My dad stopped by this morning and we did what we’re calling a “virtual engine build”. We test fit most of the components and verified we had all of the right parts and the right bolts to fasten them on. We also confirmed we had the right sealants, tools and torque settings.

We got started on the bottom end, fitting the oil pump, oil pickup and oil pump driveshaft. We then fit the oil pan and confirmed we had the right clearance between the pickup and the bottom of the pan by taping over the oil pickup and using a small piece of modeling clay. The only issue we ran into was that one of the nuts in the ARP oil stud kit had the wrong thread pitch. I’ll have to call them on Monday and get a replacement.

We then fit the timing chain cover and water pump. Although the ARP bolt kit I ordered from Summit Racing said in contained both timing chain cover bolts and water pump bolts, there were a bunch of missing 5/16″x18 bolts: 2@1.5″, 2@2″, 1@2.75″, 1@3.5″ and 1@5″. ARP said to contact them if the bolt set didn’t contain everything we needed, so hopefully they’ll send these or sell them individually to us. We also confirmed there will be clearance between the harmonic balancer and the water pump. The only potential issue we may have is that I purchased a timing pointer that mounts at the 2 o’clock position which is right under the water pump inlet. I *think* we’ll still be able to read the timing marks after the harmonic balancer is installed, but I may have to purchase one that mounts at the 11 o’clock position.

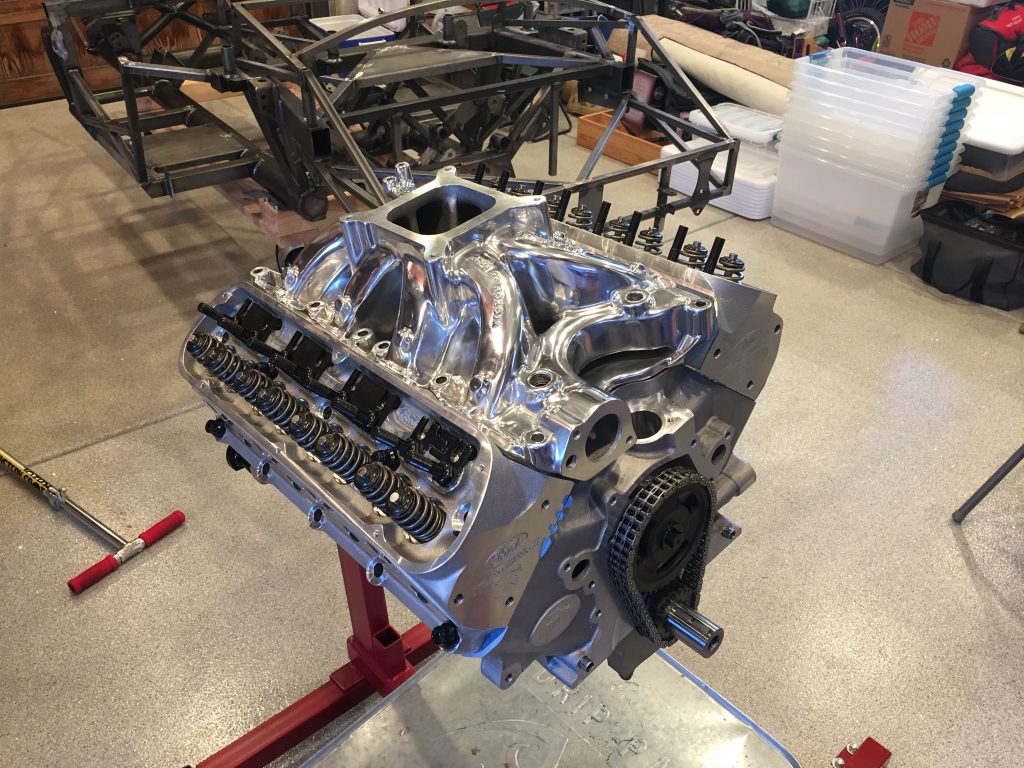

Finally, we mounted the heads and intake manifold. I’m trying to use all ARP 12pt stainless hardware for this engine build, but unfortunately, ARP doesn’t make stainless head bolts or studs for the 351W. They do for other engines, but apparently there hasn’t been much demand for them with this engine. They do may black oxide bolts and studs, but mostly with hex heads. The only option for 12pt hardware is studs. Given how far back the engine sits in the Cobra, the only disadvantage to studs is that I won’t be able to remove the heads with the engine installed in the car since the heads have to slide straight out until they can clear the studs. I really don’t think that will be an issue. I really like the studs though since they allow full thread engagement in the block and the thread bearings surface will the fine-pitch threads on the studs instead of course-pitch threads in the block.

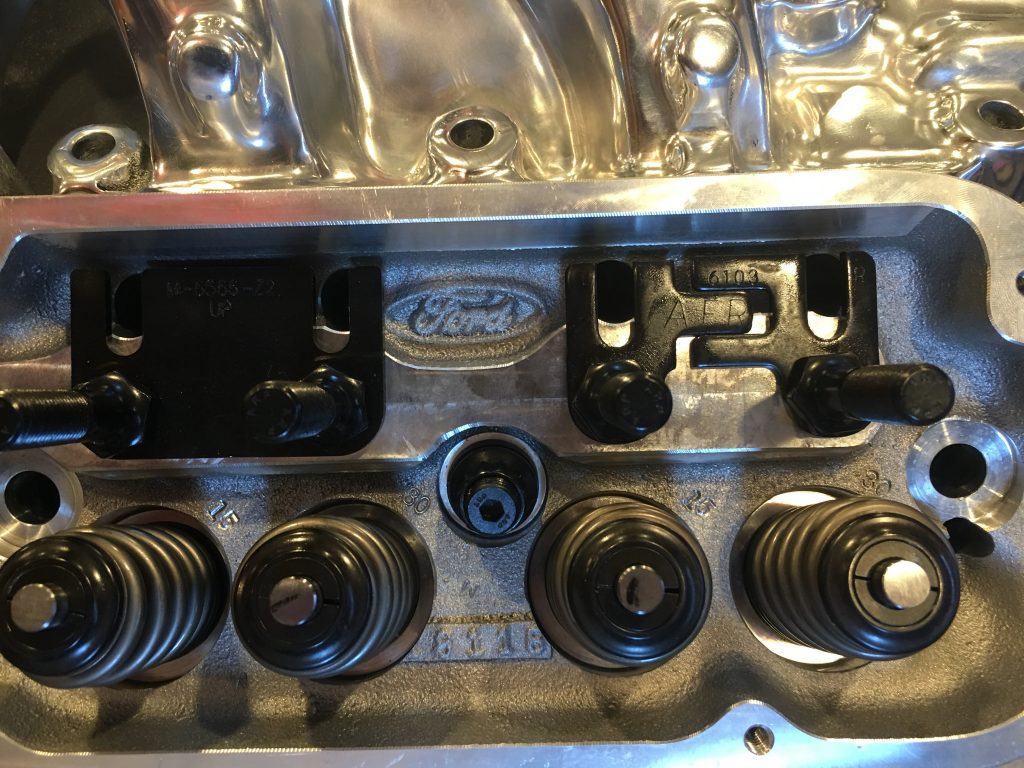

One issue we ran into a couple of weeks ago was the rocker alignment on the valve stem. With the stock guide plates, the rockers were not perfectly aligned with the ends of the valve stems but were hanging somewhat off to one side. I purchased a set of AFR adjustable guide plates which gave me the ability to independently adjust the alignment of the intake and exhaust rockers. You can see the difference between them in the picture below. With these, I was able to adjust the rockers to be perfectly in the center of the valve stems.