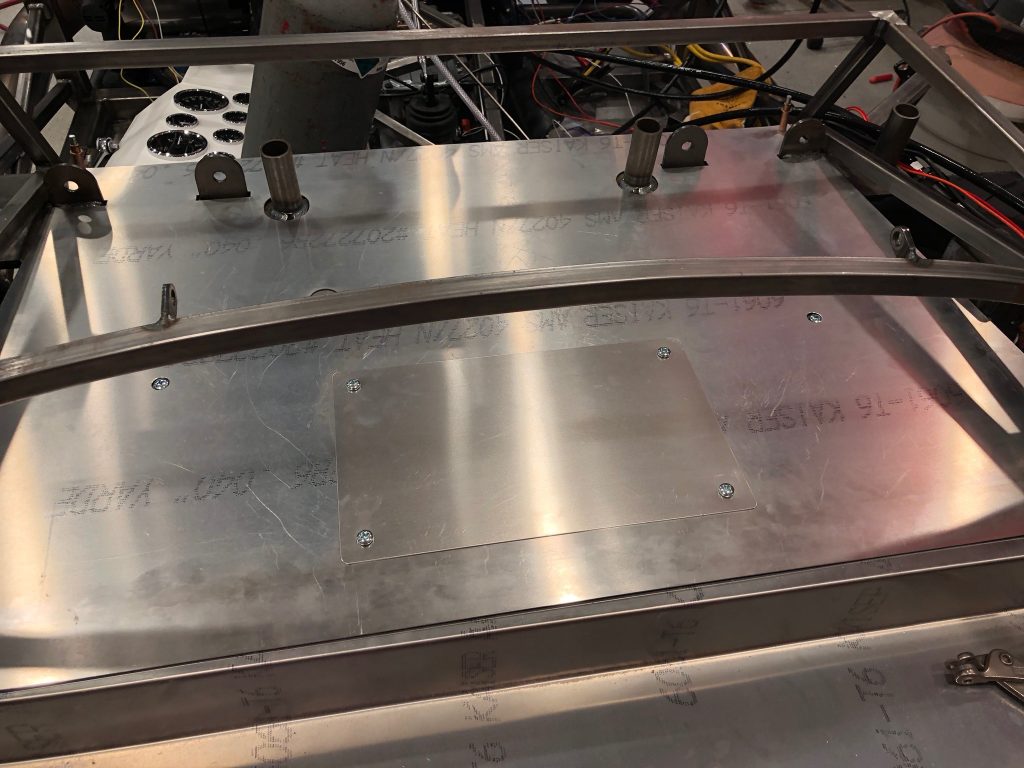

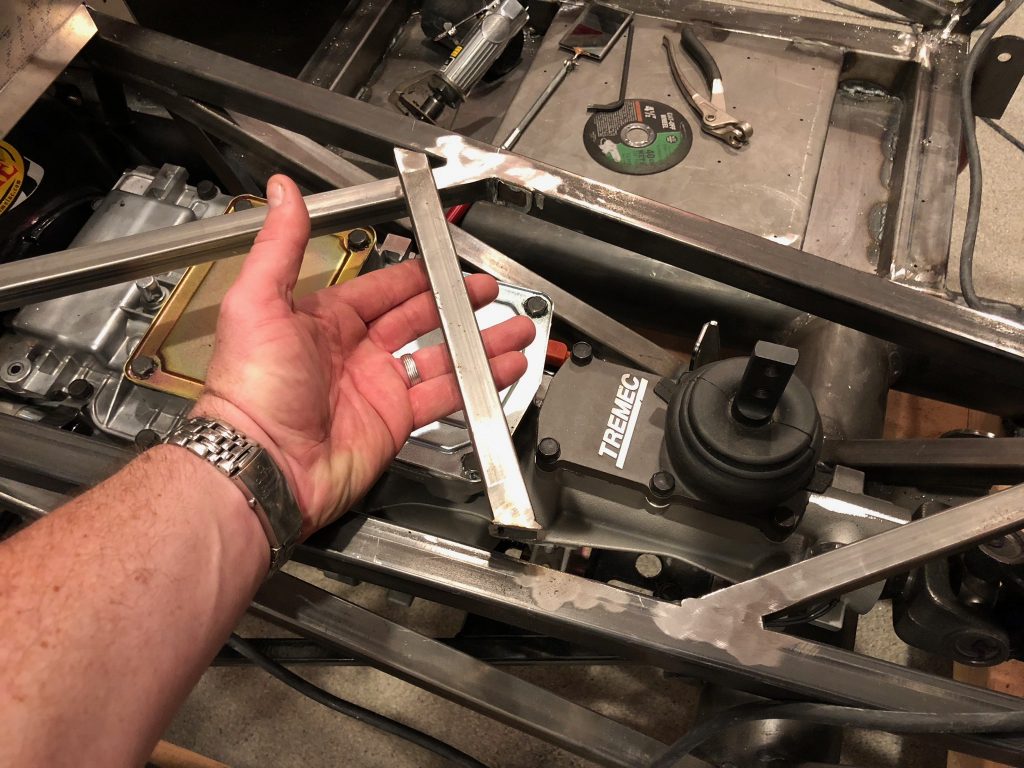

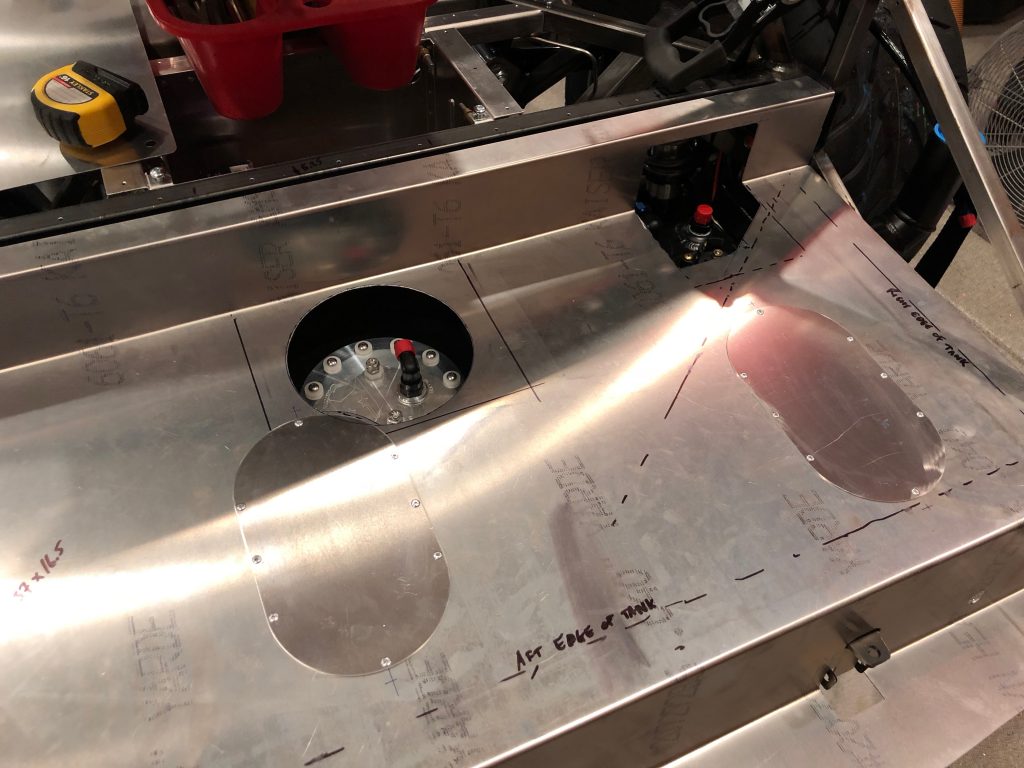

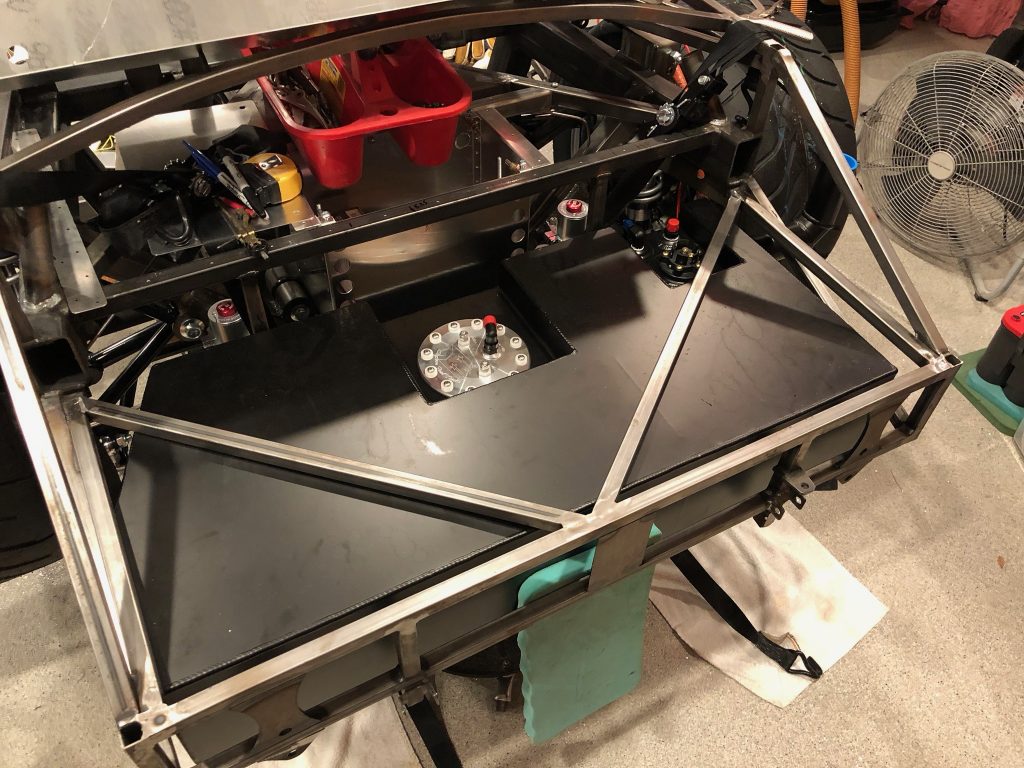

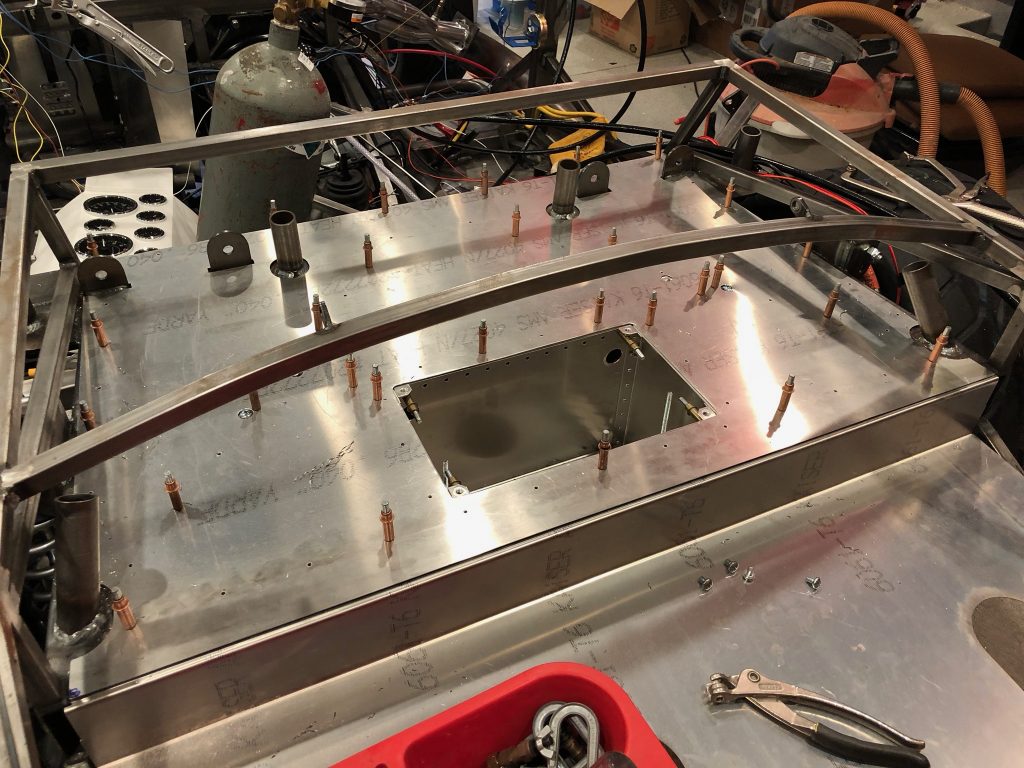

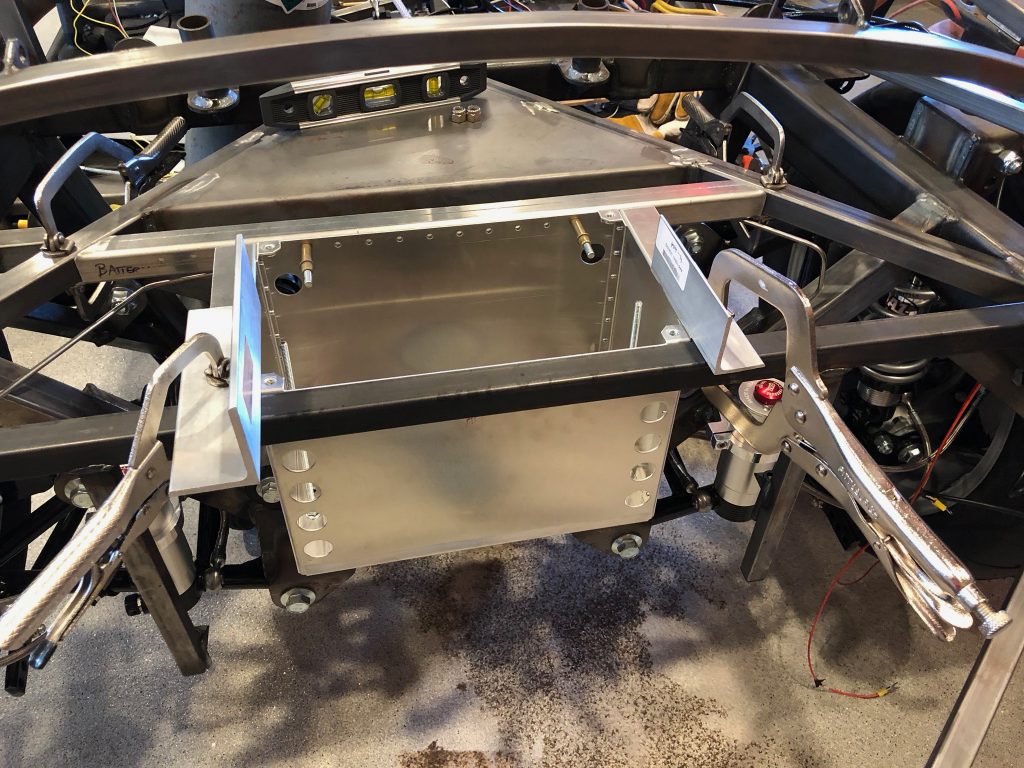

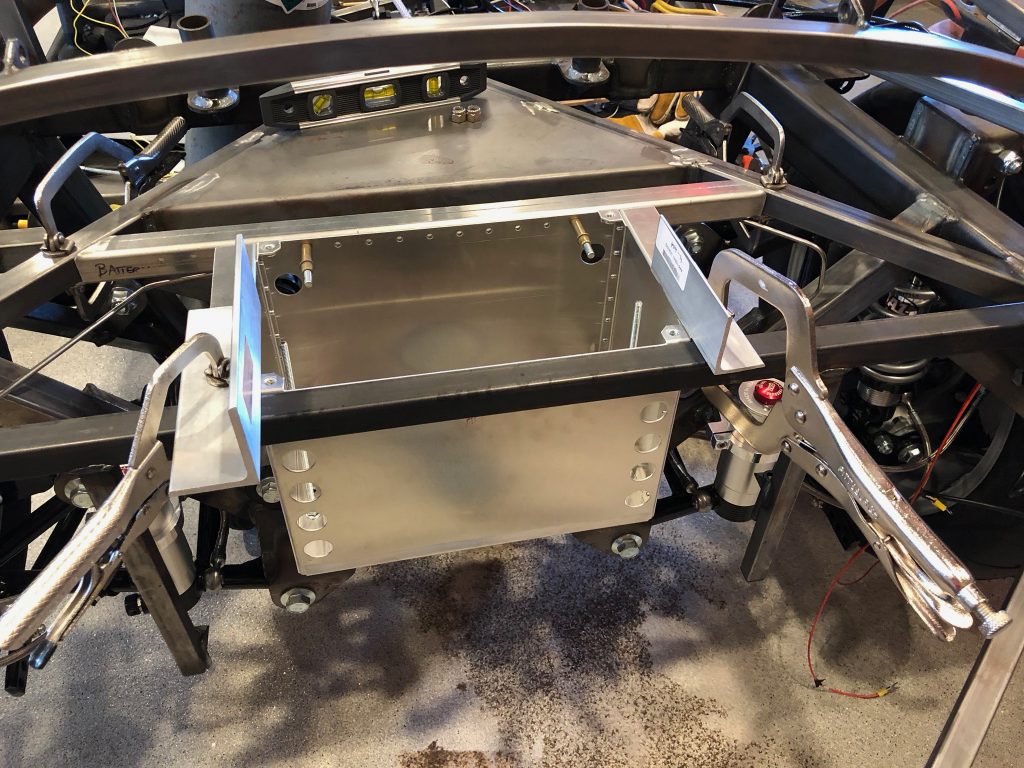

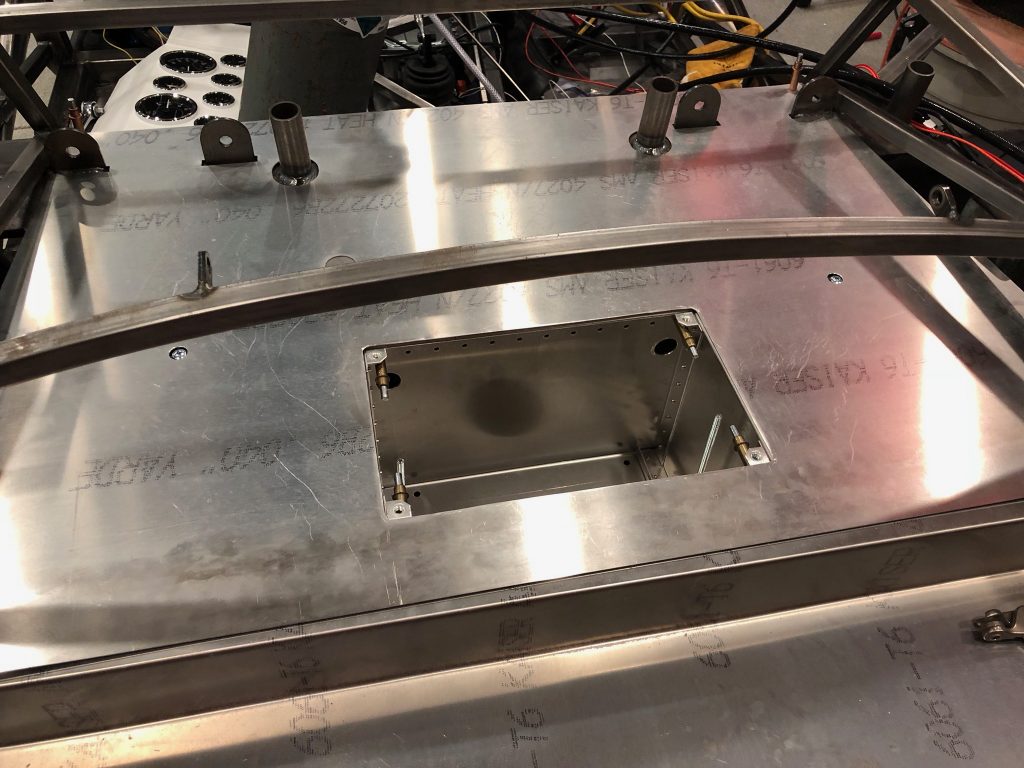

I decided to install the battery box. I disassembled it so that I could debur all of the edges and then riveted it back together. The forward cross bar needed a little trimming to fit between the angled square tubes. I then positioned everything in place and clecoed the box to the cross bar.

After verifying that the box clears the diff mounting ears, I clamped some straight edges to the flanges of the battery box to make sure it was flush with the aft square tube. I then drilled the box to the aft square tube and drilled the cross bar to the angled square tubes.

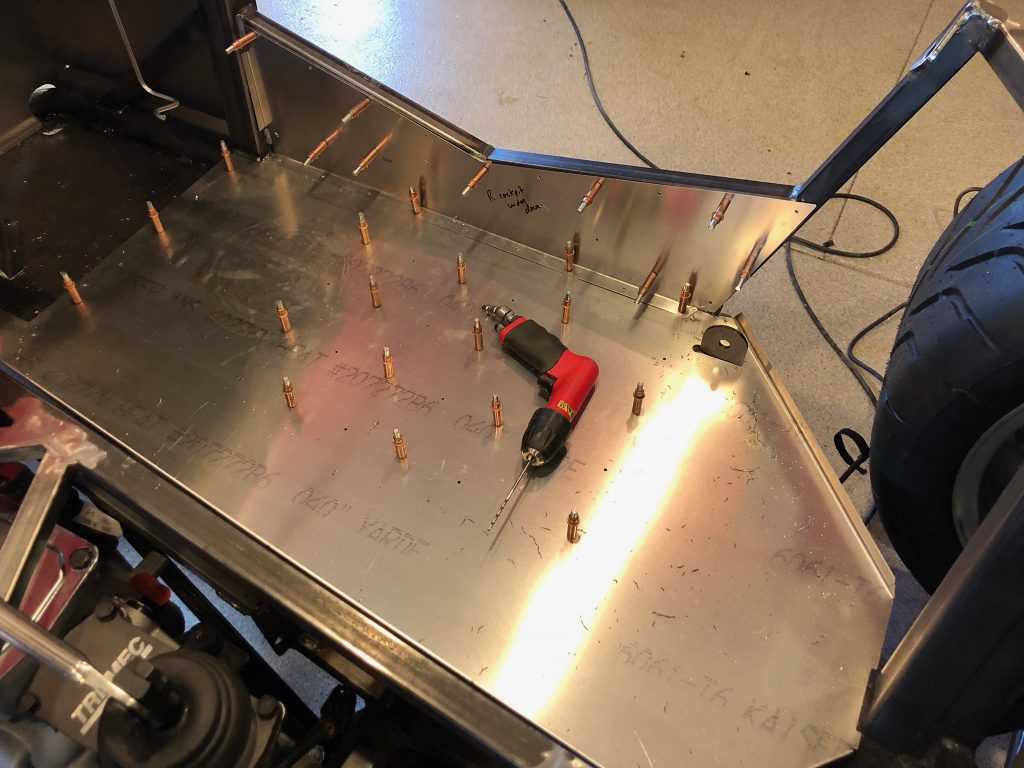

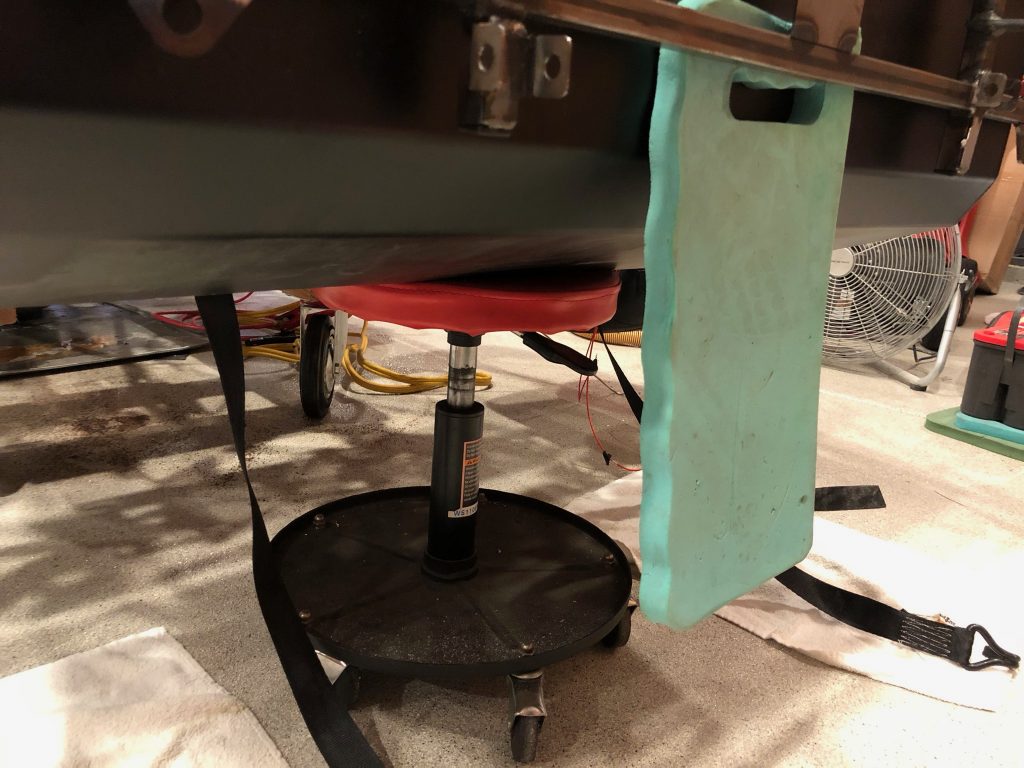

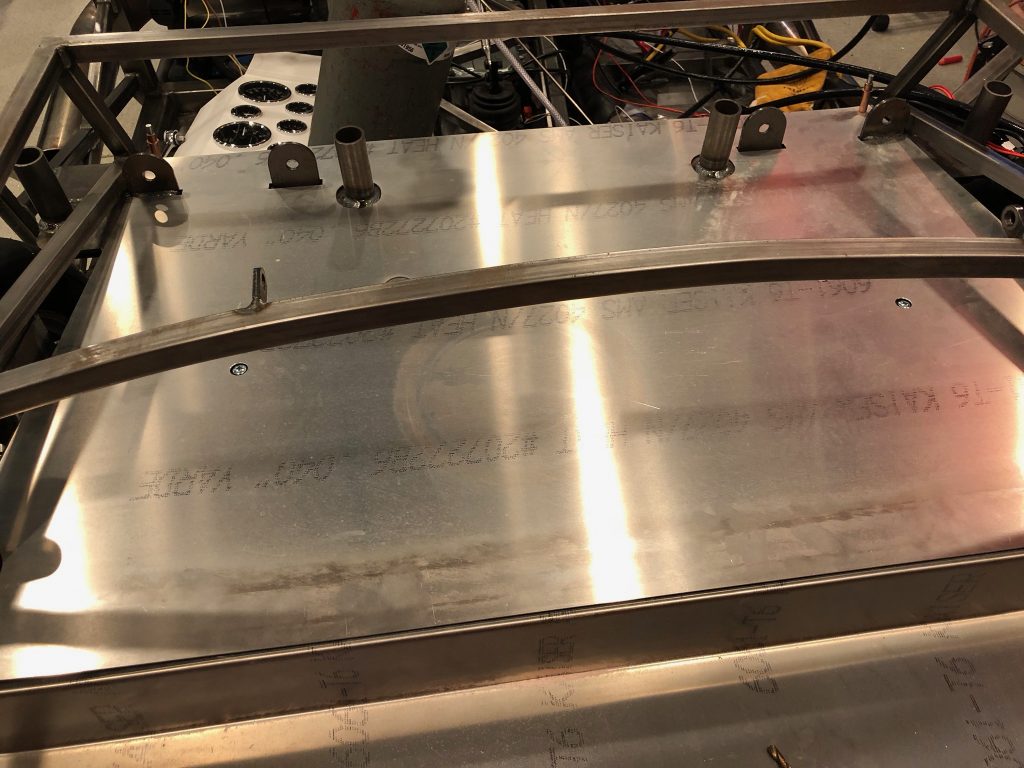

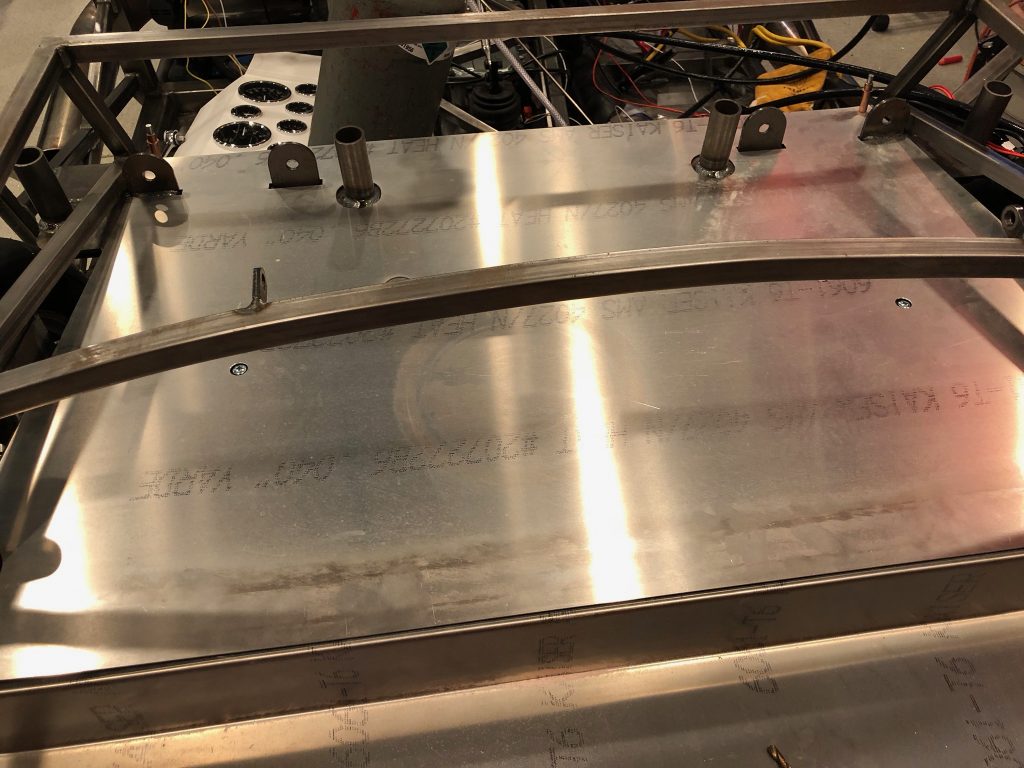

After positioning the floor in place, I drilled a couple of holes at the forward corners to lock in the position, then marked and drilled the holes that clear the bolt heads holding the cross bar in place.

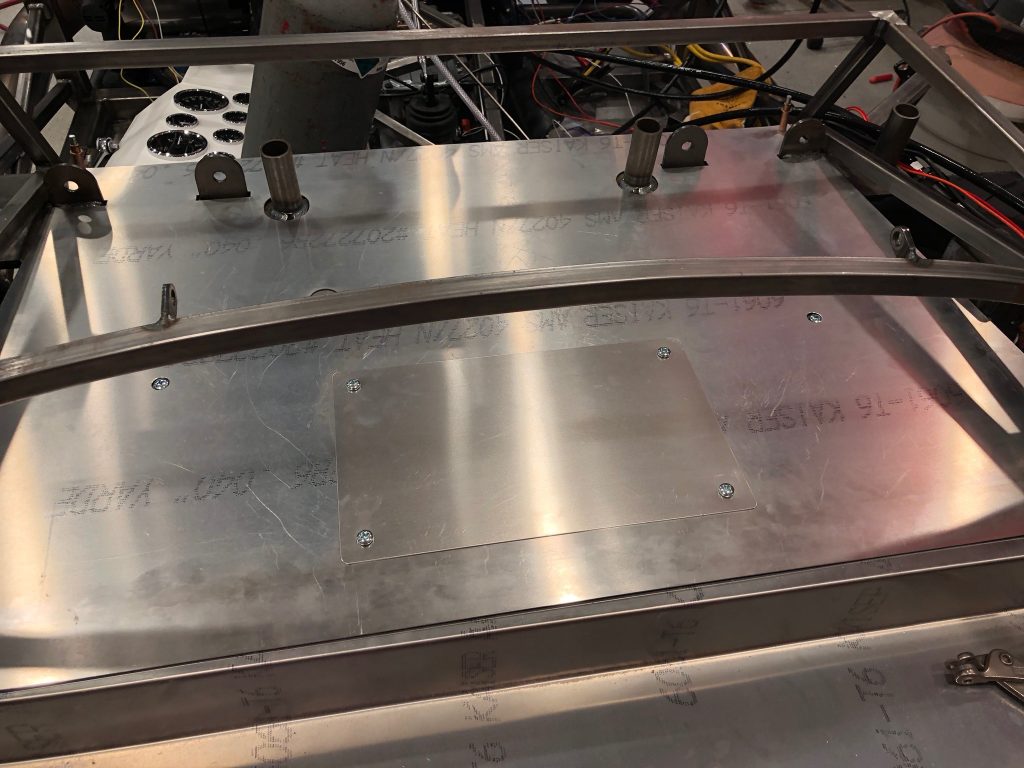

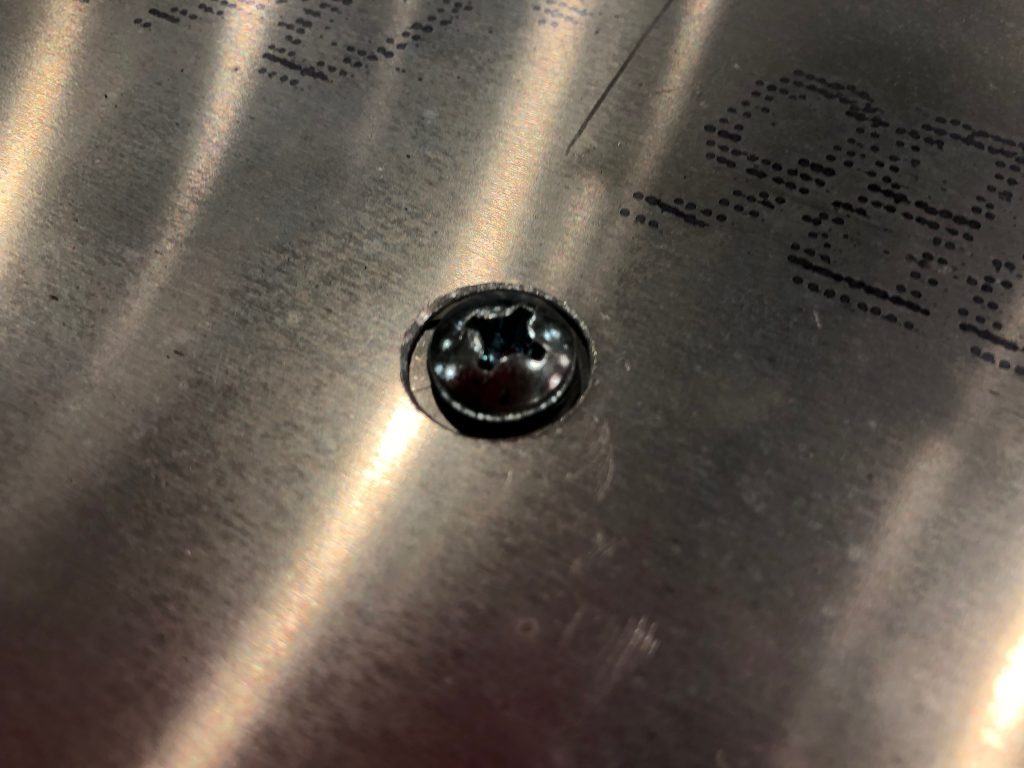

The bolt heads still stick up above the floor slightly, but all of this will be covered by carpet.

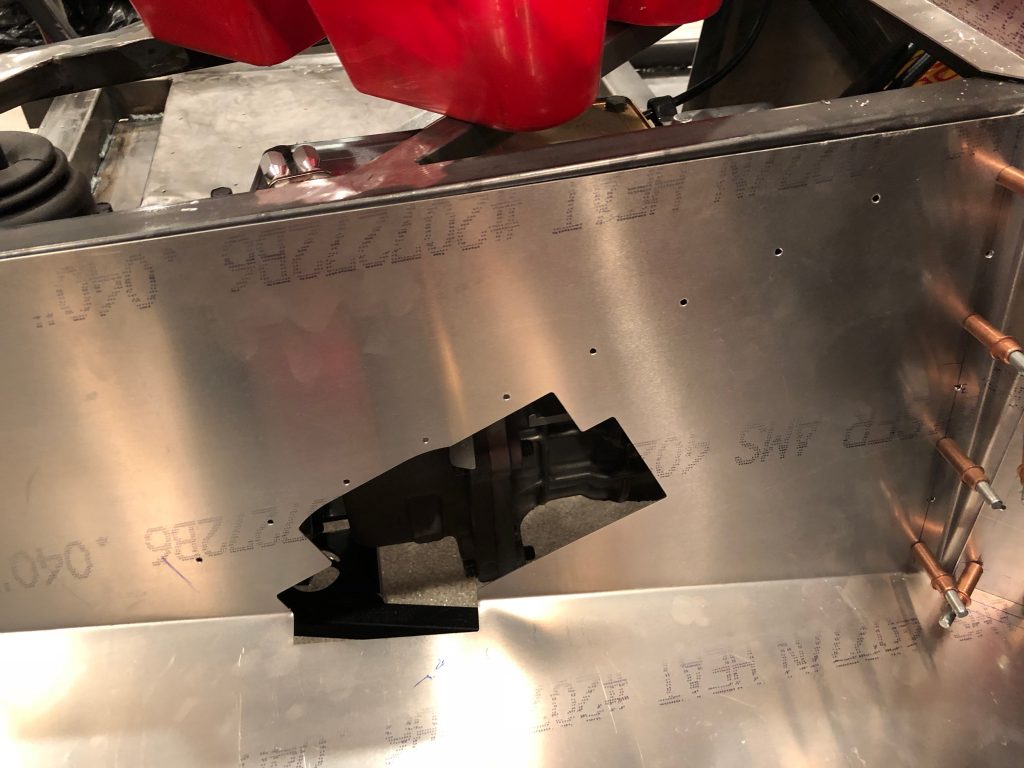

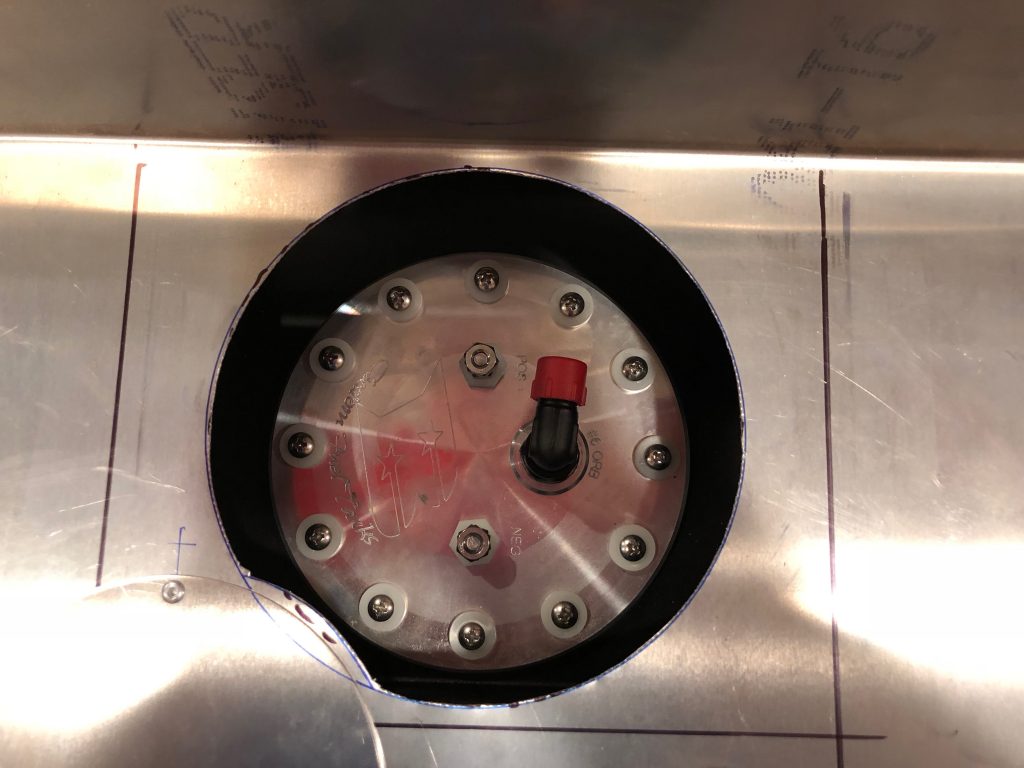

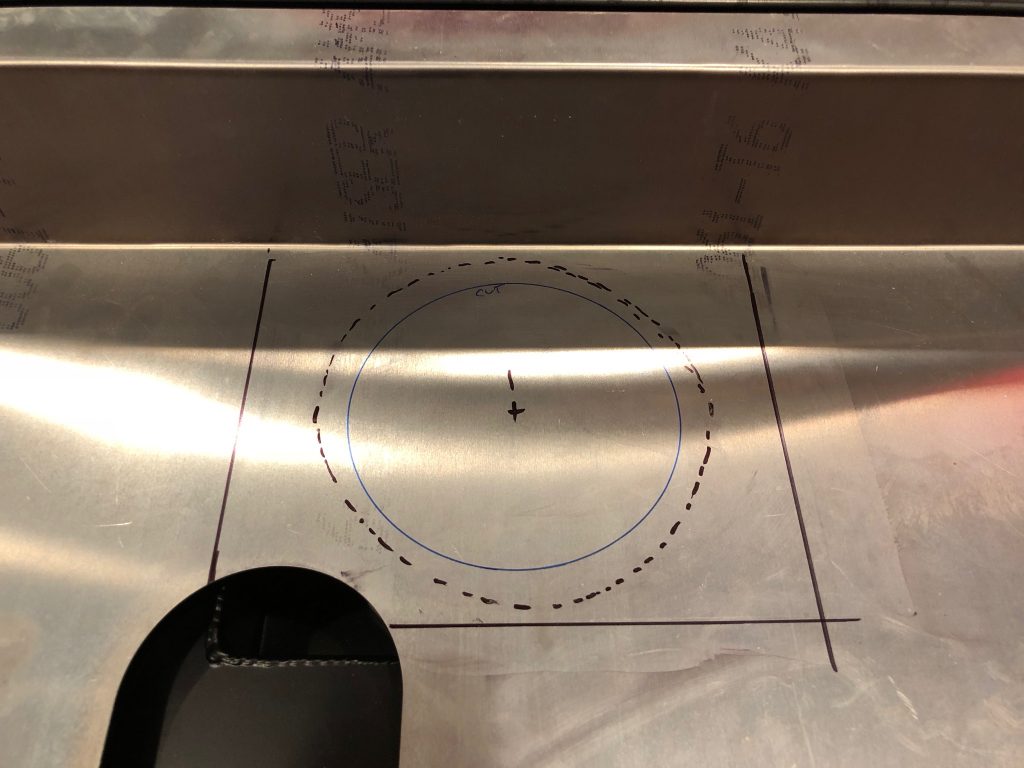

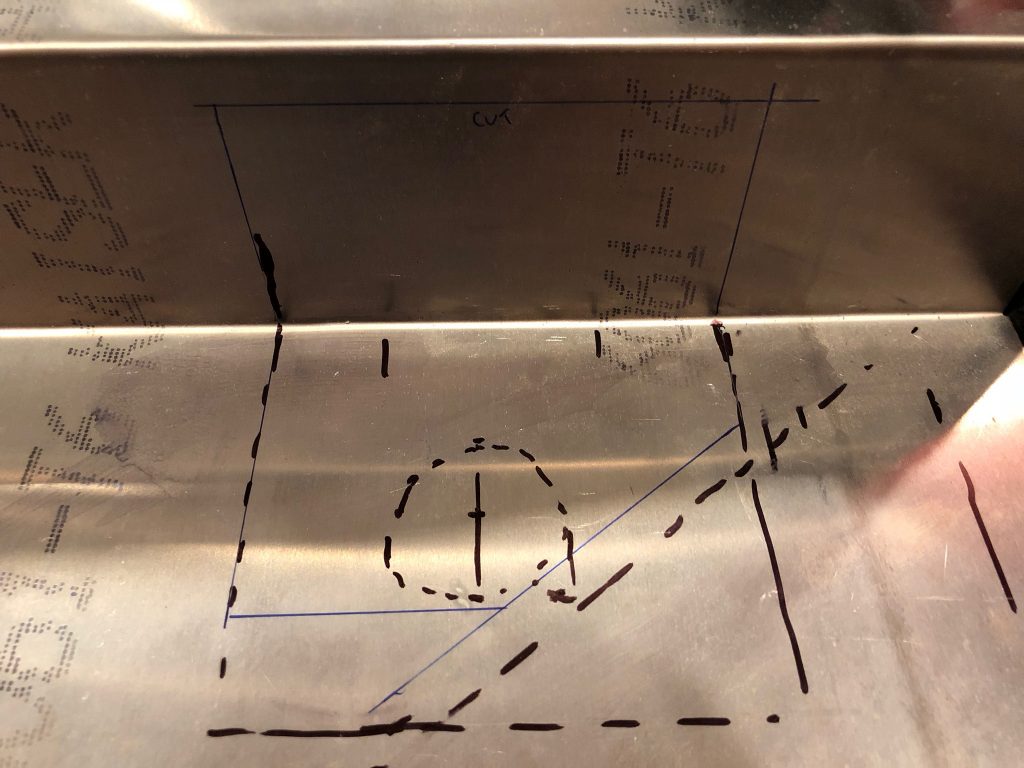

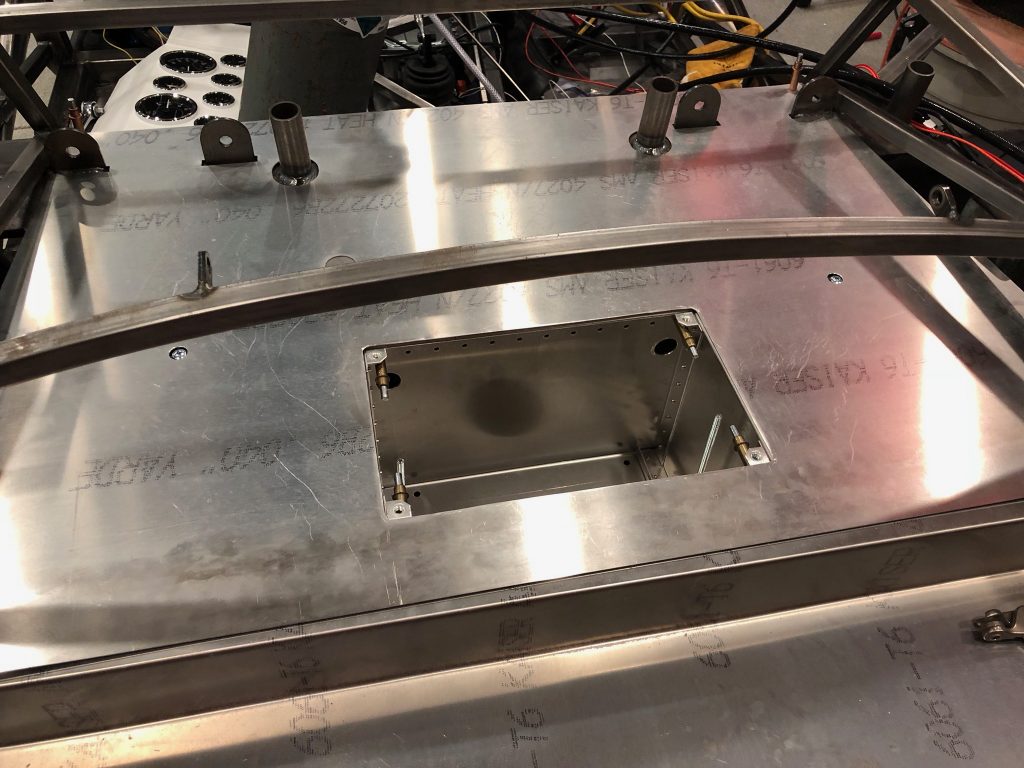

I reached up through the bottom of the battery box and marked the edges for trimming. After cutting out the hole, I test fit the floor in place.

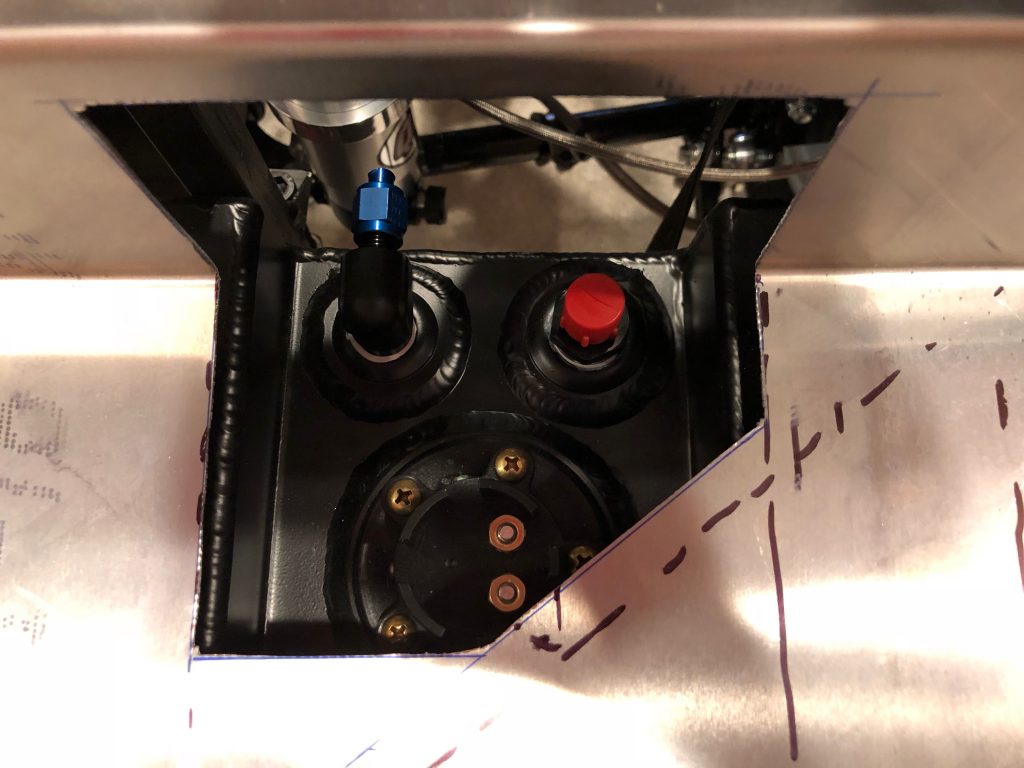

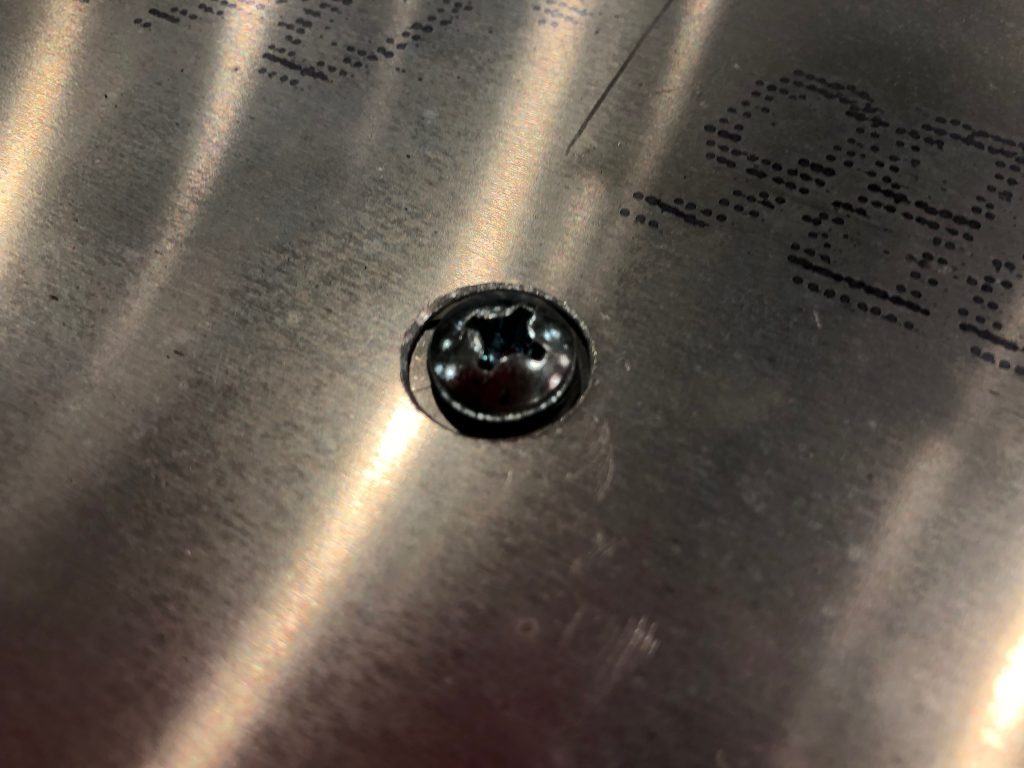

The hole will be covered by a plate that is also held down with button head screws. I briefly considered making these use flush head screws, but I don’t think the extra effort is worth it.