. Most of the video is just the warmup; if you want to skip ahead, the dyno pull itself happens in the last 45 seconds.

We did a total of 8 dyno pulls today while adjusting ignition advance and the accel pump setting. We saw about 465hp and 480 lbf-ft of torque on the best run, but I think we’ll be able to improve that a bit when we finish tuning the engine tomorrow.