The installer came out and finished up the new side garage door opener. Despite my request to watch the new paint, he managed to get his grubby hands all over the walls and ceiling, so I’ll have to clean and probably touch up the paint.

We tried a couple of times to fish a wire down the wall to the outlet behind the lift, but since this is an outside wall, I can’t get close enough to the top of the wall to make it work. We ended up installing a new 20A circuit in the ceiling and running it back to the subpanel.

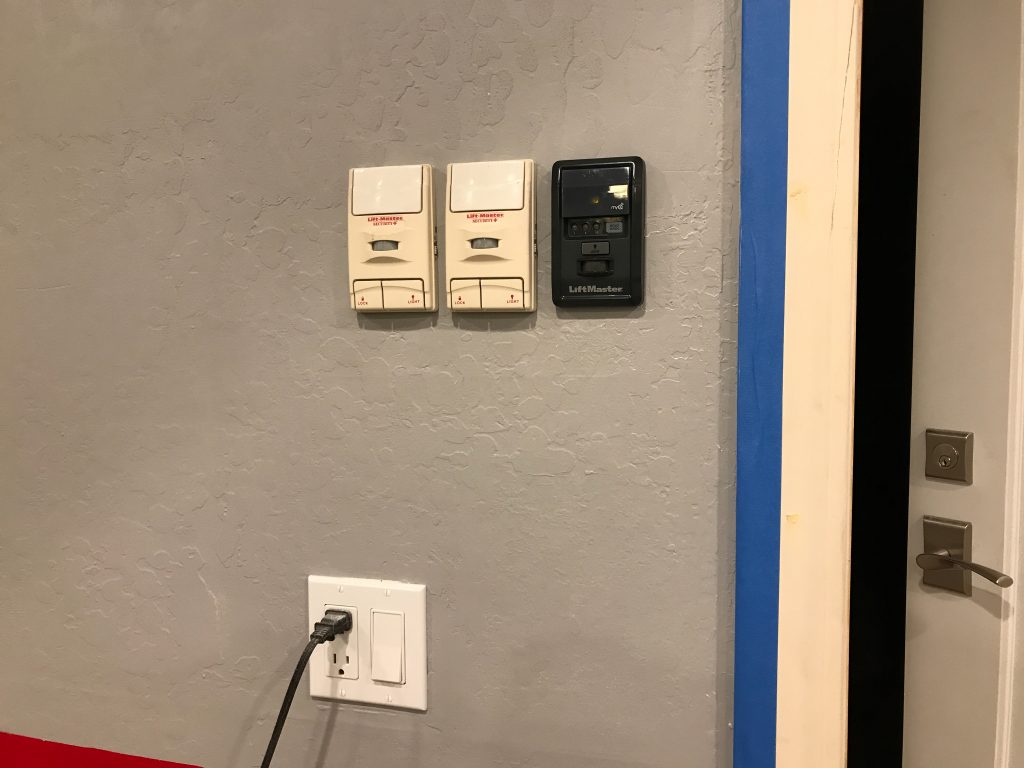

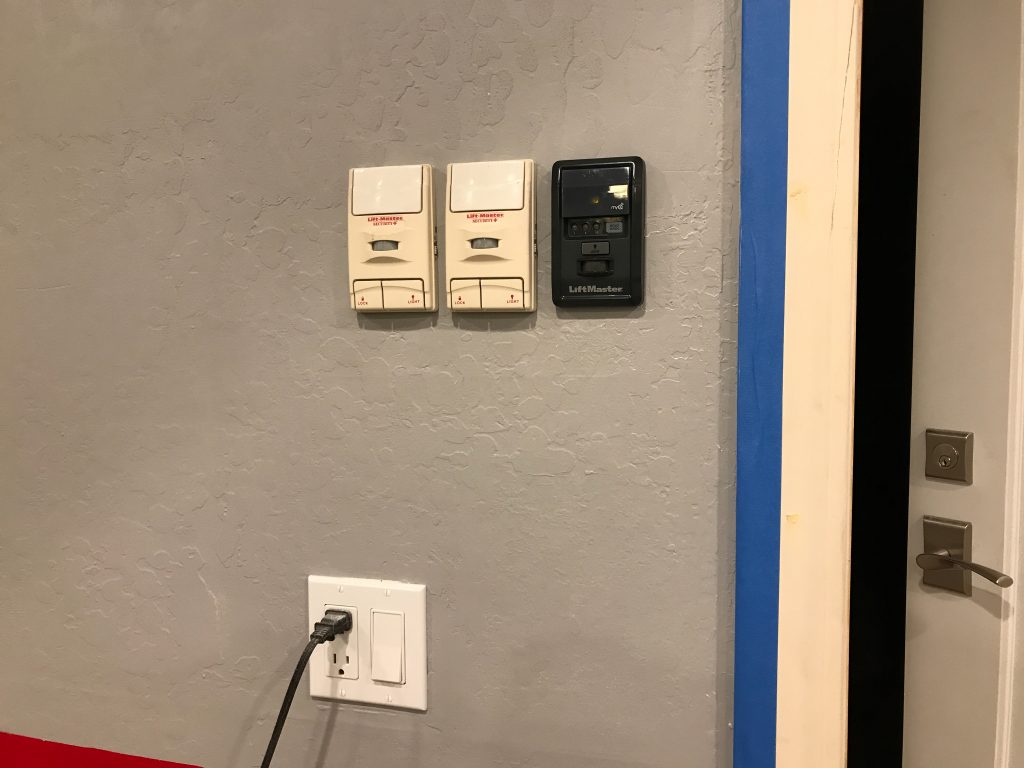

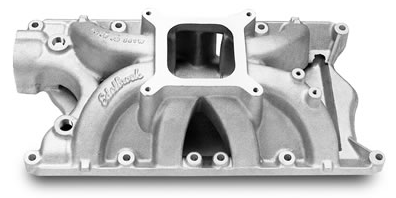

I also added a new 20A circuit in the wall and ran this back to the subpanel so I have a dedicated 20A circuit with nothing else on it. I picked up a Hobart 140 welder to use on the project, and it needs a dedicated circuit to avoid blowing the breaker.

I also jumpered from the switch up to the horizontal outlet at the top. The undercabinet lights will plug in here so that they can be controlled by the switch.

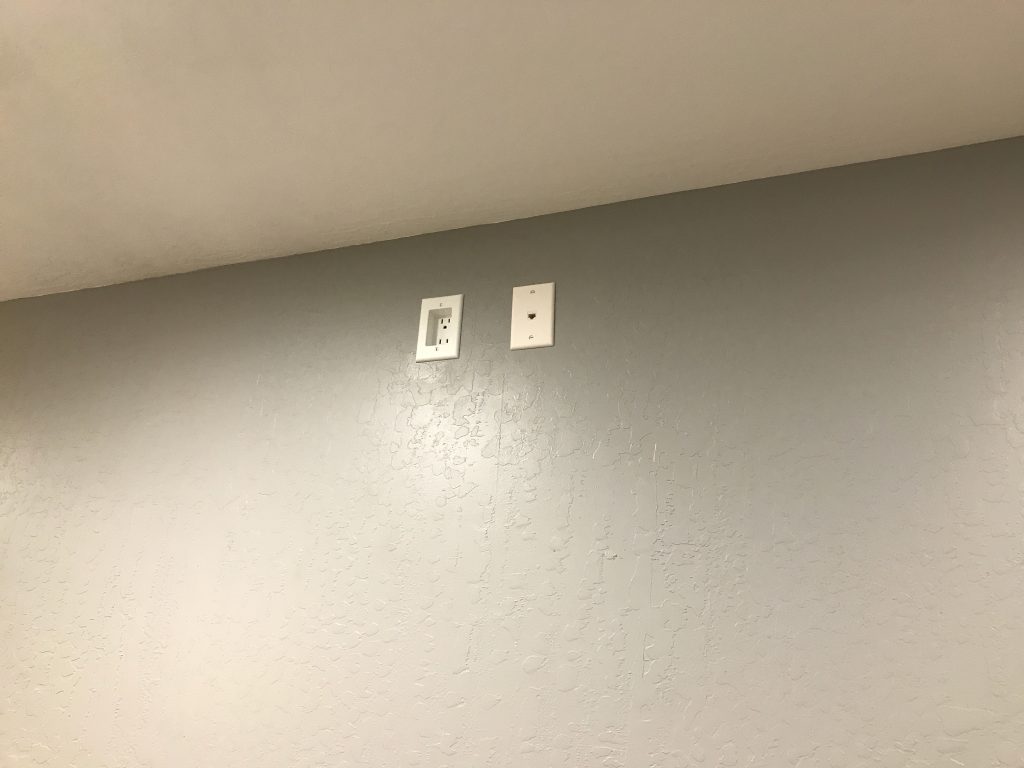

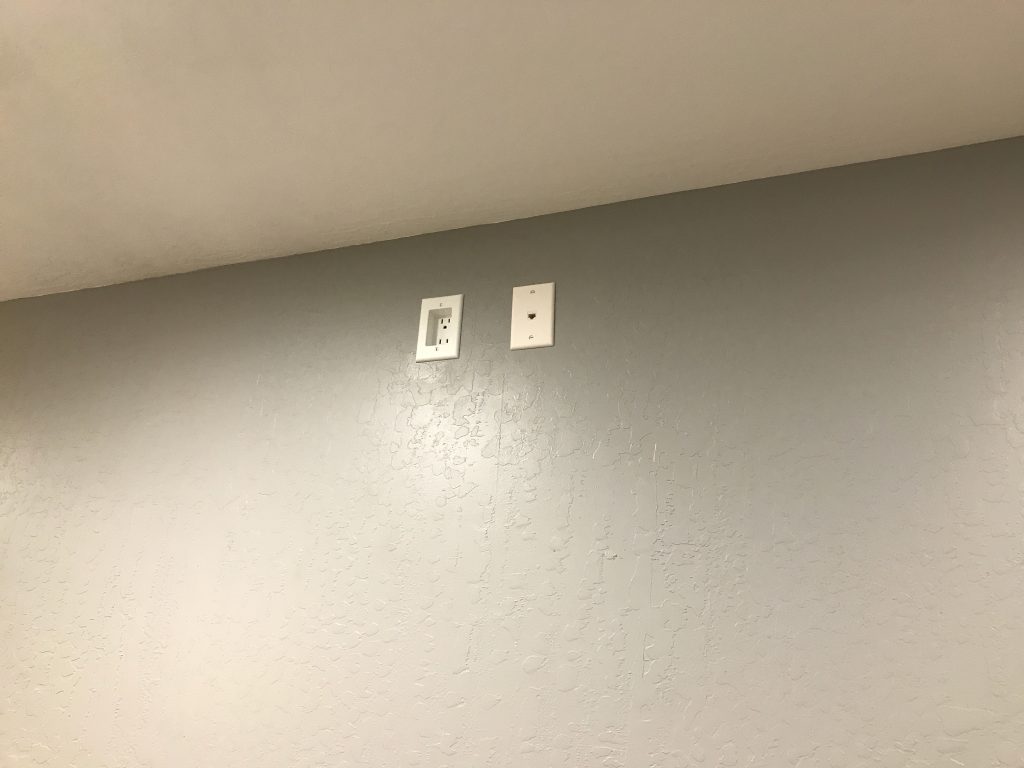

I also added a new outlet and ethernet jack at the top of one of the walls for the TV that will be installed here. My dad gave me an old flat panel TV he no longer needs that we’ll use until we upgrade one of the TVs in the house.

The old wall controls for the garage doors had the wires just stapled to the drywall. They ran up the wall and then rather haphazardly across the ceiling to the openers. Since we’re trying to make the garage look pretty nice, I decided to run the control wires through the attic. The installation looks so much cleaner this way.