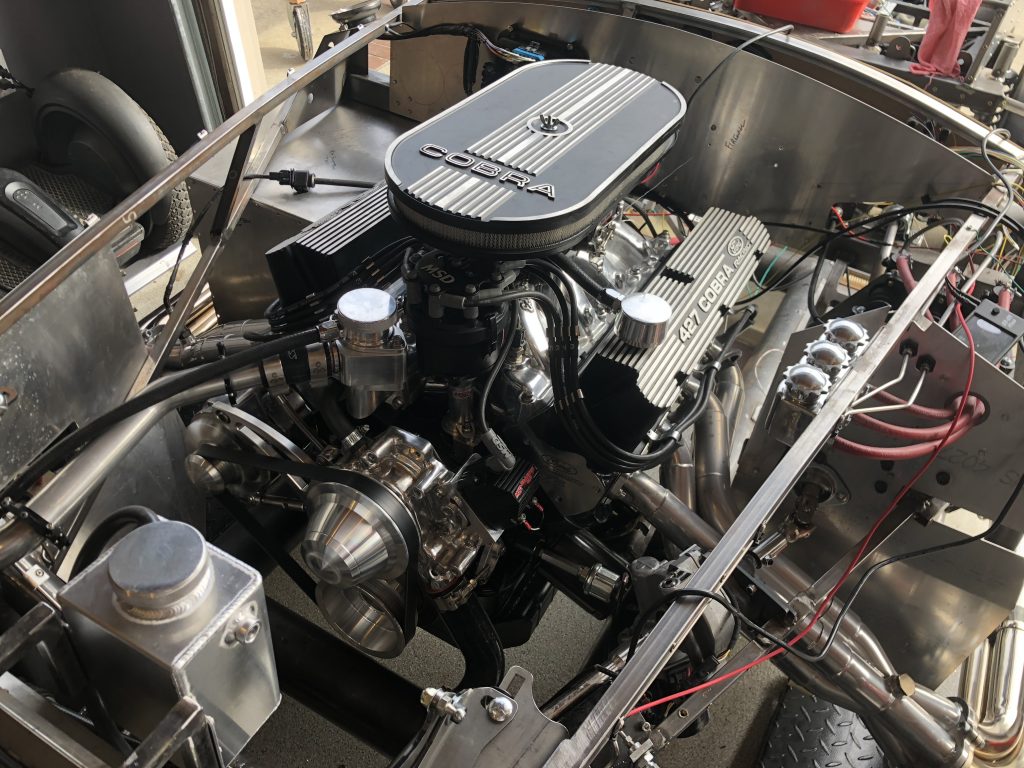

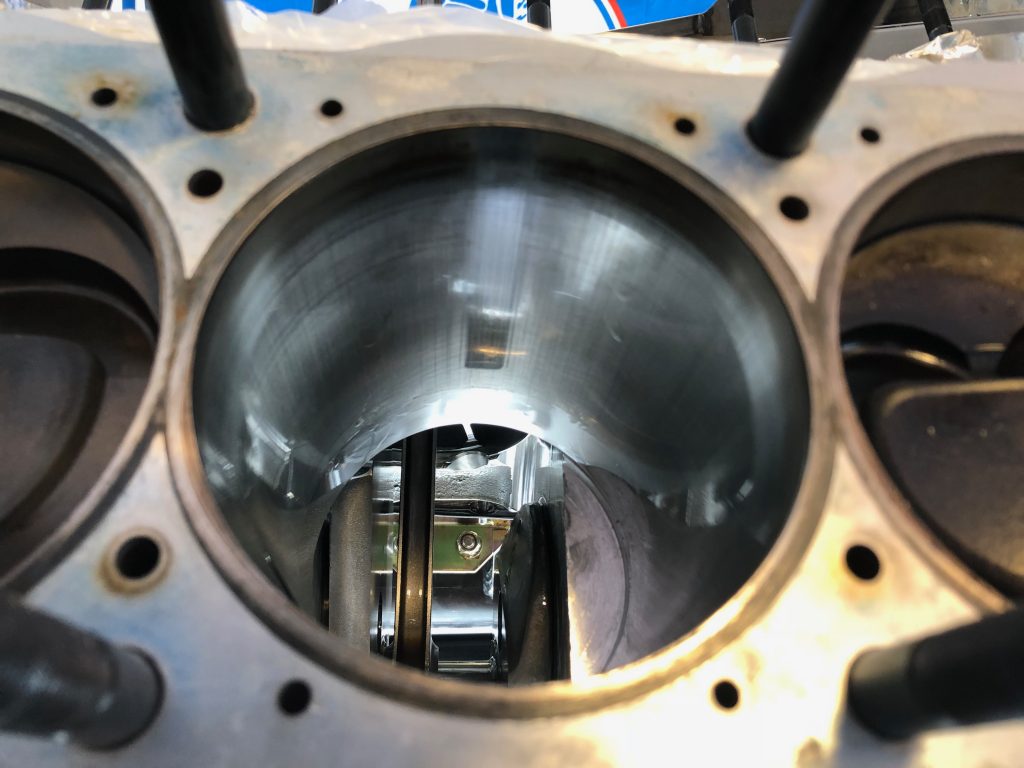

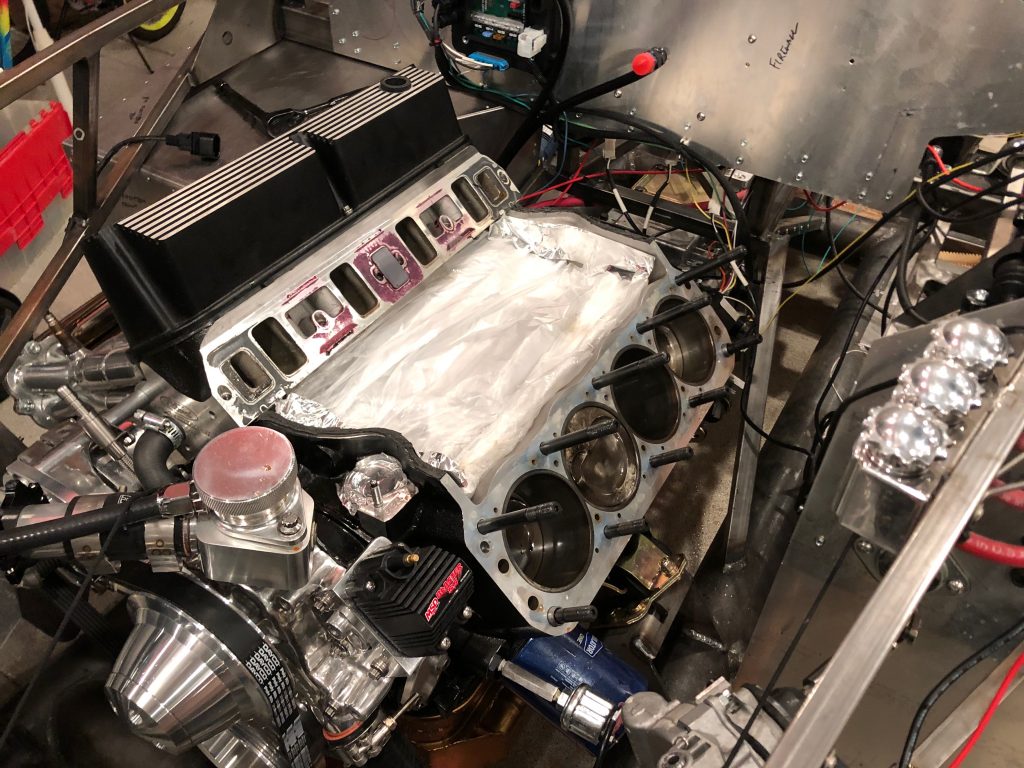

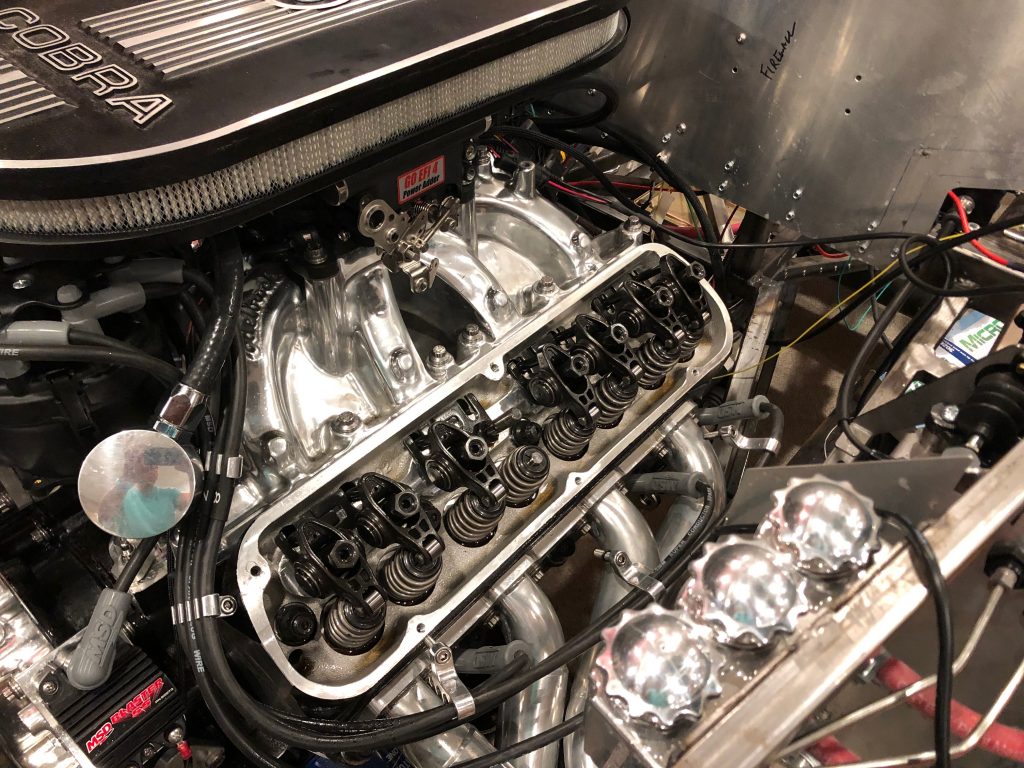

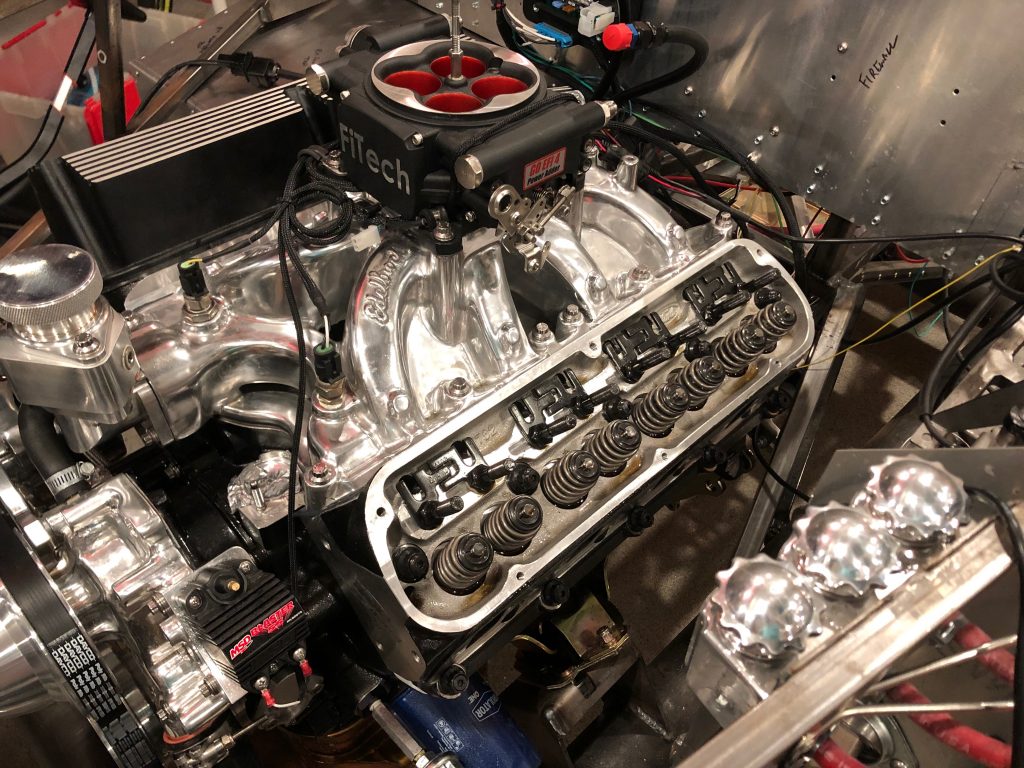

My dad stopped by again this morning and we wrapped up the engine assembly. We ran the oil pump for about three minutes with a drill and spun the motor over a few times with the starter (without plugs) to make sure oil was nicely distributed throughout the engine.

The moment of truth arrived and we fired up the motor. Success!!! The motor sounds fantastic. Nice and smooth, and no knocking!

We kept the exhaust pipes outside of the garage to limit the exhaust inside. We pushed the RPM up to about 2,500 and let it run for about 30 minutes to help seat the rings.

After shutting down, we pulled the car back into the garage and put the car back on the dolly. Since we’re still in the middle of our remodel, we likely won’t make much progress on the car over the next few months, but I’m incredibly pleased that this is behind us!