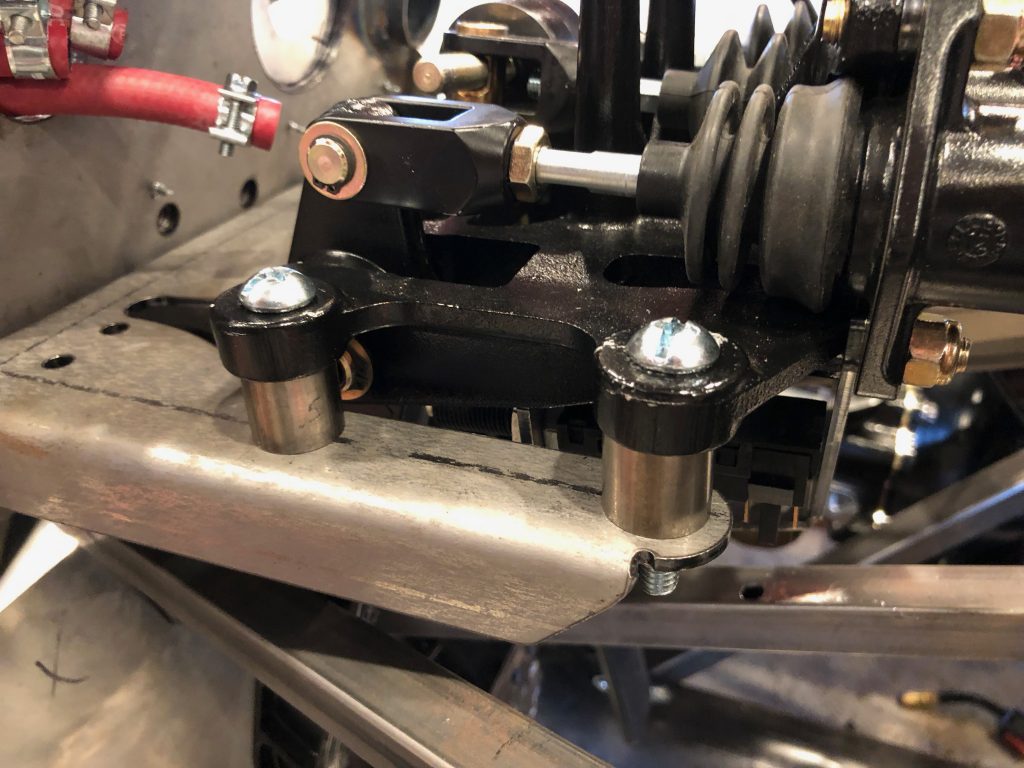

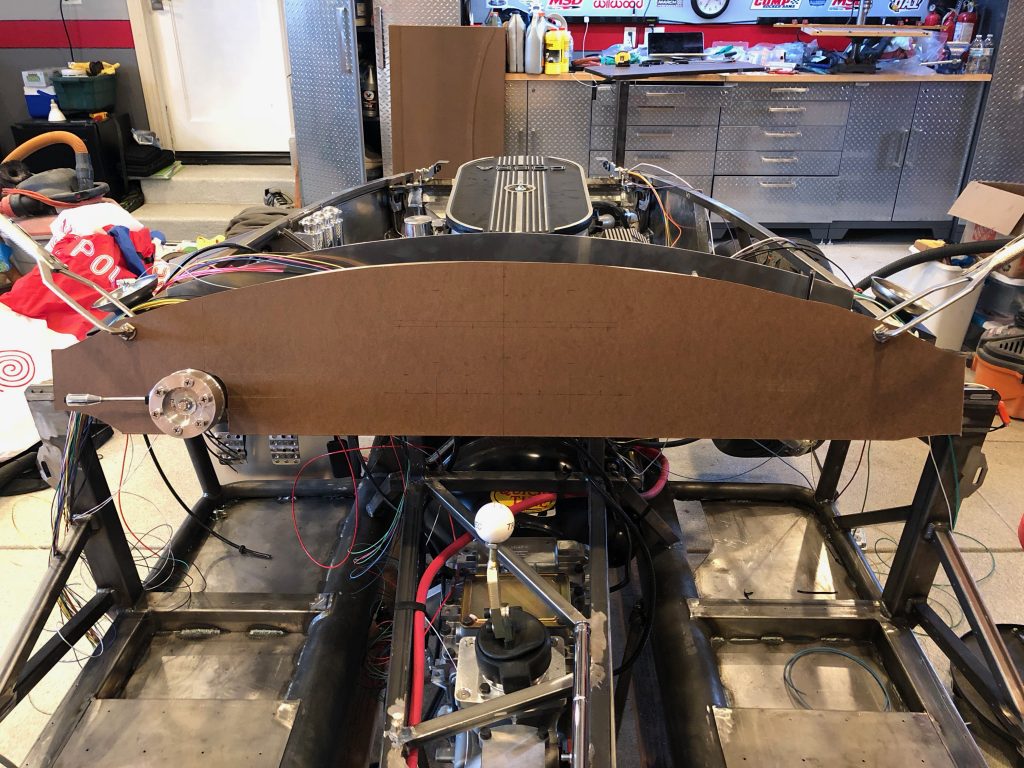

The accelerator pedal was much too close to the brake pedal, so I reversed the arms on the pivot shaft (the pedal arm was to the left of the upper arm). By reversing these, the pedal moves about 1″ to the right. This made the upper arm interfere with the steering shaft, so I put a 15-20º bend in the upper arm to put the upper end in about the same position it was when it was mounted on the other side.

I installed a couple of 1/4-2o rivnuts in the mounting plate so that I didn’t have to try and install a nut on the back side. You can see how much farther the gas pedal is to the right of the brake pedal. It was pretty each to accidentally press the brake pedal and accelerator pedal at the same time before, but now it’s pretty hard. I’m really happy with the pedal spacing now, but it does present another problem. With my foot naturally laying across the accelerator pedal, my shoe goes 2-3″ to the right of the pedal which is well under the left exhaust header.The inner footbox panel on the driver’s side doesn’t have enough room, so I’m going to need to fabricate a new one with a bump out for my shoe.