I removed the seat and drilled the final hole through the floor and rear 2″x2″ square tubing.

Afterward, I removed the aluminum floor to get access to the steel floor underneath.

The bolts that attach the outer seat track will go all the way through the lower part of the square tubing. I used the bubble level in the rear of the drill to ensure I was drilling perpendicular to the top surface and then drilled through the bottom surface.

I also drilled through the lower floor the same way.

Afterward, I used the unibit to enlarge these holes to just over 1/2″.

I’m going to be putting pieces of 1/2″ OD steel tubing through these holes and welding them to the upper and lower surfaces before grinding them flat. It’s too late to run the grinder tonight, so I’ll take care of that tomorrow. The spacers will allow me to tighten the bolts properly without deforming the metal. This isn’t much of a concern with the rear 2″x2″ tubing since it has fairly thick walls, but it’s really important with the forward hole through the two thin pieces of sheet steel.

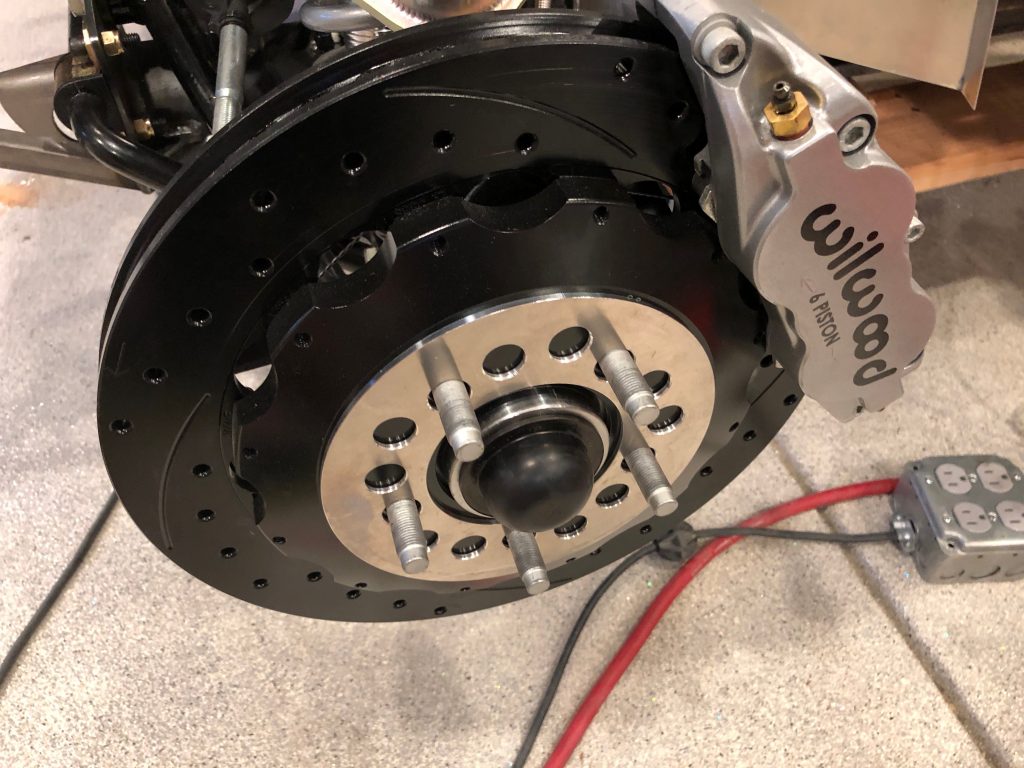

I’ve been concerned with how little space there is between the front brake calipers and the inside of the wheel. If there is even the smallest amount of flex in the wheel, the wheel could hit the caliper. To pick up some extra space, I picked up some new 0.125″ aluminum spacers. These are nearly 0.040″ thicker and quite a bit lighter.

Here is one of them installed. The only disadvantage is that these are made from shiny aluminum and are visible between the spokes of the wheel.

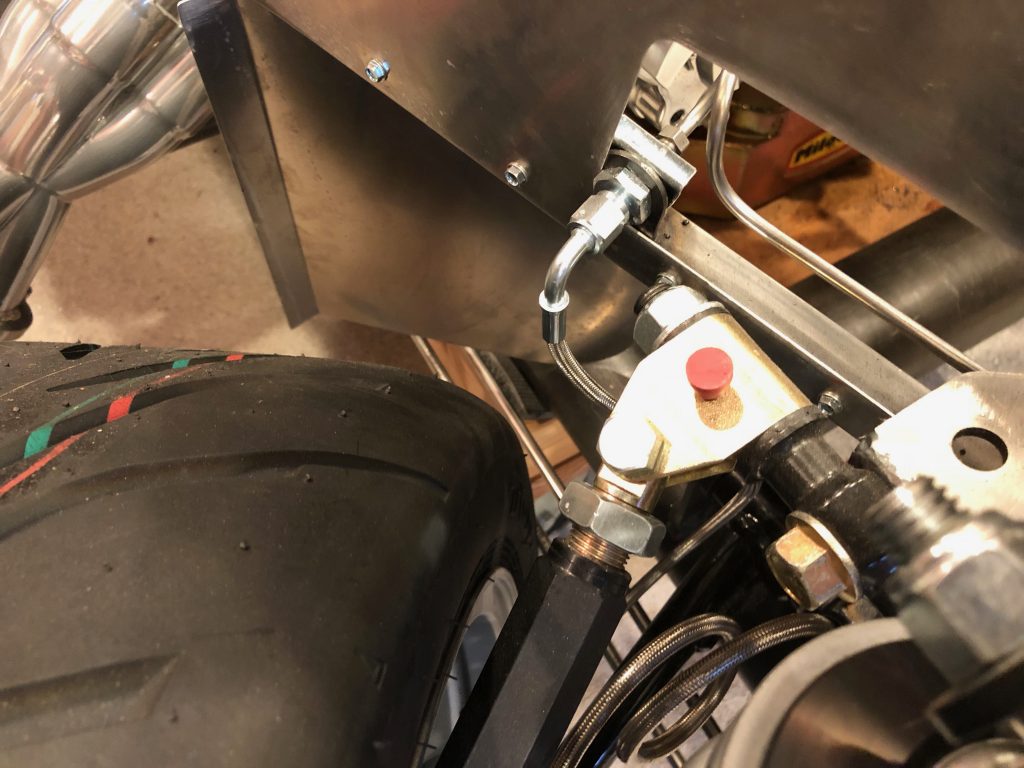

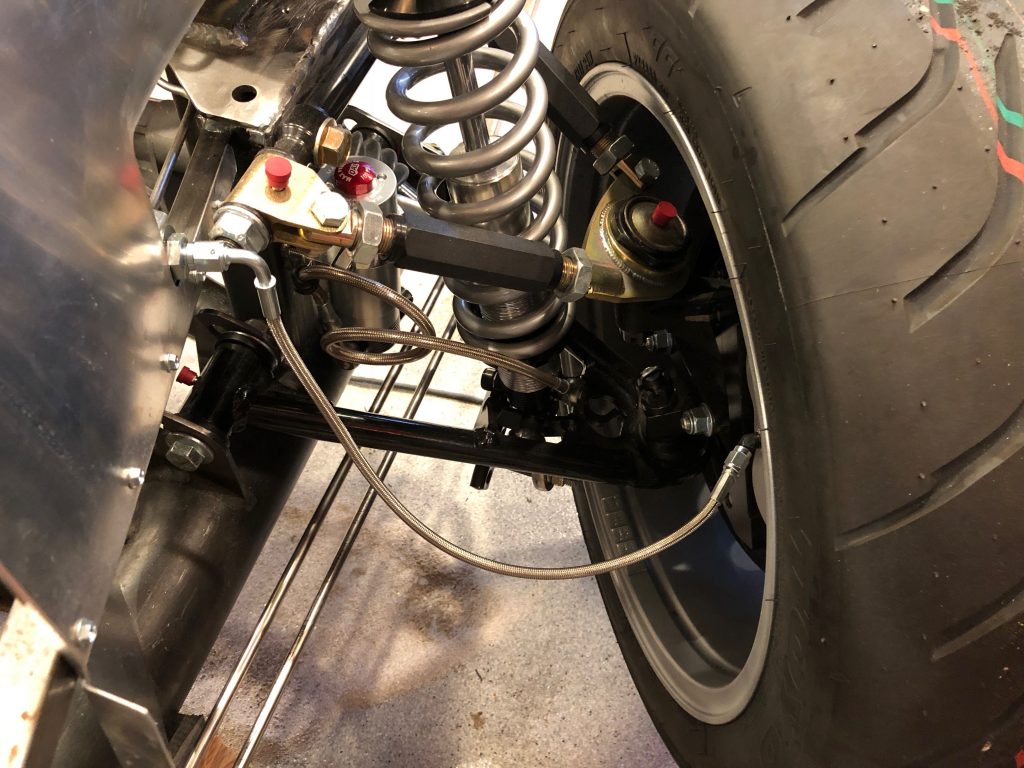

I noticed a while back that my front brake hoses are hitting the tires when turned to the steering stops, so I need to replace these. They’re also 18″ long which is longer than is necessary.

I picked up a couple of 16″ brake hoses with a 90º fitting at one end. Even with the wheel all the way to the stop, there’s plenty of room between the tire and hose.

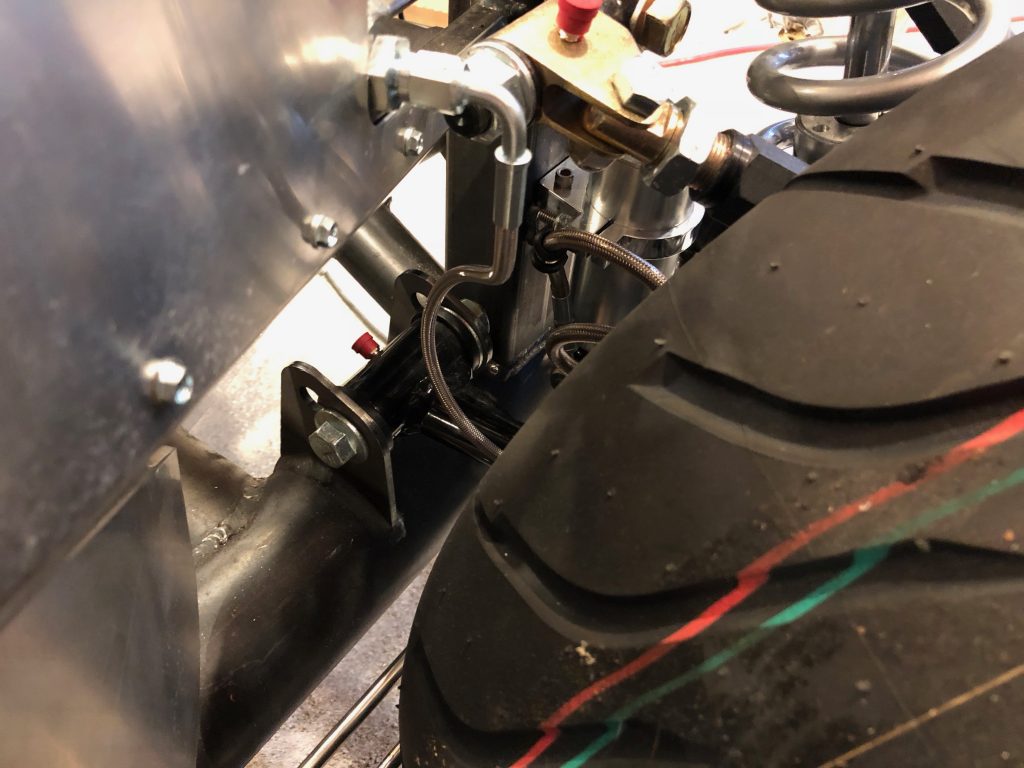

The hose misses the tire and chassis as they wheel is turned from stop to stop.

When the wheel is at the other stop, there’s plenty of slack in the cable.