I picked up a sheet of 18ga steel at a local metal supplier this morning and stopped by the TechShop after work to cut them to size. I ended up deciding to cut each side into two pieces instead of one. Each side has a long, rectangular piece and a short, rectangular piece with a radiused corner.

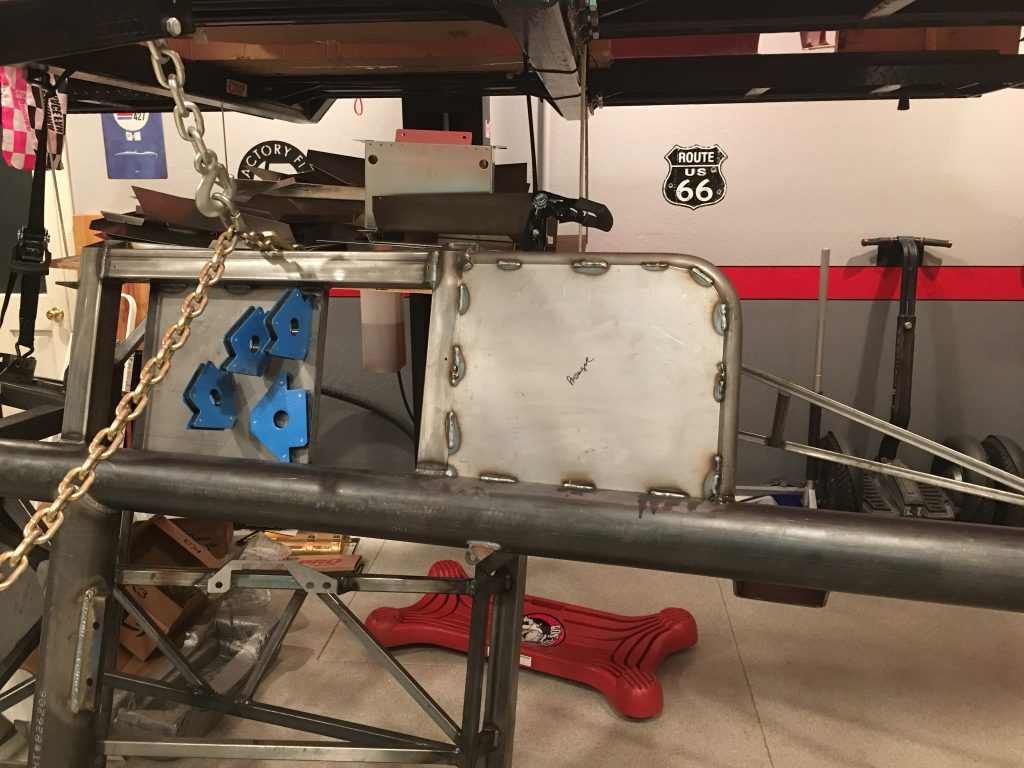

I test fit each of the panels.

The corner radius was not quite right, but it will work just fine.

The only modifications I needed to do were to clip the corners to clear the existing welds.

I set up the welder with the solid core wire and CO2/Argon gas bottle and welded the panel in place. I played around with different voltages/wire feed speeds until I found settings that worked pretty well.

Not all of the welds looked this good, but they should all be plenty strong. It was too late to weld in the other floorboards, so that will have to wait until tomorrow.