The water pump came with a couple of brass fittings for the heater hoses. We’re trying to keep the engine all black and polished metal though, so I decided to try plating the fittings. I picked up the tin-zinc plating kit from Eastwood a few weeks ago, but haven’t had a chance to try it out.

The kit is pretty easy to use and took only a few minutes per part to plate. As you can see, the parts look much nicer now.

The parts come out of the plating solution like you see on the left. A minute or so with a dab of the metal polish that comes in the kit shines it up nicely.

The valve cover bolts that came with the ARP engine bolt kit weren’t long enough. Apparently they’re intended for use with a stamped valve cover and cork gaskets. We’re using cast valve covers with thicker rubber gaskets, so we needed longer bolts. ARP was nice enough to exchange them for me and they arrived today.

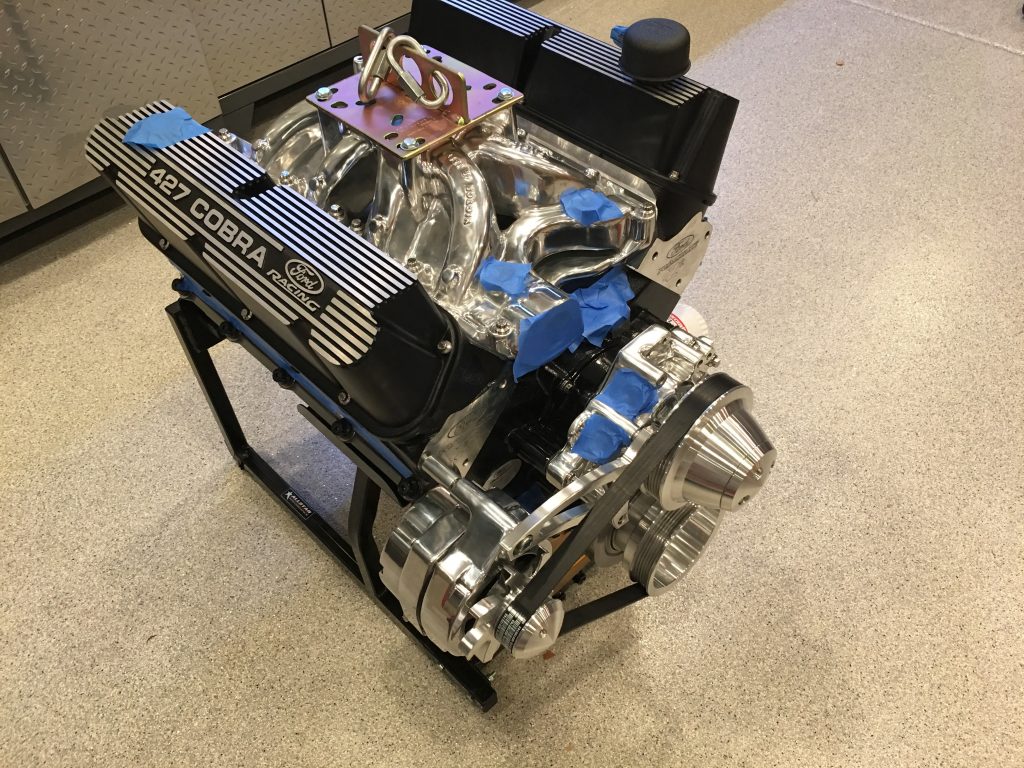

The engine is all sealed up now and looks much better too.

We also got an order from Summit with some 2″ 3/8″-16 bolts, so I swapped out the hardware store bolts for them. We also got a longer spacer from March Performance, but I need to trim it down to the right length.

2 thoughts on “Plated Fittings and Received New Bolts”