I haven’t posted an update in awhile because my dad and I have been diagnosing some noise in the valvetrain. It’s possible that it’s been there all along and that we only noticed it after installing the mufflers, but we don’t really know. The noise sounded like only 1-2 lifters were making noise, but I couldn’t determine which one with as engine stethoscope. The guidance we originally got from Crane was to set a pre-load of 0.060″-0.090″, so we set it right in the middle at 0.075″. This seemed high based on what we were seeing online, so we reset it to about 0.040″ and tried running the engine again. Unfortunately, the noise got louder. We then tried going to the high end of the range at 0.090″, but the engine wouldn’t run smoothly with that much preload.

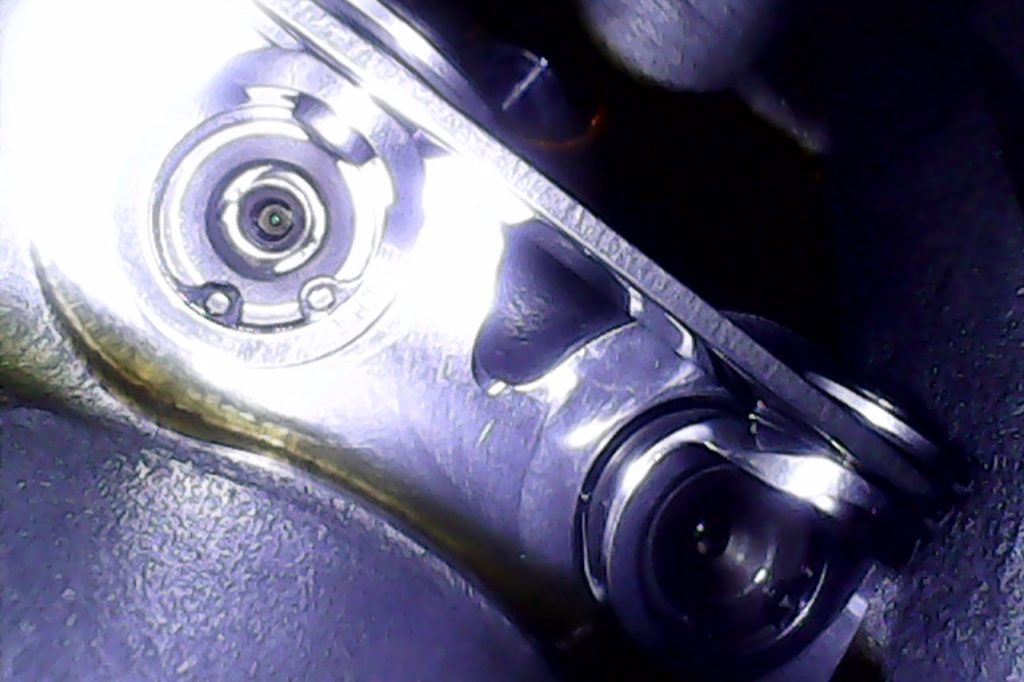

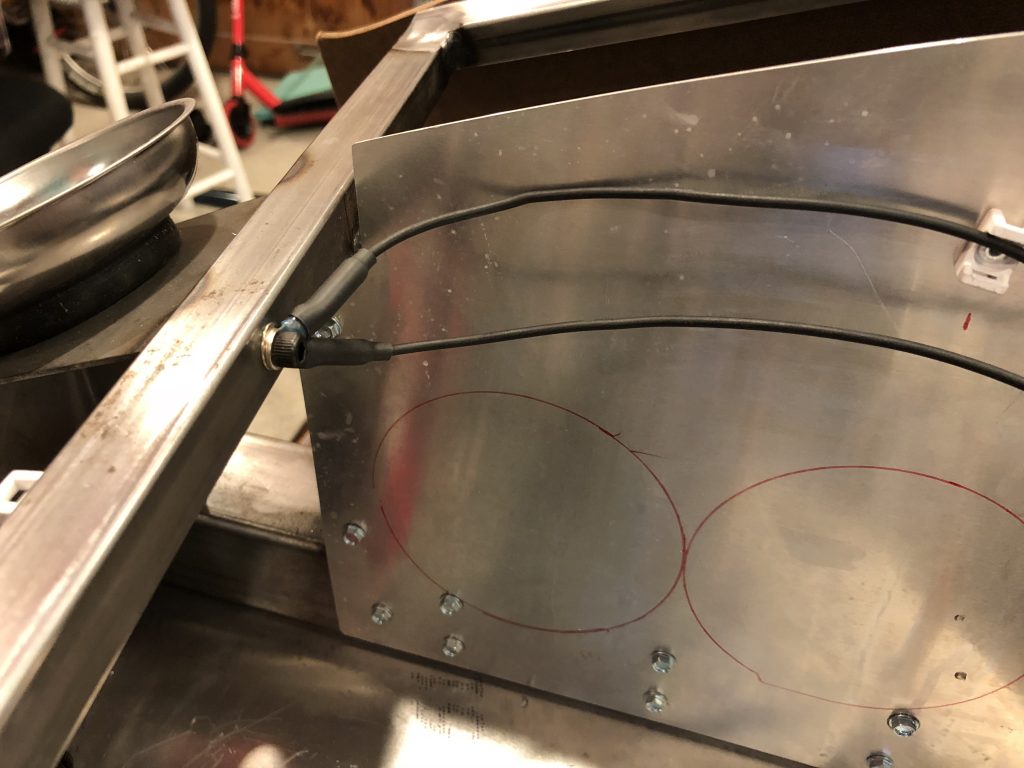

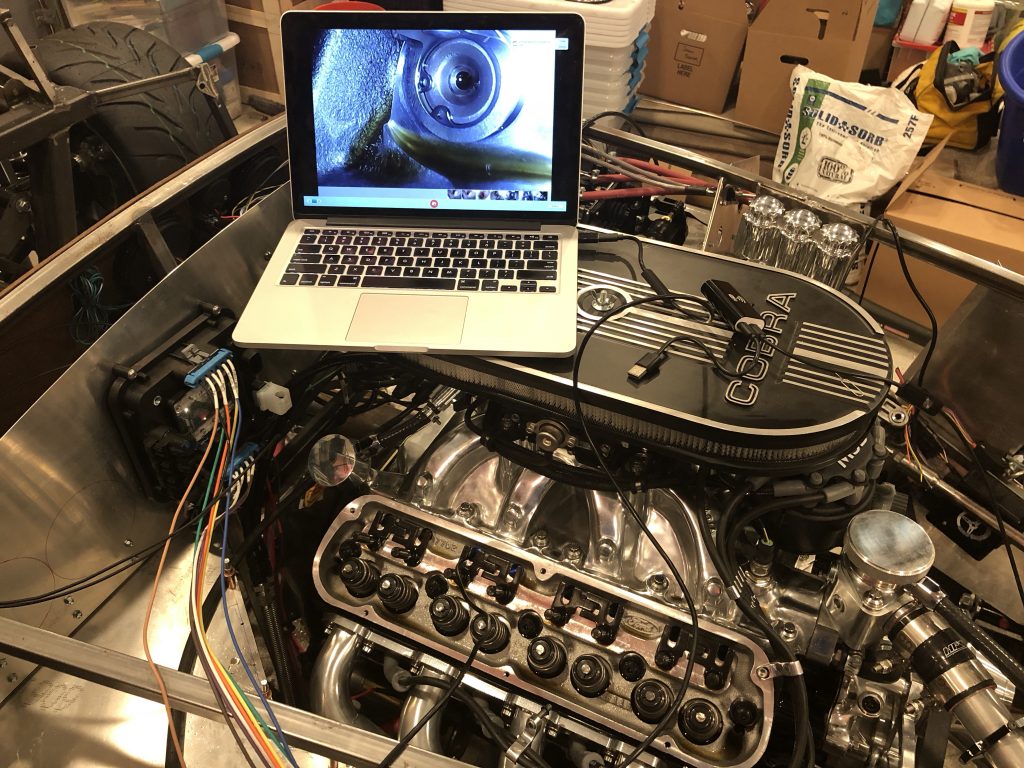

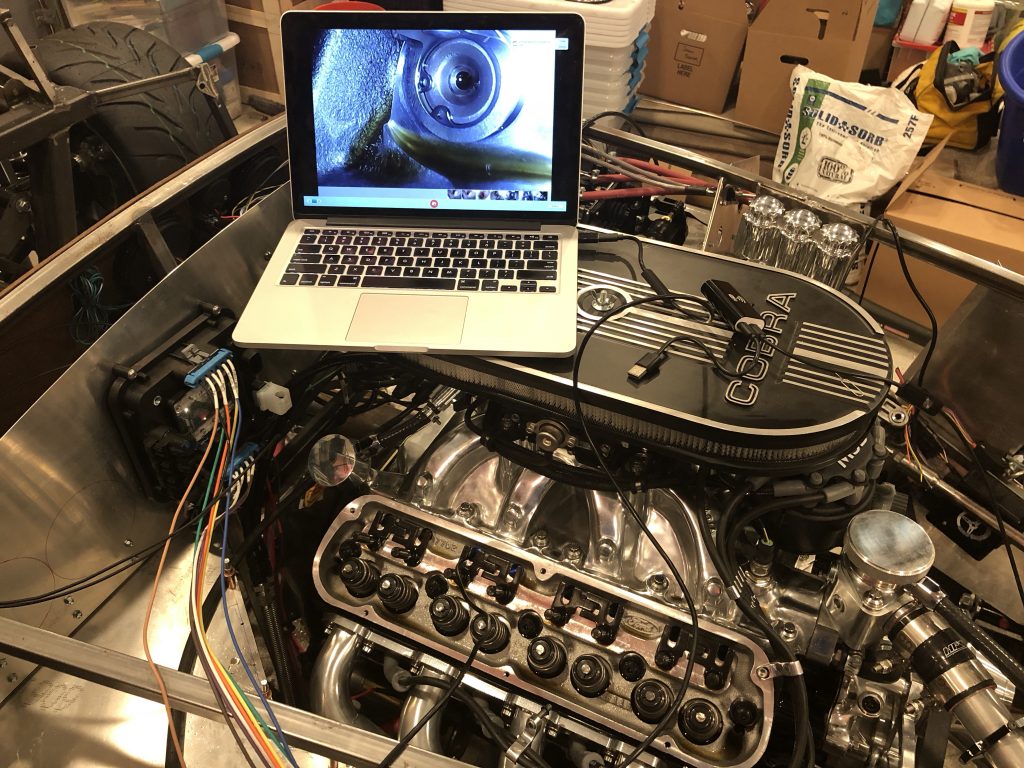

We began to be concerned that the process we were following wasn’t resulting in consistent preload on the lifters. If any of the pistons were partially depressed, we could have significant variation in preload across the lifters. I pulled the valve train back apart again and used an 8.0mm USB inspection camera to inspect all of the lifters. This was only about $20 on Amazon and has a surprisingly good picture for the money.

The tip has 8 LED lights that can be dimmed. The 3M long cable is flexible but will hold its shape when bent.

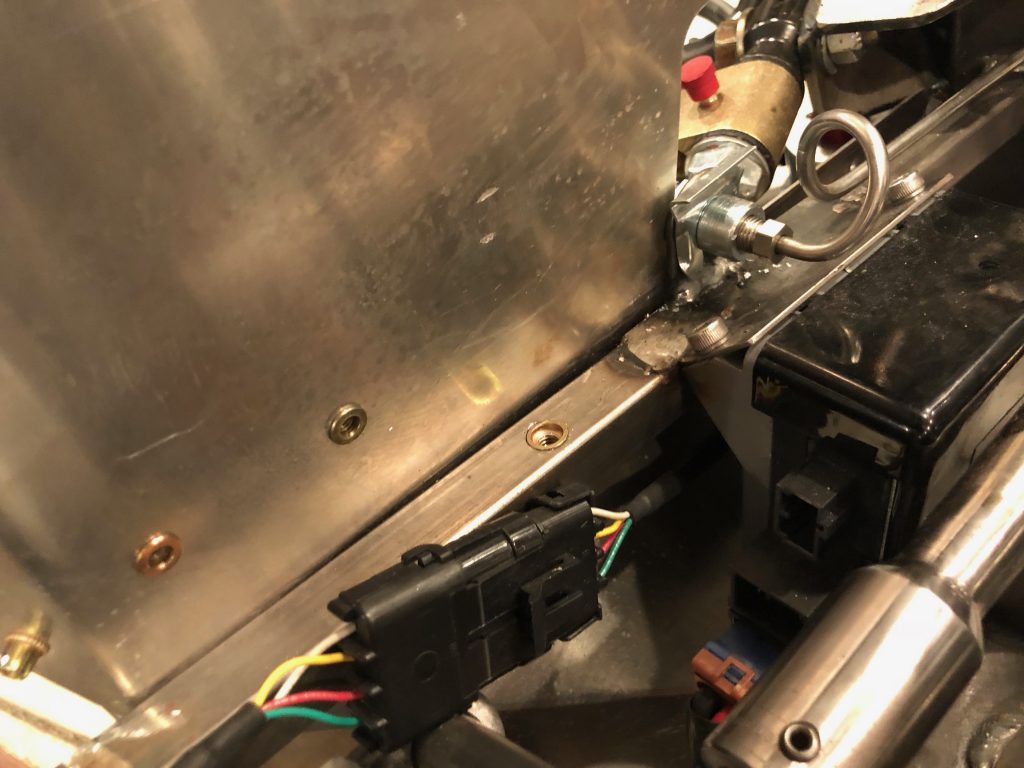

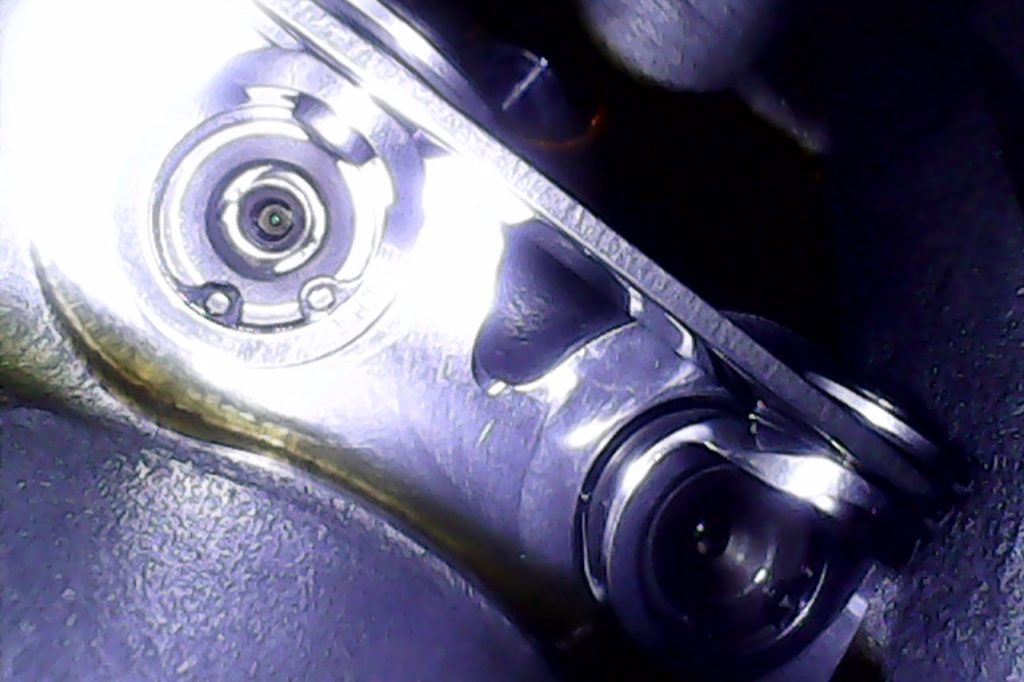

That feature turned out to be handy because I was able to put a curve in the cable and go down through the intake pushrod hole to inspect the exhaust lifter (and vice-versa). This let me look at the lifters at an angle instead of straight on which helped make it more visible that the lifter pistons were at the top of their bores.

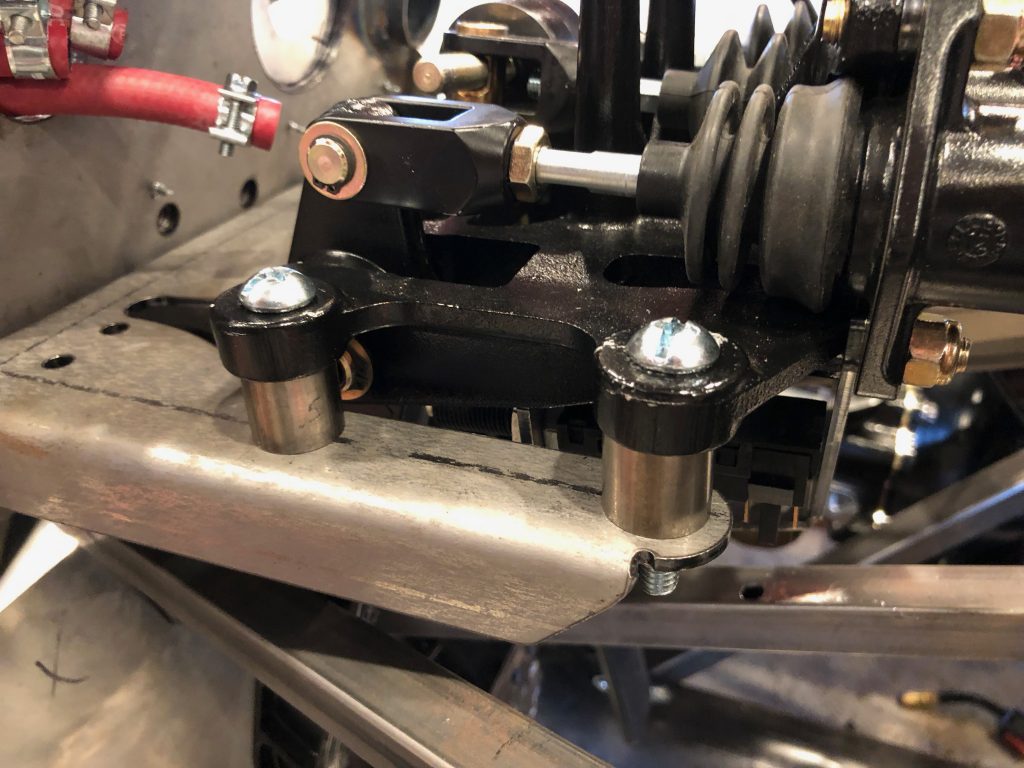

I was also able to pull back a bit and inspect the link bars. Everything looks good, but there may still be a problem that is internal to the lifters (e.g. bad or clogged check valve) that could be causing the problem.