I started installing the throttle linkage tonight. One disadvantage to installing the linkage directly to the 2″x2″ tubing is that it causes the linkage to sit at an angle. I tried installing it to the lower portion of the throttle arm which changes the throttle action from pull-to-increase to a push-to-increase, but the geometry made it nearly impossible to hit full throttle. By installing it to the upper portion of the throttle arm with a the pull-to-increase throttle action, it’s easy to move it through the full throttle range.

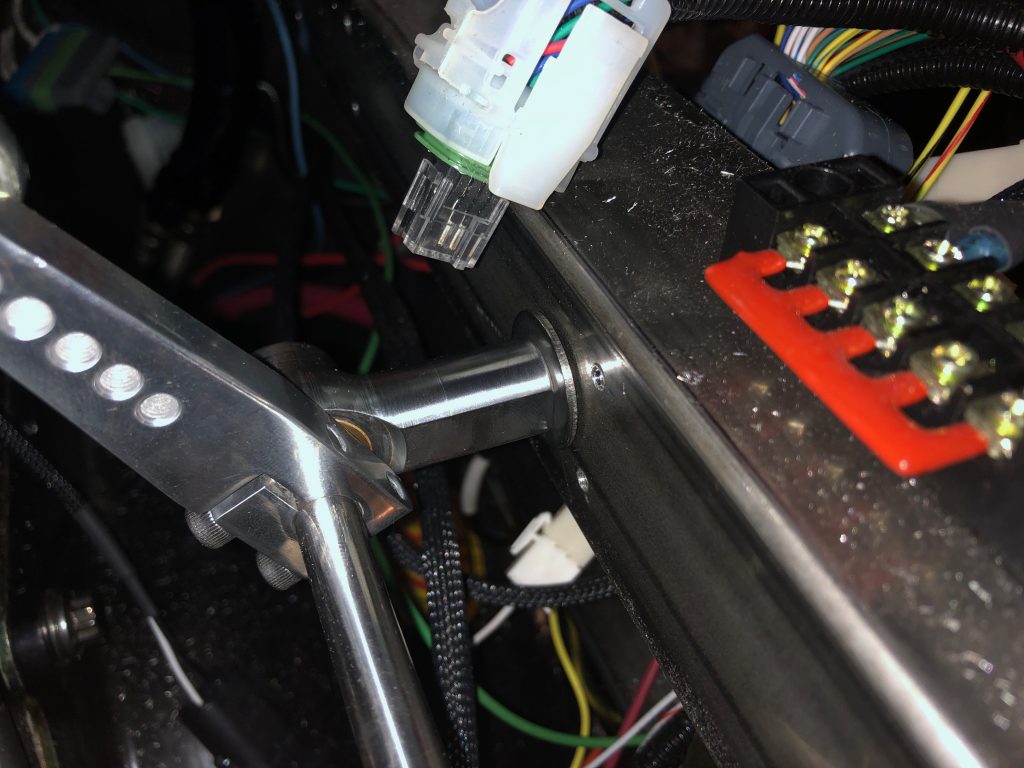

I installed two 3/8″ rivnuts into the 2″x2″ square chassis tubing. The first one is almost directly behind the throttle arm so that the linkage is parallel with the valve covers. I used some 2″ pieces of 3/8″-24 stainless all-thread to attach the rod end bearings to the tubing. The throttle linkage is connected to a throttle arm from Speedway that attaches to a 12″ pieces of stainless rod.

The other end of the stainless rod goes through the second rod end bearings that’s installed inside the driver’s footbox. There is a second Speedway throttle arm here with another linkage to the accelerator pedal.

I haven’t hooked up the forward end yet because the throttle pedal is drilled for #10 screws and I inadvertently ordered a rod end linkage with a 1/4″ stud. I might try drilling this out before ordering more parts.