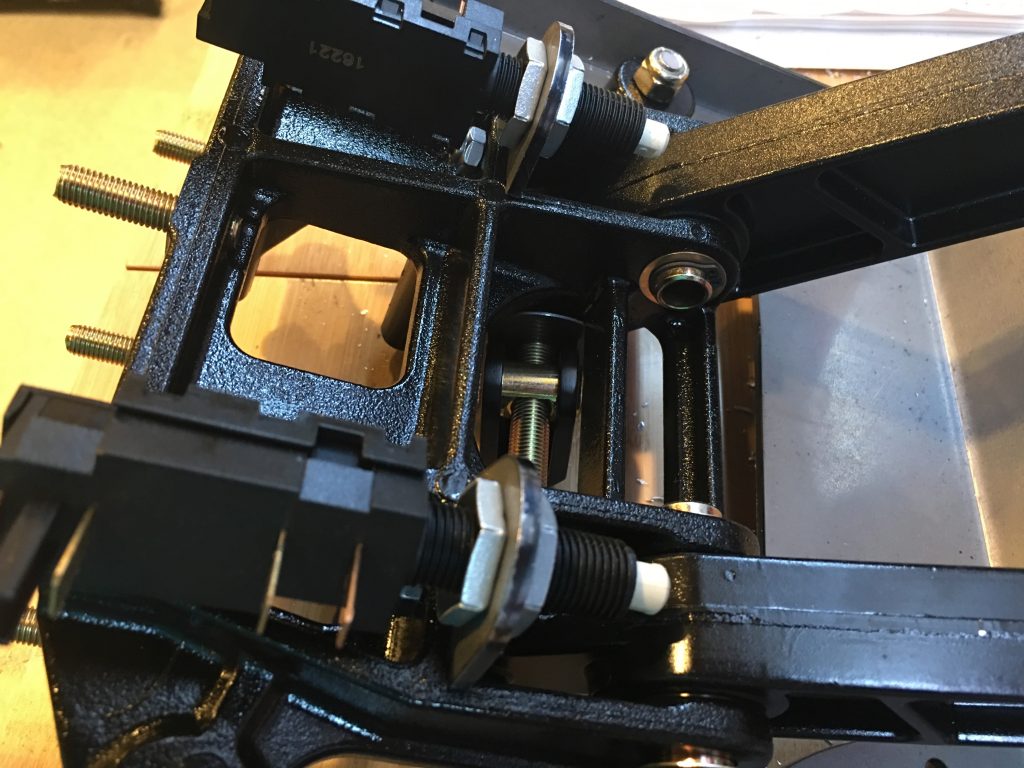

We got back from AirVenture yesterday and our new shocks had arrived along with the extended eyelets. The eyelets just unscrew from the shock shafts and the new ones thread on.

I really like how the QA1 shocks have easily serviceable components. The bearings in the eyelets are held in with snap rings, so they can easily be moved from the old eyelets to the new ones. If they ever need to be replaced in the future, it can be done without replacing the entire shock.

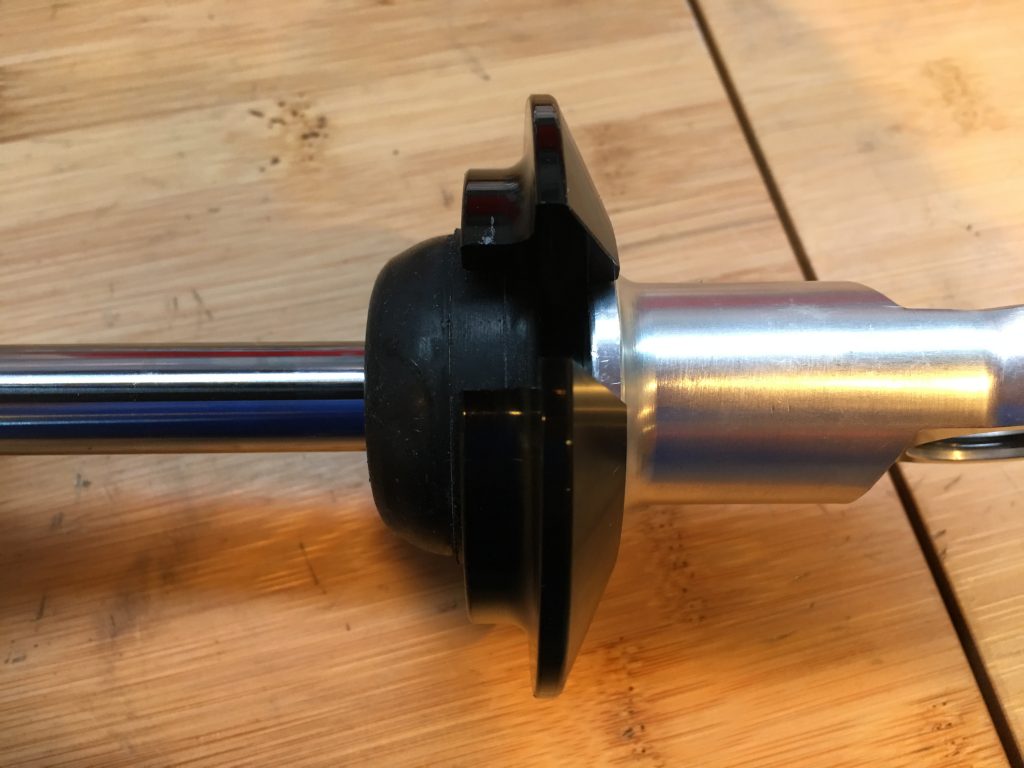

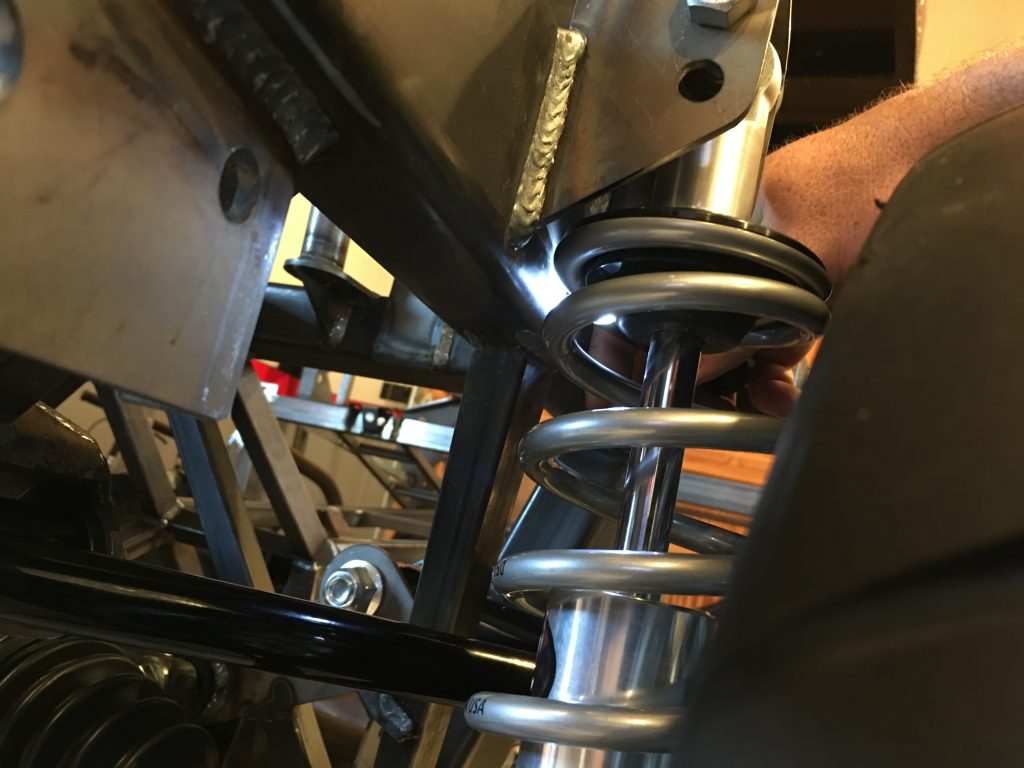

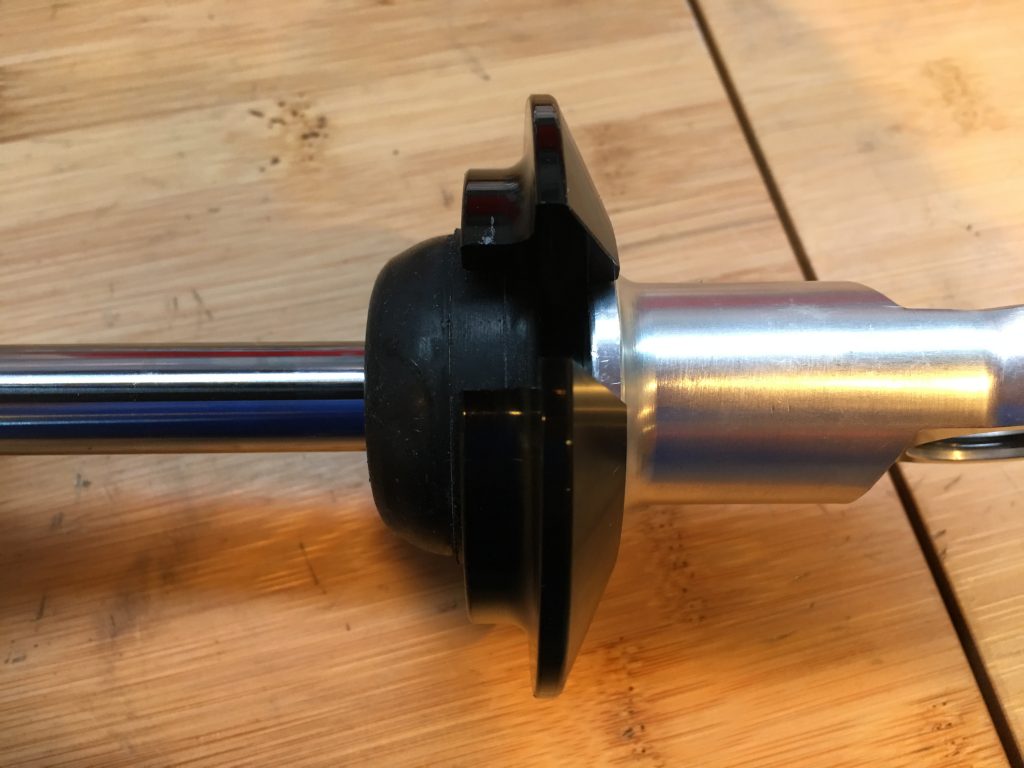

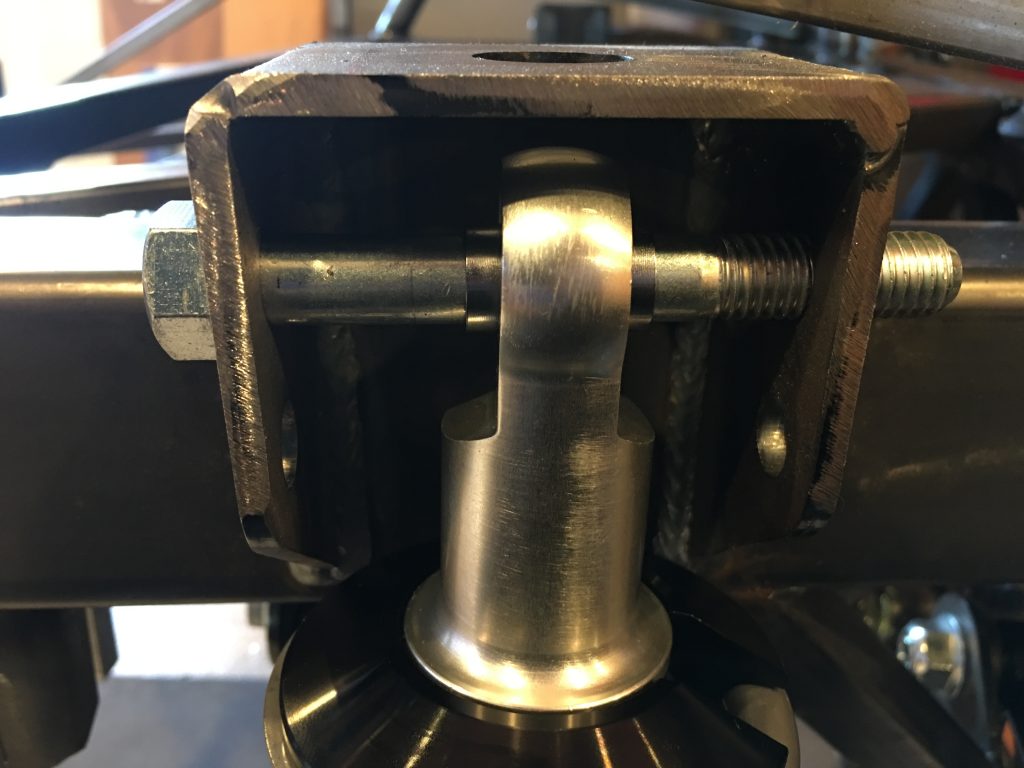

Since I had the eyelets off, I installed the bump stops onto the shafts.

I couldn’t find any instructions that indicate which direction these should face, but they seemed to fit in the upper spring seat better in this orientation.

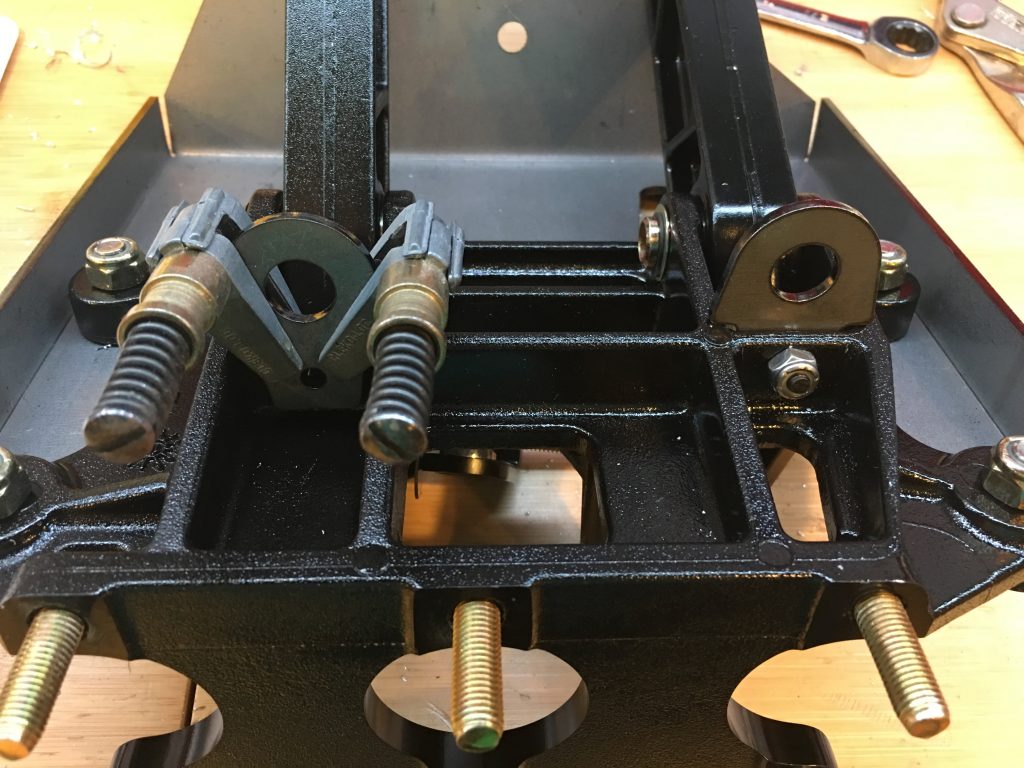

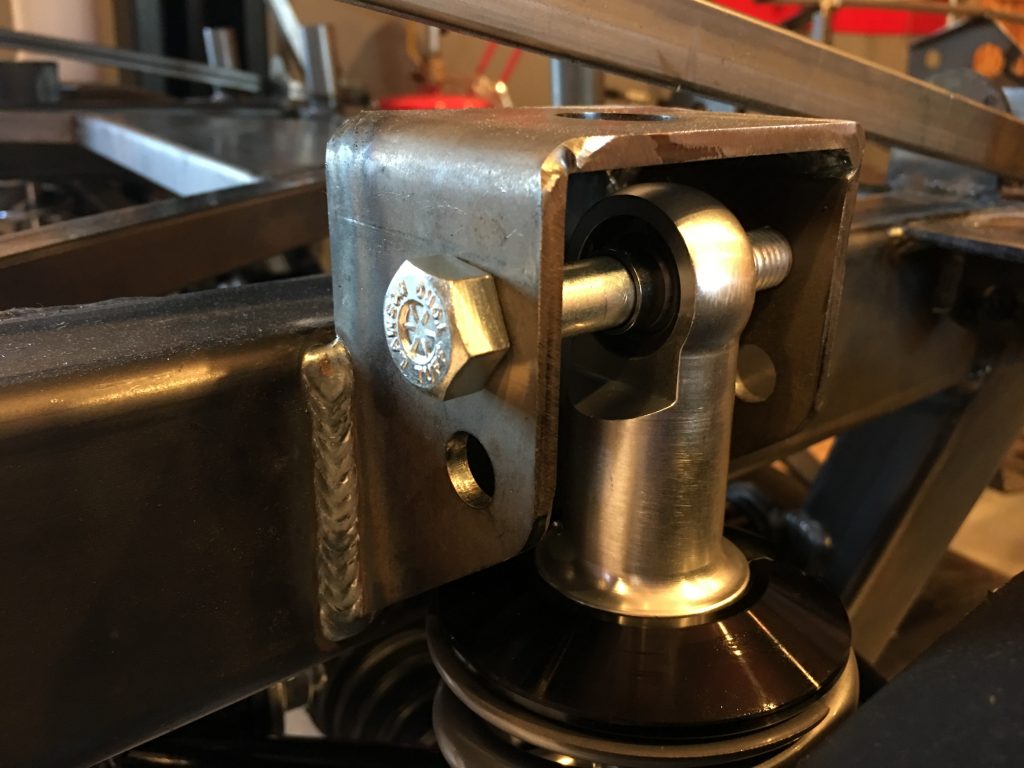

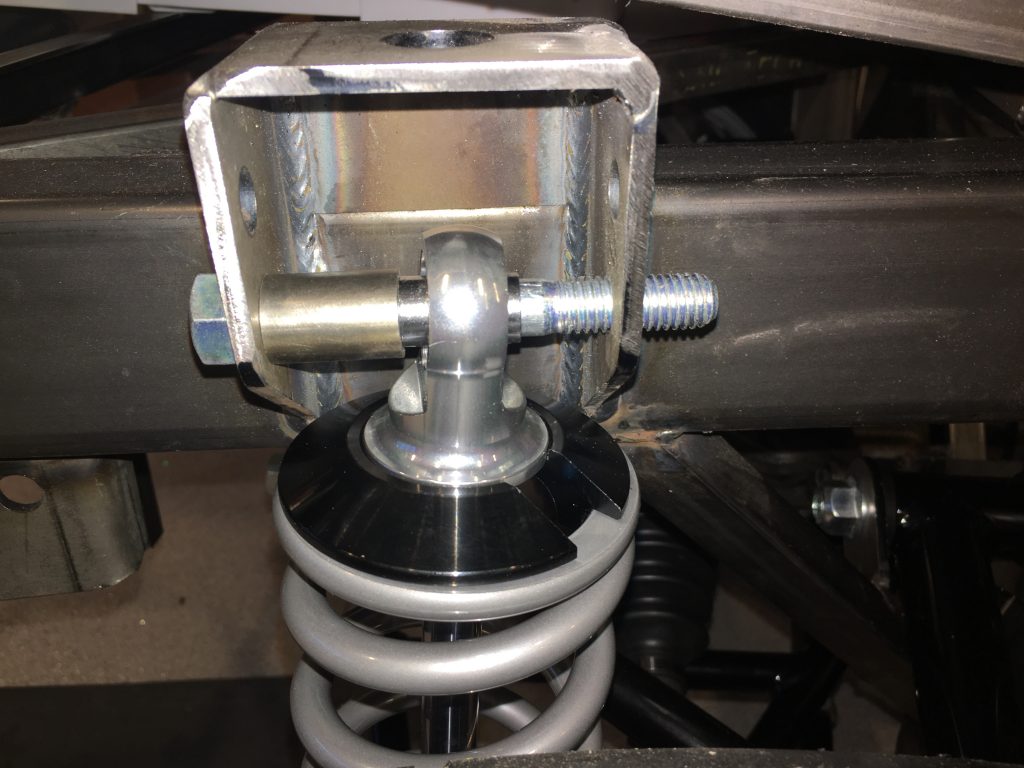

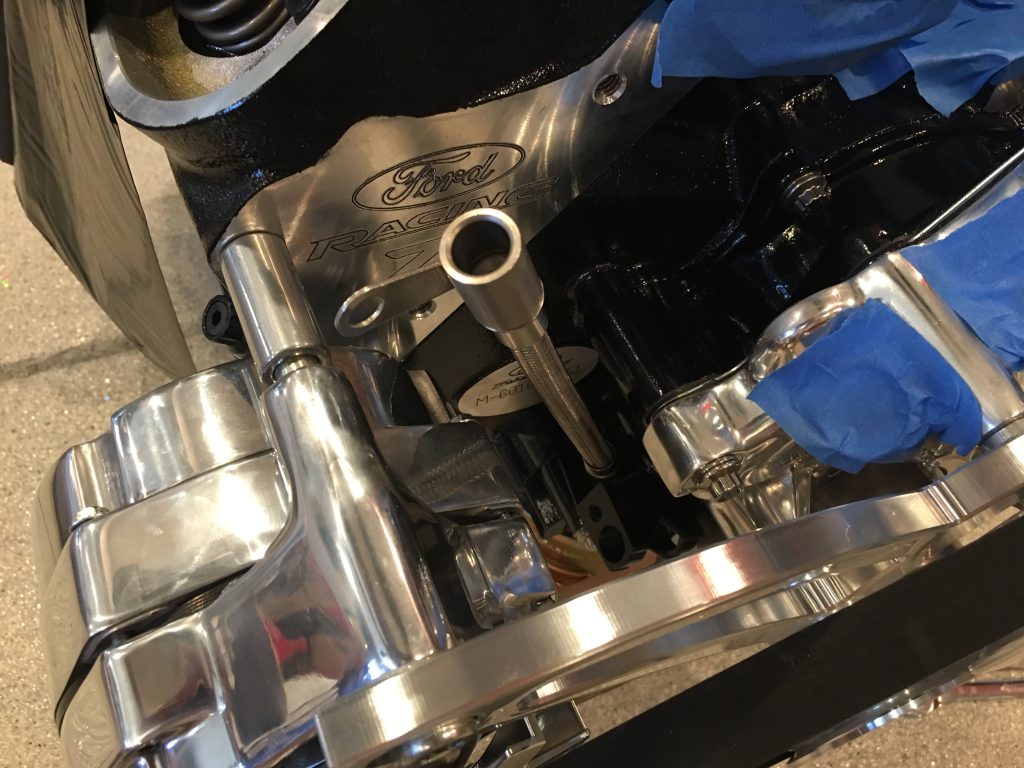

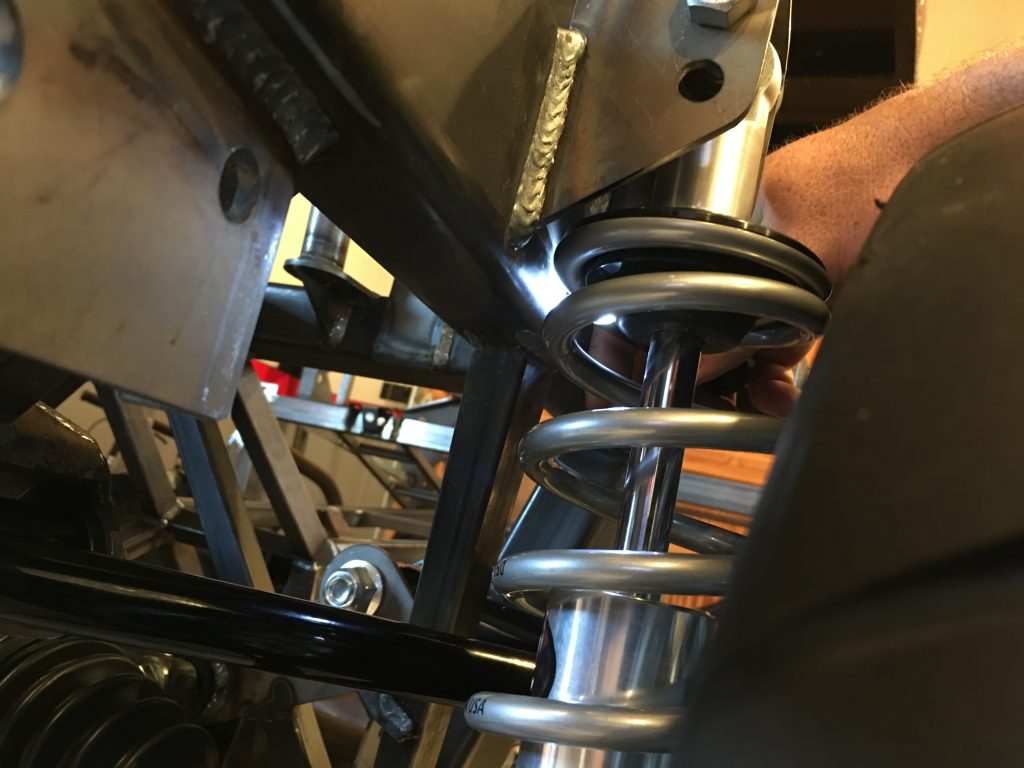

With the extended eyelets installed, I could mount these in the upper mounting hole.

I still need to mount the upper end of the shock slightly off center to have the spring seat be centered in the bracket.

The upper mounting hole pushes the shock slightly outboard, so the spring now clears the rectangular tubing. Other than fine tuning the spring rates, I think these shocks will work great now. With everything test fit, I measured for all of the spacers. Unfortunately, the spacers they shipped in the kit aren’t sufficient for fabricating all of the ones I need. I ordered some tubing from McMaster-Carr and will fabricate those soon.

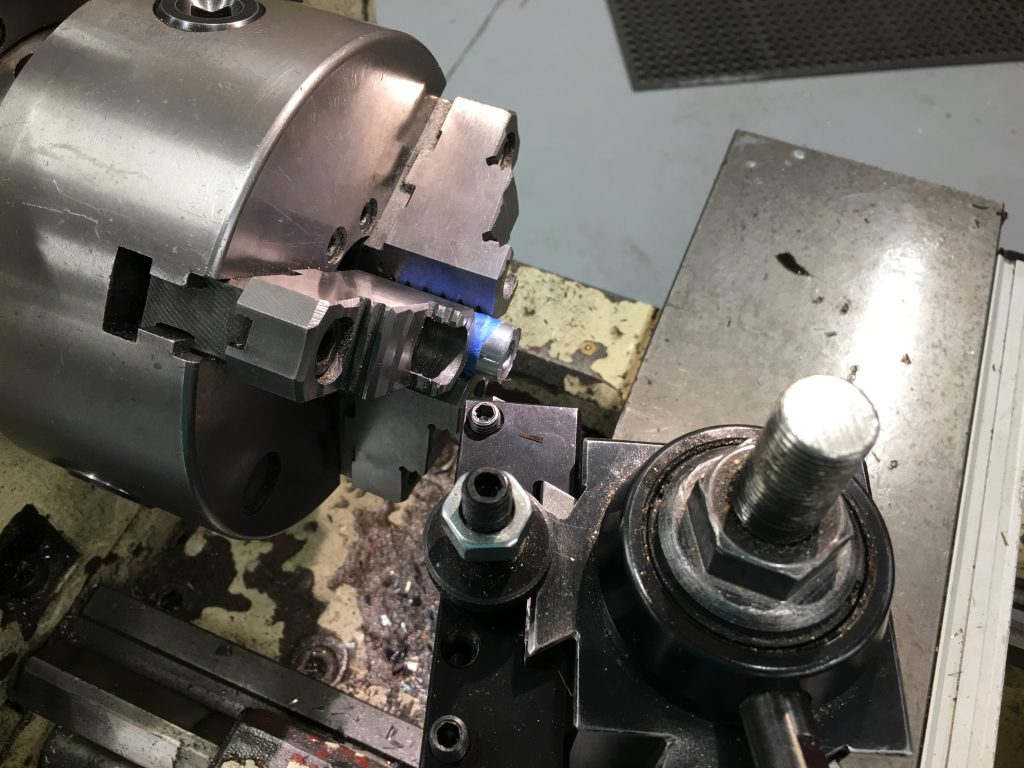

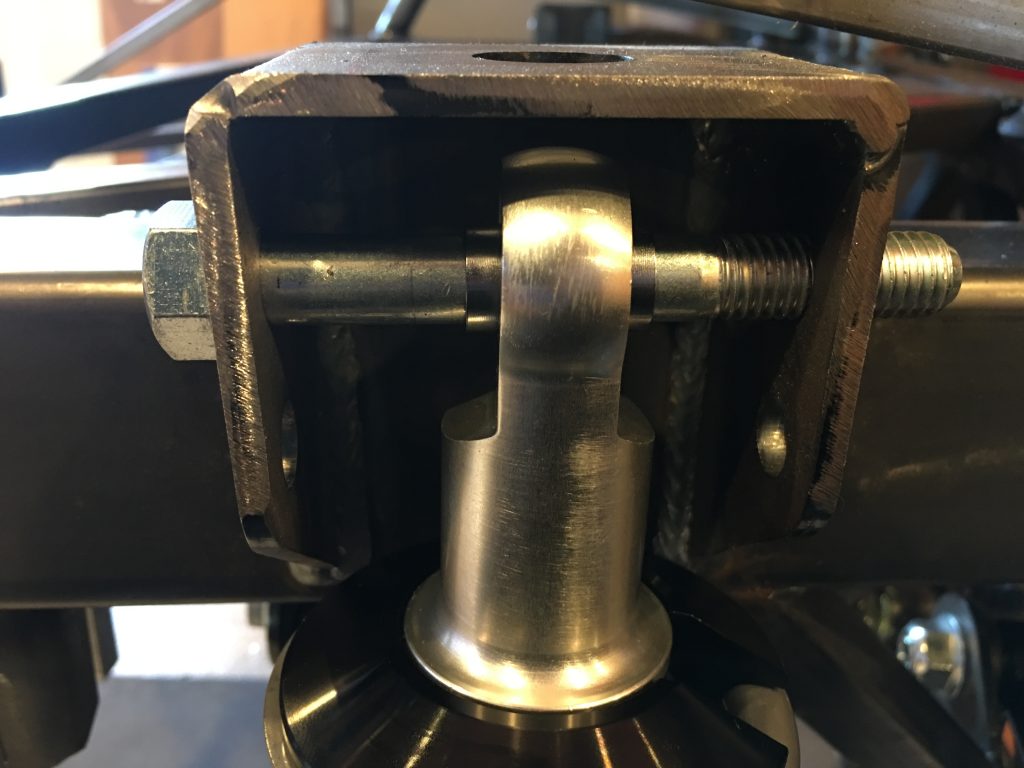

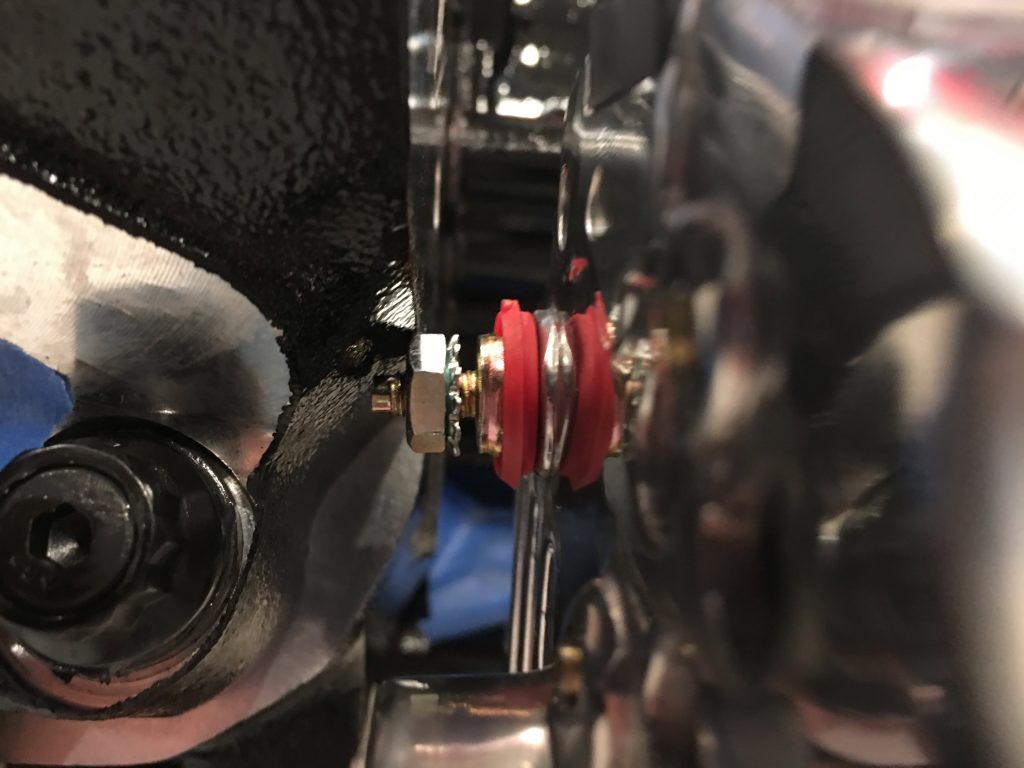

With the shocks installed, I started working on the sway bars. The rod end bearings are too long and need to be cut down until only 1/2″ of threads remain.

After trimming both the male and female rod end bearings for the front sway bars, they’re threaded together until they’re basically bottomed out and the bearings are 90º apart.

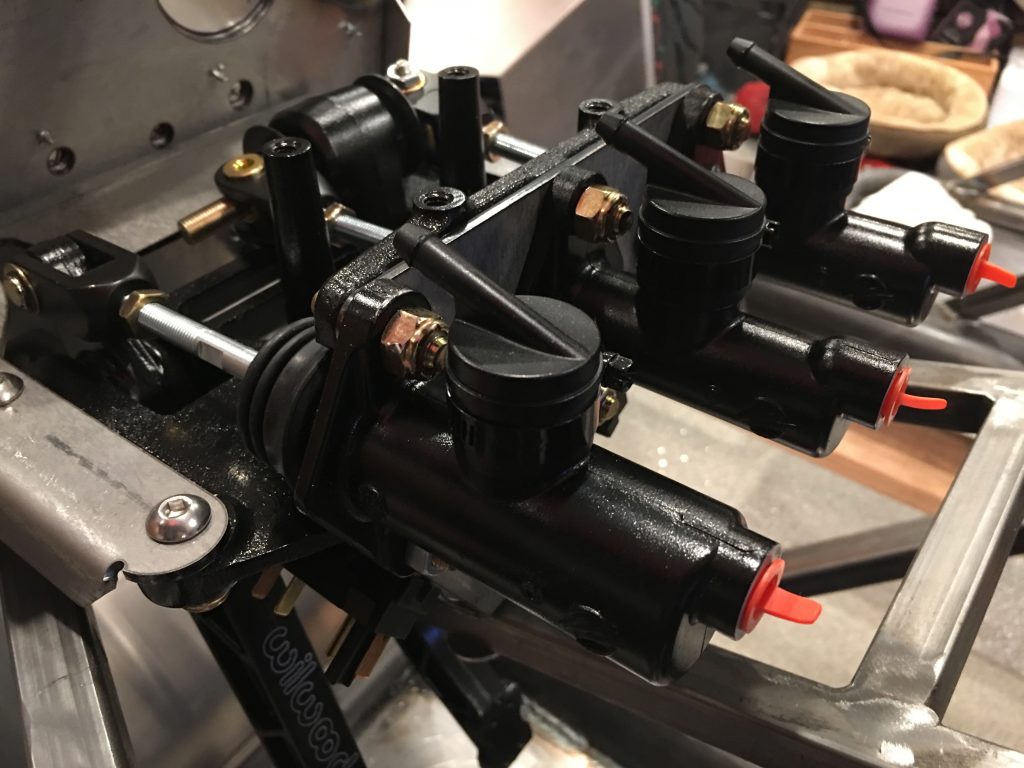

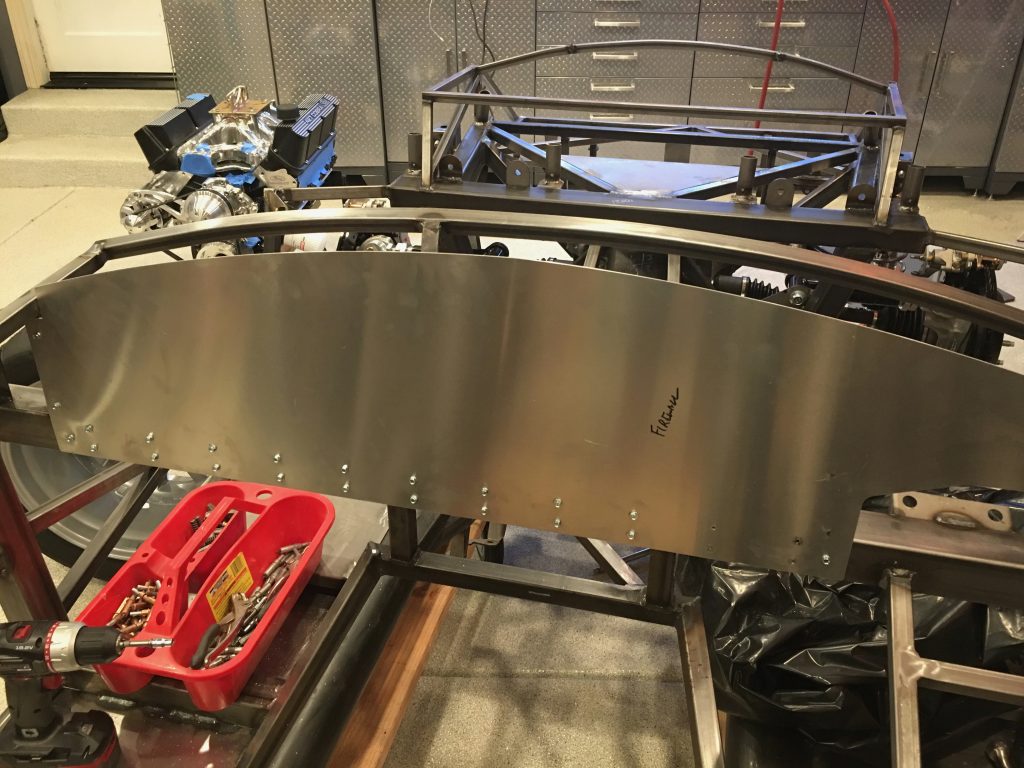

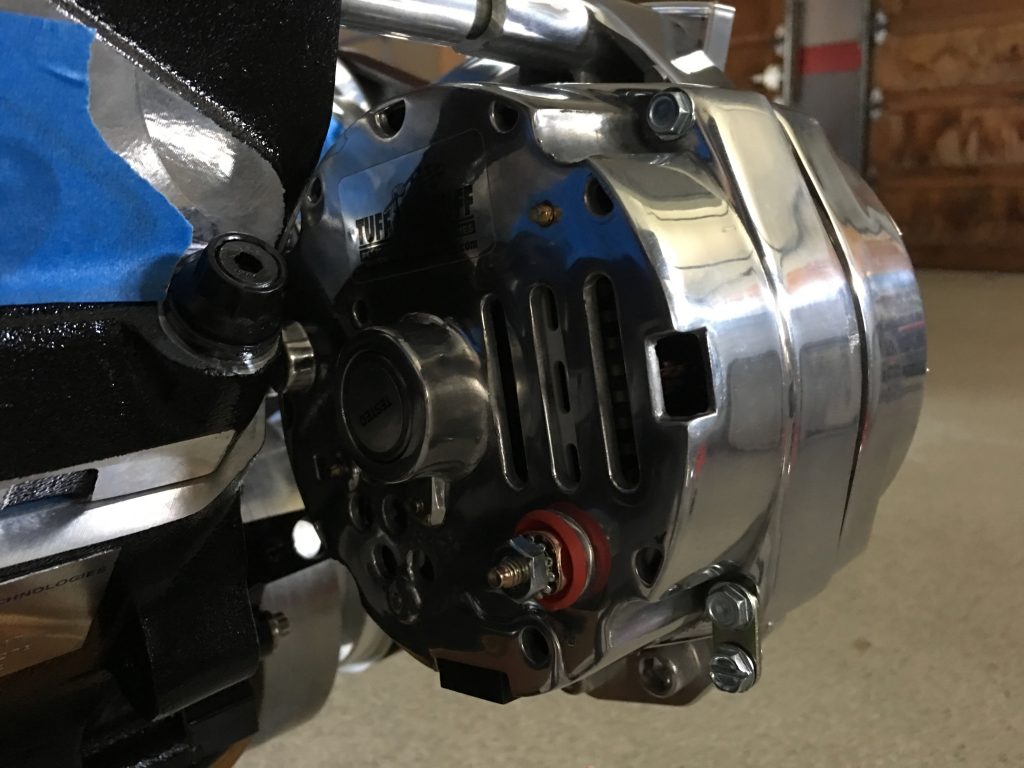

I installed the front sway bar to the mounting bracket.

The ends of the sway bars are attached to the bottom of the shock mounts through the rod end bearings. The spacer seems too long here, but the bottom of the shock moves outboard as the suspension compresses. The rod end bearings should be basically straight up and down when the suspension is at ride height.

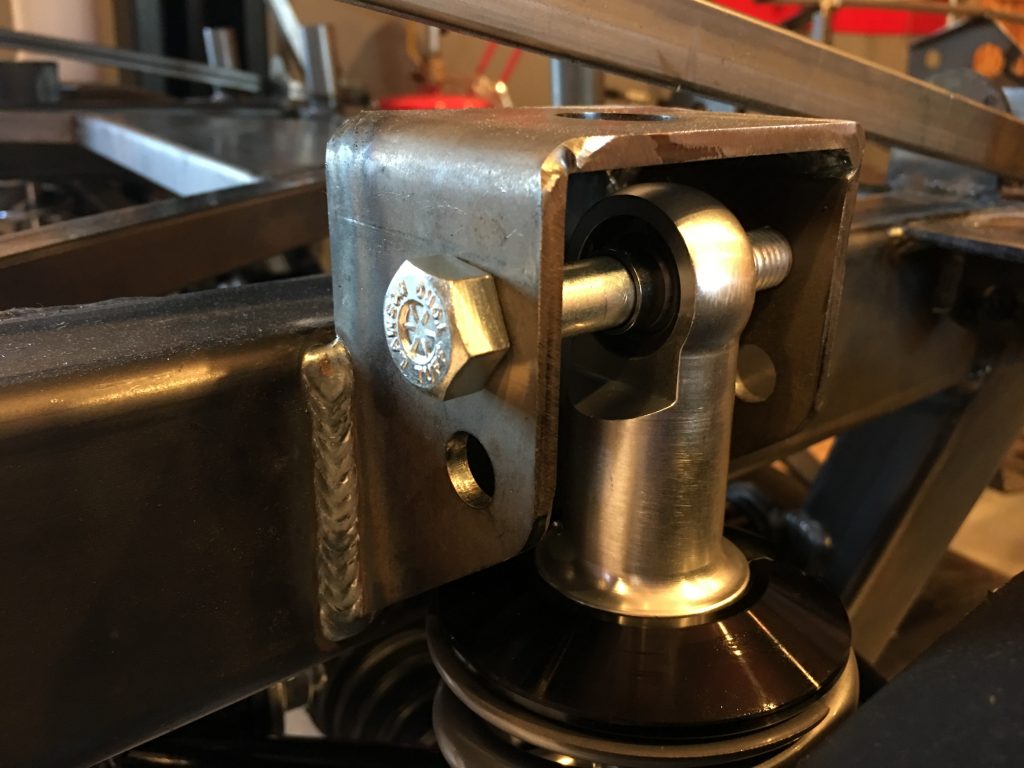

The rear sway bar mounts to a pair of brackets that are bolted to the chassis using the same bolts that hold the toe arms and the forward end of the lower control arms. I really wish I had realized this when we did the initial assembly of the rear suspension.

Once the bracket is bolted on, the sway bar can be bolted to it.

The other end of the sway bar is bolted to the lower control arm through a pair of rod end bearings. I need to fabricate some spacers to take up the extra space between the mounting ears.