In preparation for resuming work on the car, I wanted to improve the tooling I have for metal work. I was fortunate to have a friend give me a Precision Matthews PM-25MV bench top mill he was no longer using. I added a couple of upgrades to the mill including a power feed on the x-axis and a quill stop and quill lock (not pictured).

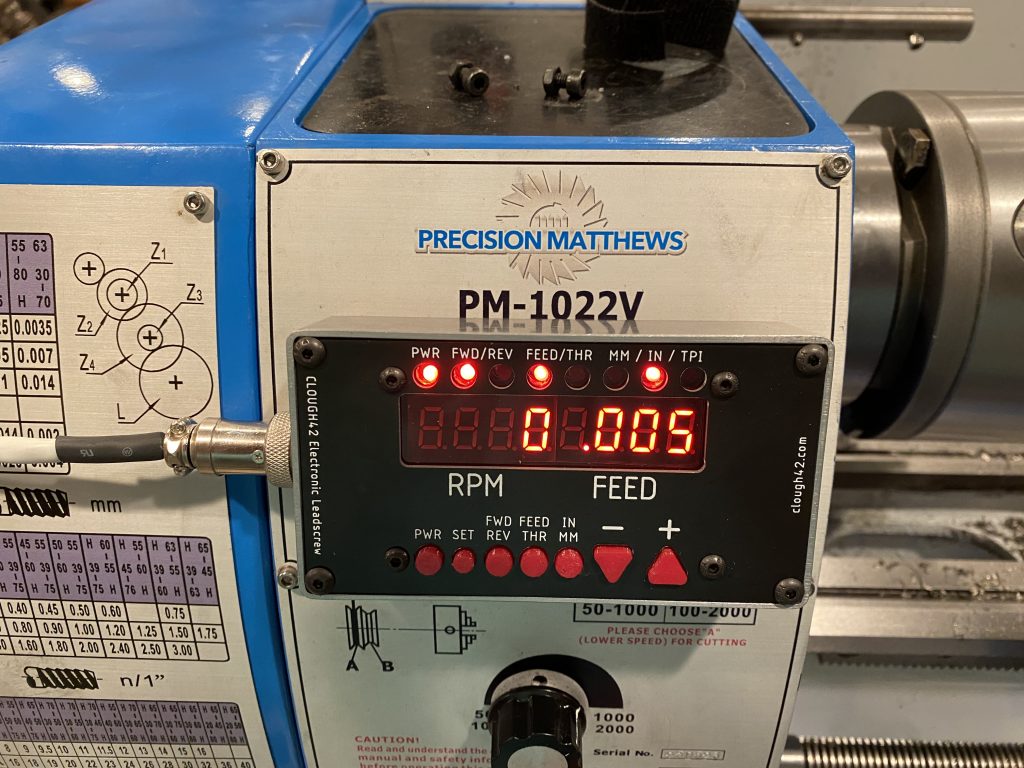

I also decided to add a lathe to the shop since I’ve already needed a lathe for a few tasks on the car. I don’t have a ton of space, so I picked up a Precision Matthews PM-1022V lathe and mounted it on an identical tool box.

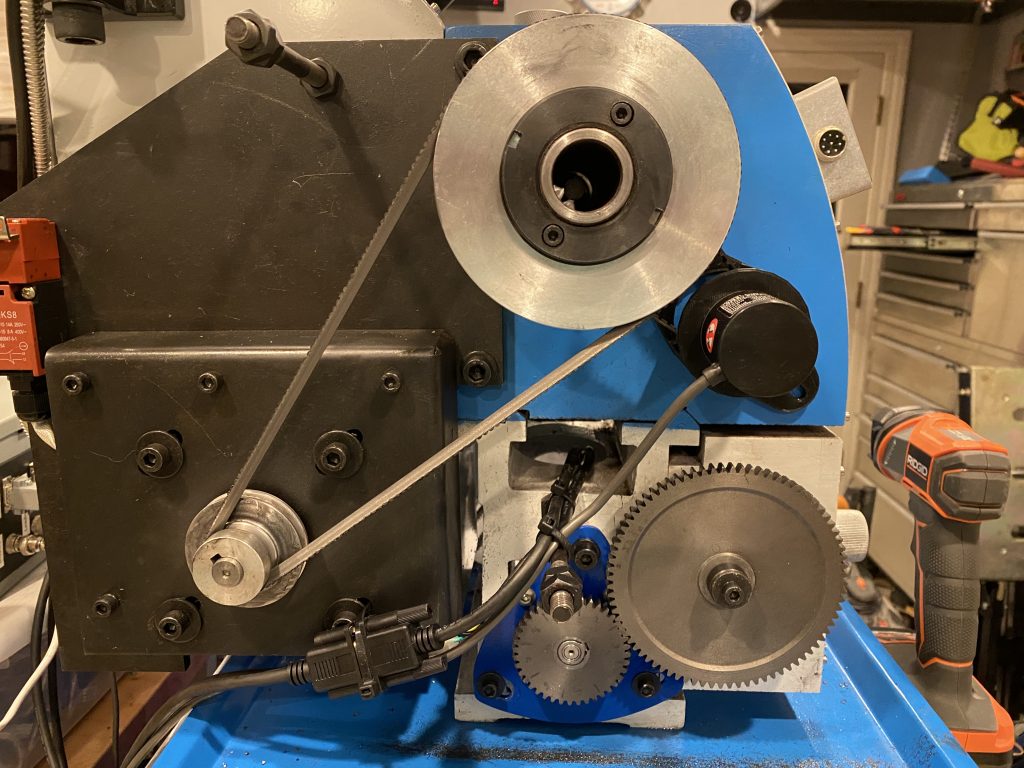

These small lathes have relatively simple gearboxes, so they use a set of change gears that must be swapped to change the feed rate or for any threading operation. I didn’t like the thought of having to mess with that, so I installed an electronic lead screw. This was designed by James Clough but requires a custom installation on each machine. It uses an optical encoder to read the spindle position and then a microcontroller controls a servo to drive the leadscrew.

This lets you switch between forward/reverse, feeding/threading, and inch/mm units at the touch of a button and change the feed rate on the fly as well as simply selecting the threading pitch on the screen (for both SAE and metric threads). This should be a nice upgrade for this little lathe.