We’re going to need the fuel tank for the engine dyno run since the dyno shop is not set up to run EFI engines. The simplest solution is to bring my own tank and let the FiTech unit drive the integrated pump. Before I put fuel in the tank though, I need to get it powder coated since I wouldn’t want to put a tank with fuel vapors in the powder coating oven.

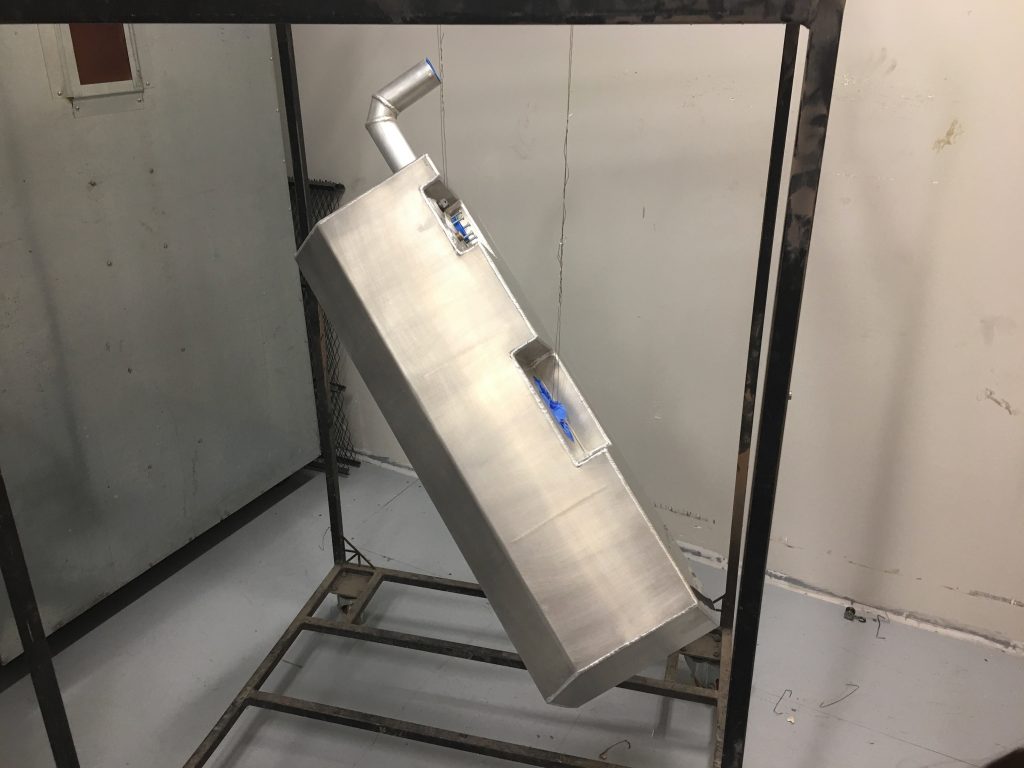

I pulled the fuel pump so that I just have the bare tank and then used some scotchbrite pads to rough up the surface to give the powder coating a better grip. After cleaning the tank thoroughly with solvent, I hung it from a couple of the trolleys in the loading rack.

After giving it a thorough coating of powder, I transferred it into the oven.

After 30 minutes or so at 400ºF, I transferred it back to the loading rack and set it in front of the exhaust racks to get some cooling airflow.

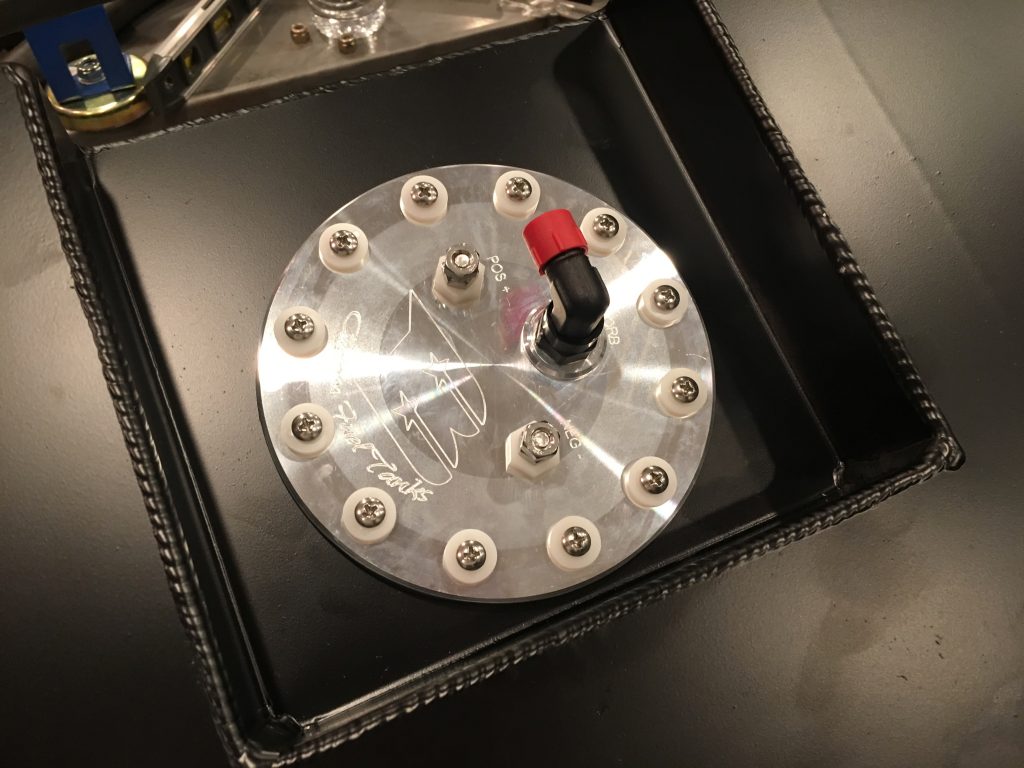

After bringing it home, I reinstalled the fuel pump and fuel outlet fitting.

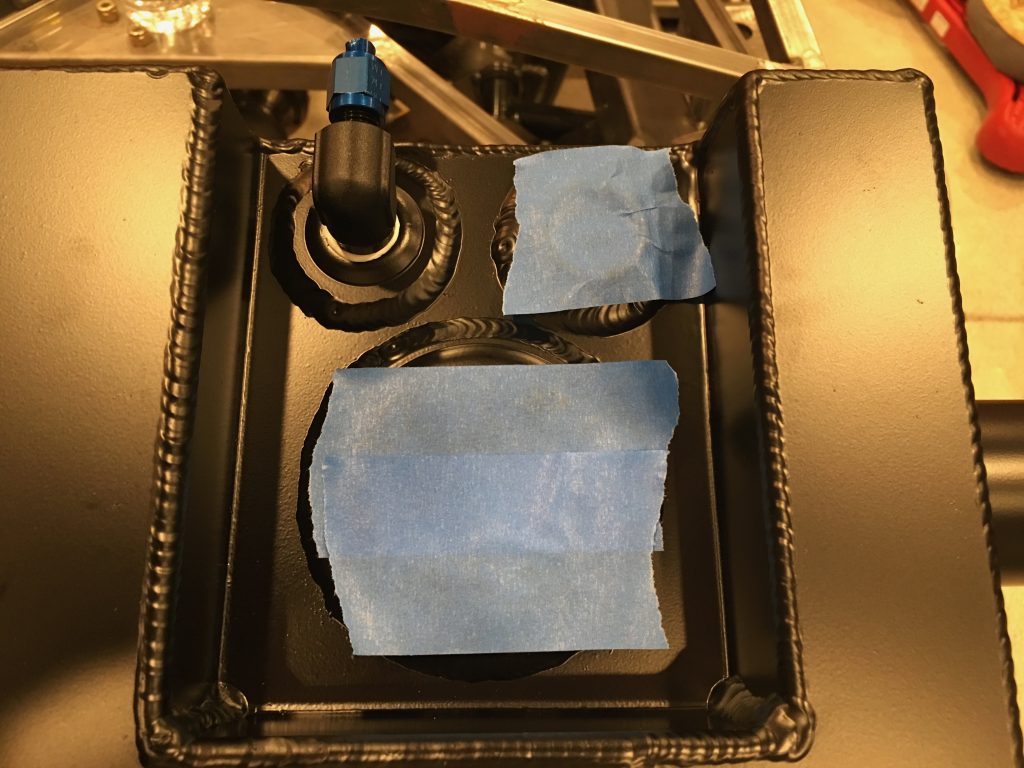

I also installed the fuel vent fitting and capped it until I am ready to hook it up.

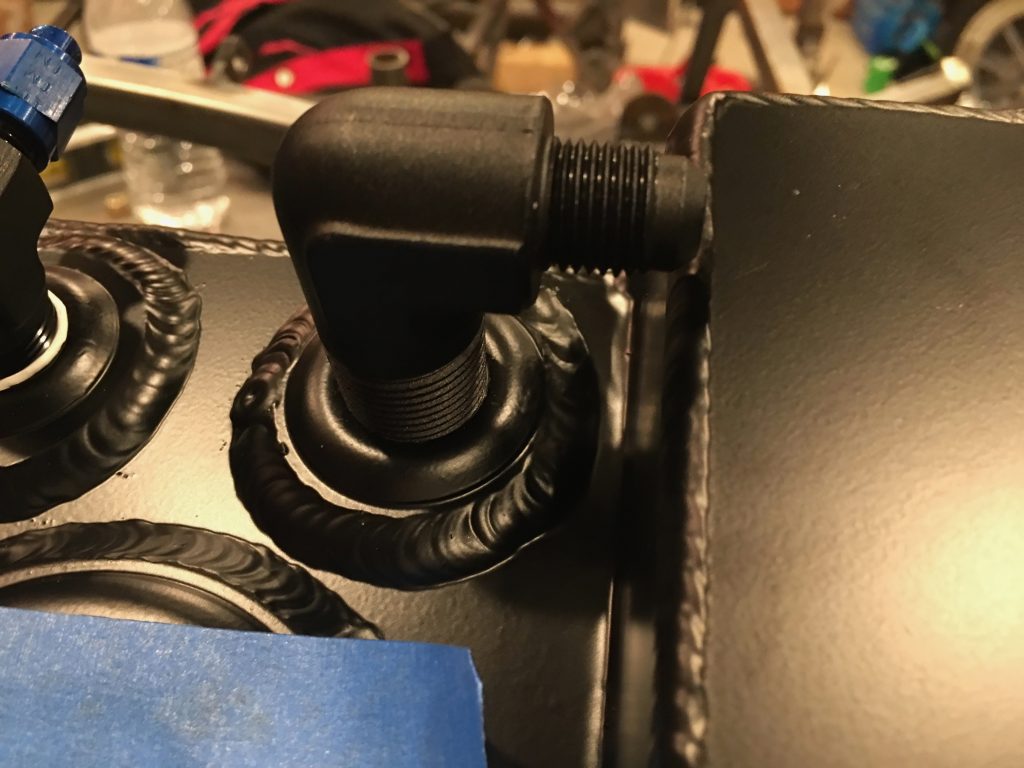

I purchased a 90º angle for the fuel return, but unfortunately it won’t work since Boyd put the boss too close to the side wall of the recess. A straight fitting would obviously thread in fine, but I think it would push the hose up too high since the top of the tank will only sit 3/4″ below the trunk floor. I’ll have to figure out another solution here.