Sadly, the engine makes exactly the same sound with the new lifters. Either we didn’t get the preload set right on these lifters, or the problem is a bad rocker or pushrod. I’ll continue the diagnosis…

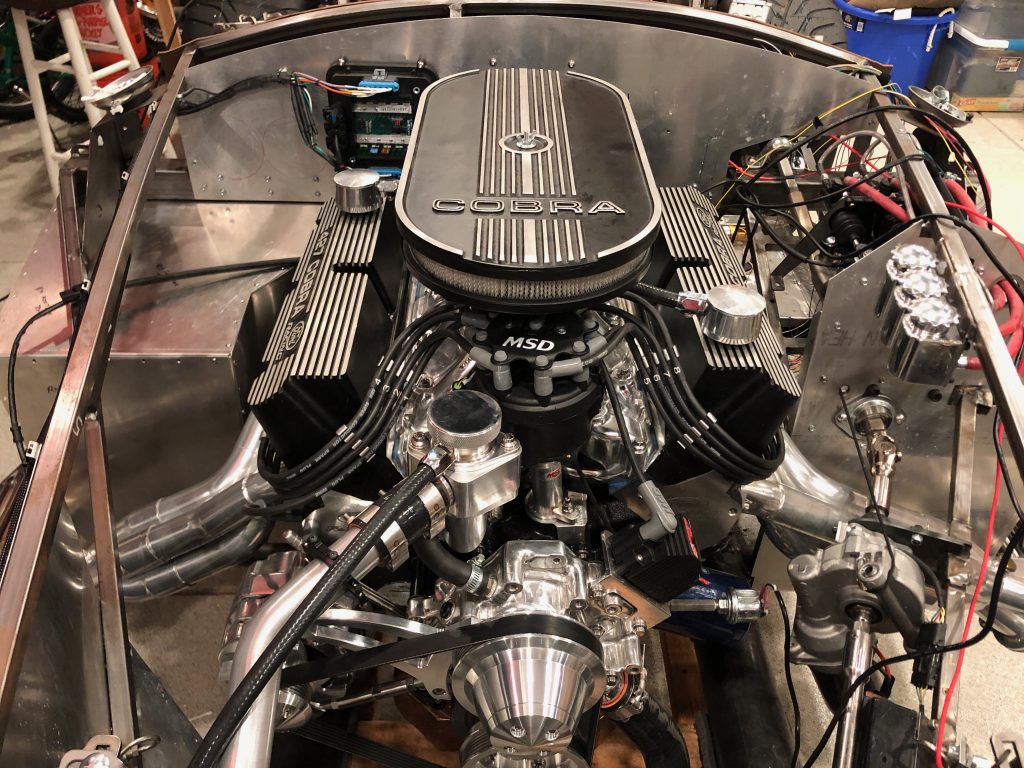

Finished Engine Reassembly

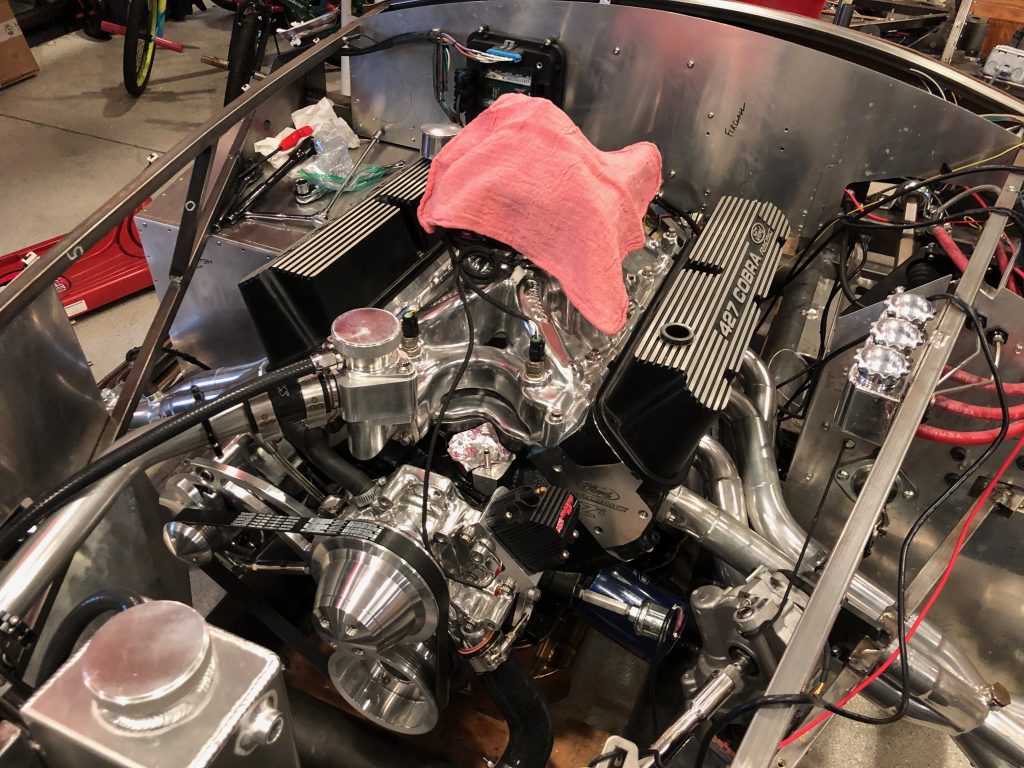

Reassembled Engine (Again)

My dad stopped by tonight and helped me reassemble the engine again. We cleaned up the heads and reinstalled them with new gaskets, then dropped in the new Morel lifters. Fortunately, the new lifters were exactly the same height as the old lifters, so we could reuse the existing pushrods. While installing the lifters, we did take the opportunity to adjust a couple of the guide plates to put the rockers in the center of the valve stems.

After setting the preload on all of the lifters, we installed the intake manifold gaskets and the intake manifold. Finally, we reinstalled the exhaust headers and side pipes since that’s much easier to do with two people.

I still need to stab the distributor, hook up the electrical connections, install the air filter and fill the system with coolant before I can run the engine, but hopefully that will be pretty quick and we can run it tomorrow.

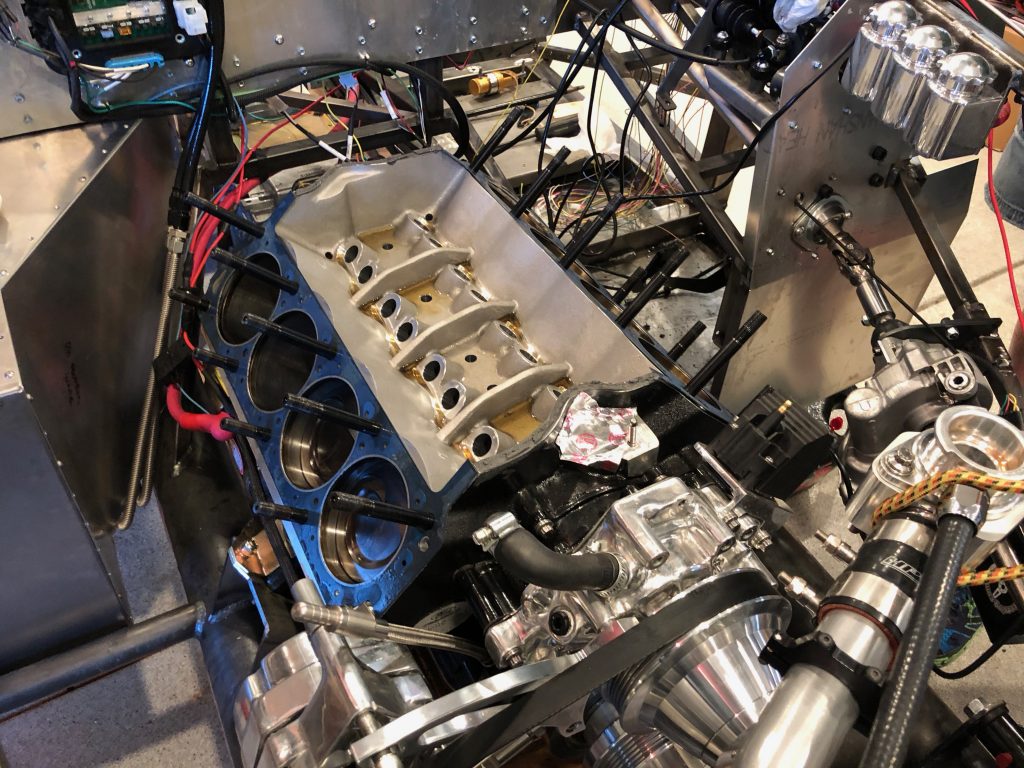

Head Work

My dad picked up the lifters from Dino today. Not too surprisingly, Dino did find a tiny amount of damage to the valves in cylinder #5 (where the nut spent most of the time). The valves were bent about 1-2 thousandths, probably caused by the nut getting pinched between the top of the piston and the partially open valve. Dino reground the valves so that they will seat properly in the head.